Coating for inner wall of styrene tank

A technology of styrene and coatings, applied in the direction of coatings, etc., can solve the problems of quality impact, lack of polymerization inhibitors, poor resistance to styrene, etc., and achieve the effect of high cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

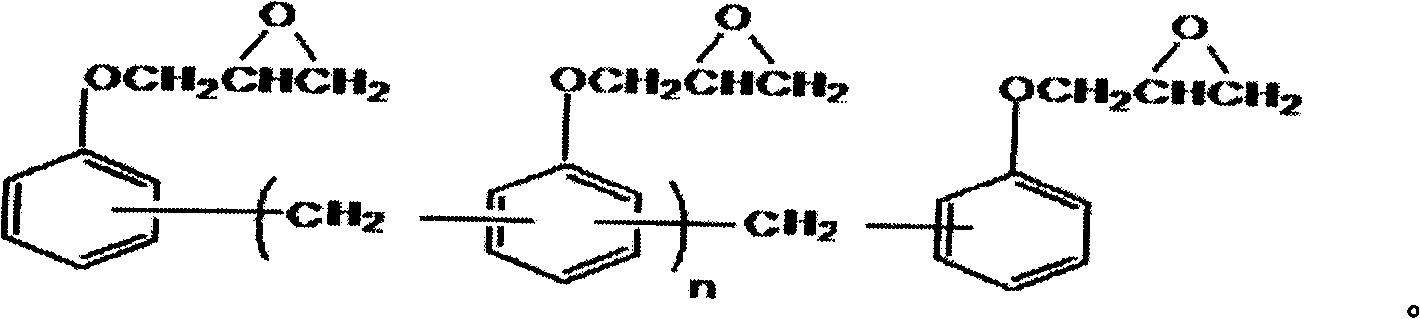

Method used

Image

Examples

Embodiment 1

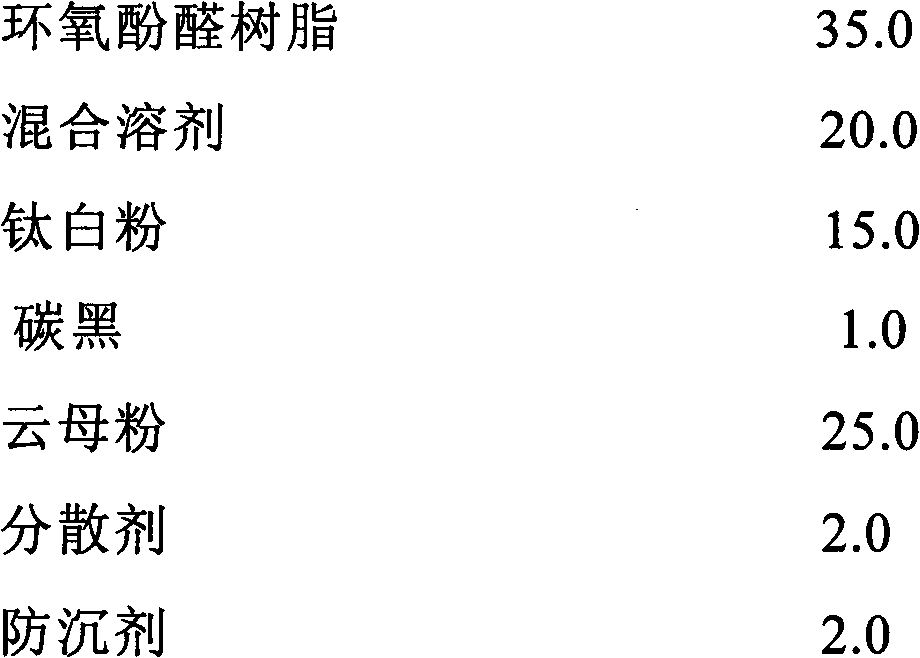

[0038] The formulation of component A of the primer is as follows:

[0039]

[0040] The formulation of the primer component B is as follows:

[0041] Cardanol epoxy curing agent 16.5

[0042] n-Butanol 8.5

[0043] A component: B component = 1:4.

