Technology for manufacturing automobile door and window sealing strip

A technology for manufacturing technology and sealing strips, which is applied in the field of manufacturing technology for automobile door and window sealing strips, and can solve problems such as consistency, difficulty for workers to master the process method, uneven thickness of TPE composite layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

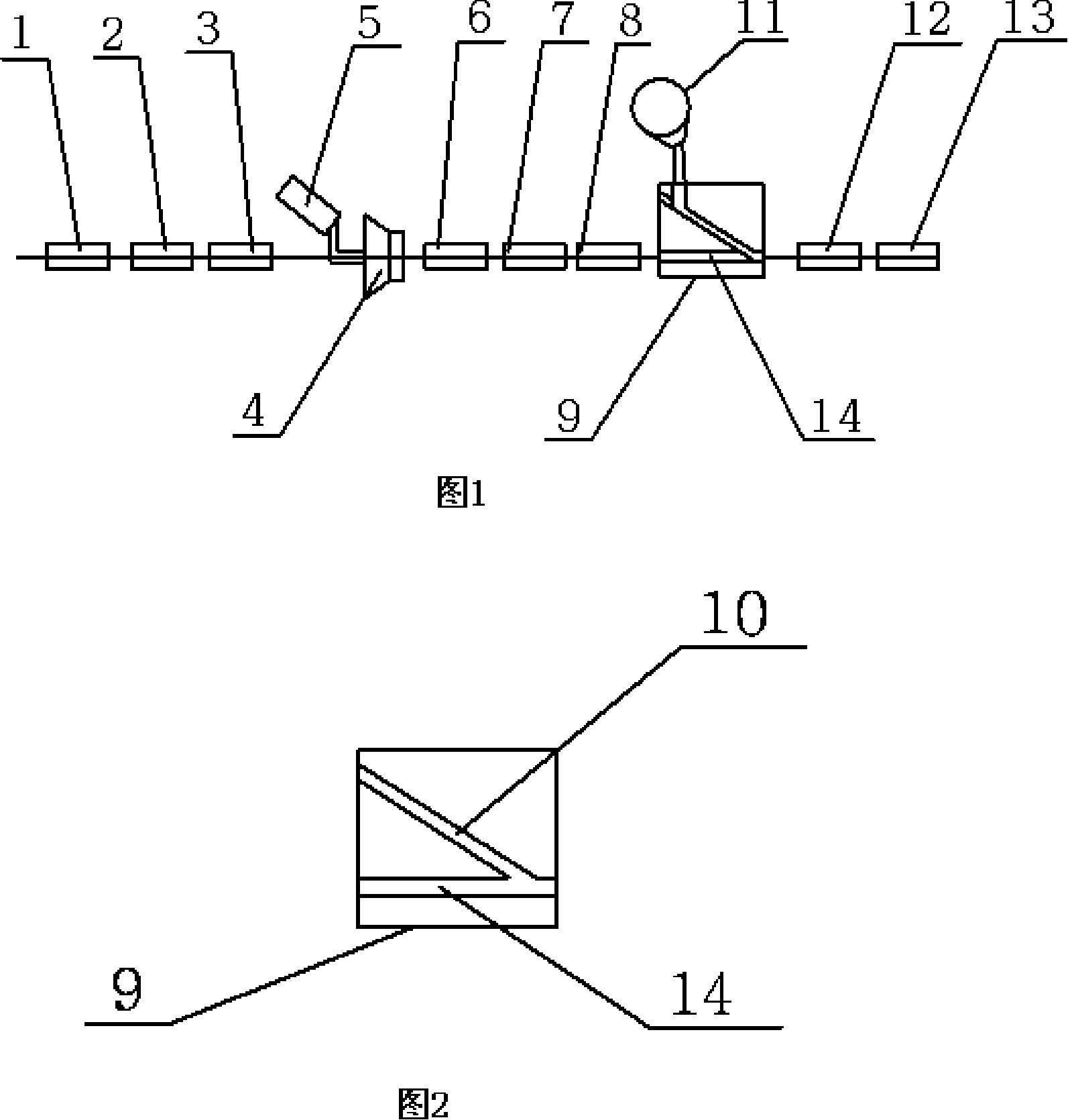

[0010] Embodiment 1 of the present invention: the processing of the present invention is as shown in Figure 1, and the present invention adopts steel strip uncoiler 1 and spot welding machine 2 of existing manufacturing process to make steel strip into steel skeleton, and steel skeleton is passed through steel storage The frame 3 is transported to the entrance of the compound head 4, and then fed by the EPDM extruder 5 and passed through the compound head 4. After the steel skeleton, dense rubber and sponge rubber are hot-pressed, the EPDM three-composite sealing strip is extruded, and the EPDM The three-composite sealing strip is subjected to high-temperature vulcanization treatment through the microwave vulcanization tank 6 and the hot air vulcanization tank 7, and then the vulcanized EPDM three-composite sealing strip is conveyed to the coating mold 9 by the tractor 8, at the upper end of the coating mold 9 A flow channel 10 is installed obliquely, and a horizontal flow chan...

Embodiment 2

[0011] Embodiment 2 of the present invention: the processing of the present invention is as shown in Figure 1, and the present invention adopts steel strip uncoiler 1 and spot welder 2 of existing manufacturing process to make steel strip into steel skeleton, and steel skeleton is passed through steel storage The frame 3 is transported to the entrance of the compound head 4, and then fed by the EPDM extruder 5 and passed through the compound head 4. After the steel skeleton, dense rubber and sponge rubber are hot-pressed, the EPDM three-composite sealing strip is extruded, and the EPDM The three-composite sealing strip is subjected to high-temperature vulcanization treatment through the microwave vulcanization tank 6 and the hot air vulcanization tank 7, and then the vulcanized EPDM three-composite sealing strip is conveyed to the coating mold 9 by the tractor 8, at the upper end of the coating mold 9 A flow channel 10 is installed obliquely, and a horizontal flow channel 14 fo...

Embodiment 3

[0012] Embodiment 3 of the present invention: the processing of the present invention is as shown in Figure 1, and the present invention adopts steel strip uncoiler 1 and spot welder 2 of existing manufacturing process to make steel strip into steel skeleton, and steel skeleton is passed through steel storage The frame 3 is transported to the entrance of the compound head 4, and then fed by the EPDM extruder 5 and passed through the compound head 4. After the steel skeleton, dense rubber and sponge rubber are hot-pressed, the EPDM three-composite sealing strip is extruded, and the EPDM The three-composite sealing strip is subjected to high-temperature vulcanization treatment through the microwave vulcanization tank 6 and the hot air vulcanization tank 7, and then the vulcanized EPDM three-composite sealing strip is conveyed to the coating mold 9 by the tractor 8, at the upper end of the coating mold 9 A flow channel 10 is installed obliquely, and a horizontal flow channel 14 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com