Processing method for resin hole plugging of rigid-flex board of ultrathin printed circuit

A soft-rigid combination board and printed circuit technology, applied in printed circuits, printed circuit manufacturing, printed circuit components, etc., can solve problems such as the inability to do resin plug hole technology, and the easy foaming of copper foil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for processing resin plug holes of an ultra-thin printed circuit-flex-rigid bonded board, comprising the following process steps:

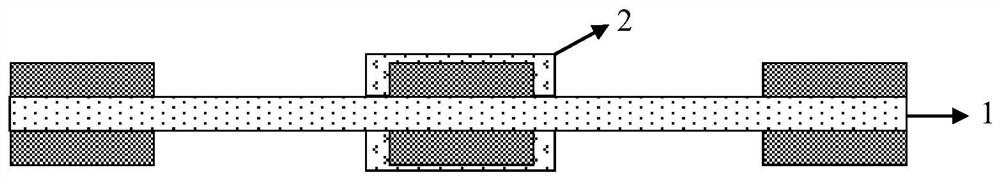

[0042] S1. To make the soft board 1 of the printed circuit soft-rigid combination board. The supplier of the soft board material is Songyang Electronics, the model is A-1005RD, the thickness of the soft board is 0.025mm, and the thickness of the copper foil is 1 / 3 ounce 0.008 mm, the supplier of cover film 2 is Taihong, the model is FHK0515, as attached figure 1 shown;

[0043] S2. Paste a layer of cover film 2 on the bent parts of the upper and lower surface layers of the flexible board 1;

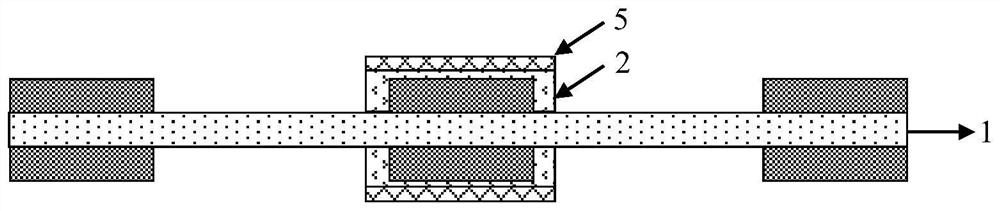

[0044] S3, as attached figure 2 As shown, prepare the PFG protective film and the pure glue adhesive, the thickness of the PFG protective film is 0.035mm, and the thickness of the pure glue is 0.025mm, and the PFG protective film and the pure glue are pre-pressed together to form a pre-pressed bonding film 5, and then Process it into the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com