[0044] production process:

[0045] Component A: In the container, add novolac epoxy resin and mixed solvent, stir evenly, then add pigment, filler dispersant and anti-sedimentation agent in turn, enter the sand mill and grind to a fineness ≤ 40 pm to obtain component A.

[0046] Component B: In a dry and clean container, add epoxy curing agent and solvent n-butanol, stir evenly to obtain Component B.

[0047] Mix component A and component B at a weight ratio of 4:1 to obtain a styrene tank interior coating.

Embodiment 2

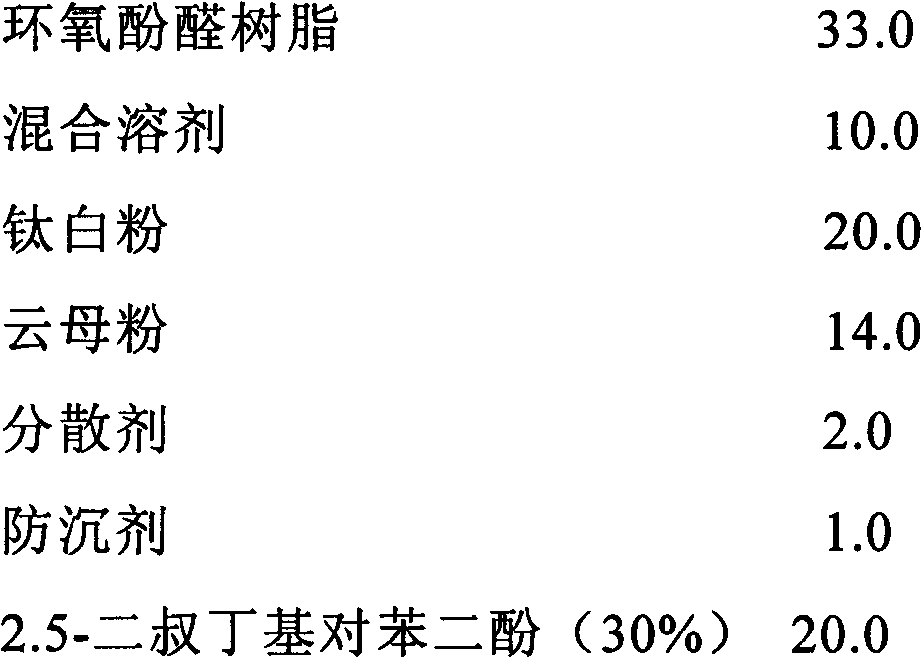

[0049] The formula of component A of the intermediate paint is as follows:

[0050]

[0051] The formulation of the primer component B is as follows:

[0052] Cardanol epoxy curing agent 15.5

[0053] n-Butanol 9.5

[0054] A component: B component = 1:4.

[0055] production process:

[0056] Component A: In the container, add novolac epoxy resin and mixed solvent, stir evenly, then add pigment, filler dispersant and anti-sedimentation agent in turn, enter the sand mill to grind to a fineness of ≤40μm, add 2. After adding 5-di-tert-butylhydroquinone inhibitor, stir evenly to obtain component A.

[0057] Component B: In a dry and clean container, add epoxy curing agent and solvent n-butanol, stir evenly to obtain Component B.

[0058] Mix component A and component B at a weight ratio of 4:1 to obtain a styrene tank interior coating.

Embodiment 3

[0060] The formula of component A of the topcoat is as follows:

[0061]

[0062]

[0063] The formulation of the primer component B is as follows:

[0064] Cardanol epoxy curing agent 23.6

[0065] n-Butanol 1.4

[0066] A component: B component = 1:4.

[0067] production process:

[0068] Component A: In the container, add novolac epoxy resin and mixed solvent, stir evenly, then add pigment, filler dispersant and anti-sedimentation agent in turn, enter the sand mill to grind to a fineness of ≤40μm, and obtain A component.

[0069] Component B: In a dry and clean container, add epoxy curing agent and solvent n-butanol, stir evenly to obtain Component B.

[0070] Mix component A and component B at a weight ratio of 4:1 to obtain a styrene tank interior coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com