Resin for novel waterborne double-component organic-inorganic hybrid coating and preparation method of resin

A two-component, modified resin technology, used in anti-corrosion coatings, coatings, etc., can solve the problems of 50-1:1 instability, and does not solve the problems of water-based two-component self-drying coatings, and achieves high fullness, resistance to The effect of excellent corrosion resistance and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

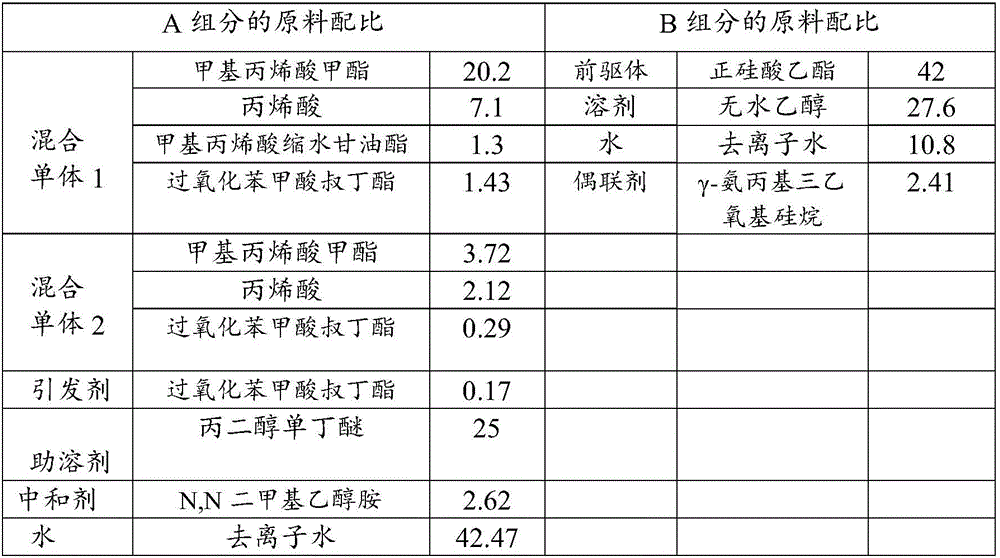

[0041] Embodiment 1 Material proportioning ratio is the following table

[0042]

[0043] The implementation method of component A is to put the formula amount of propylene glycol monobutyl ether into the reaction kettle equipped with a stirring device, a reflux condensing device, a dropping device and a temperature control device, and raise the temperature to 115°C while stirring, and add the mixed monomer dropwise 1 is dropped for about 3 hours, keep warm for 2 hours, add dropwise mixed monomer 2 for about 0.5 hours, add tert-butyl peroxybenzoate, keep warm for 4 hours. Add N,N dimethylethanolamine, disperse for 30 minutes, add 40°C deionized water, disperse at high speed for 1 hour, and filter out the material.

[0044] The preparation method of component B is to put tetraethyl orthosilicate, absolute ethanol and water in the formula ratio into a reaction kettle equipped with a stirring device, a reflux condensing device, a dropping device and a temperature control devic...

Embodiment 2

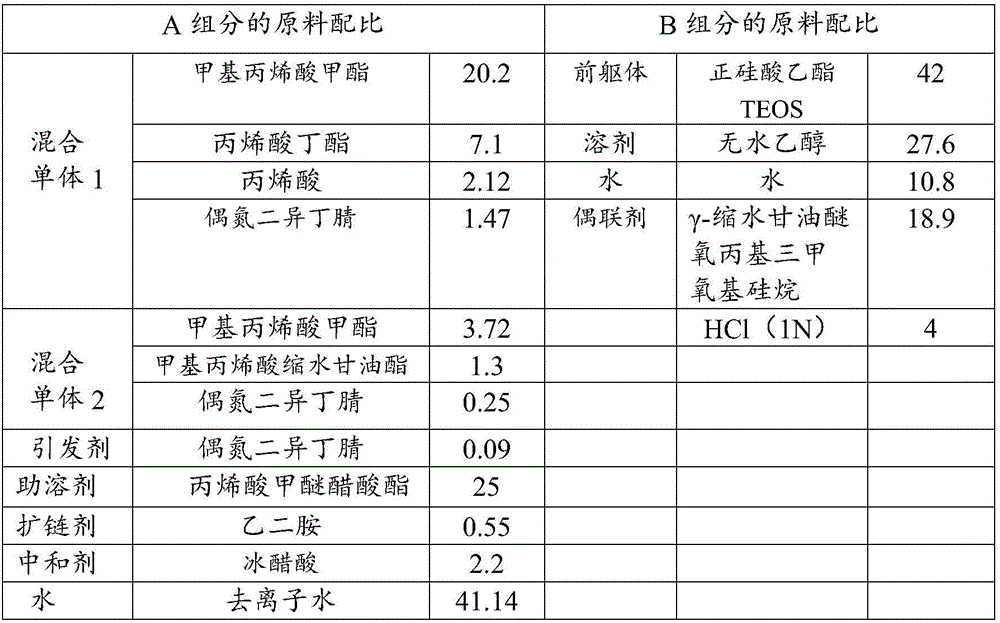

[0045] Embodiment 2 material ratio following table

[0046]

[0047] The production method of component A is to put propylene glycol methyl ether acetate into a reaction kettle equipped with a stirring device, a reflux condensing device, a dropping device and a temperature control device. While stirring, the temperature is raised to 75°C, and the mixed monomer 1 is added dropwise. After about 3 hours of dripping, keep warm for 2 hours and add the mixed monomer 2 dropwise for about 0.5 hours, then add azobisisobutyronitrile and keep warm for 4 hours. Add ethylenediamine at 70°C, disperse for 1hr, add glacial acetic acid at 60°C, disperse for 30min, add deionized water at 40°C, disperse at high speed for 1hr, filter and discharge.

[0048] The preparation method of component B is to drop methyltriethoxysilane, dehydrated alcohol, water, 1mol / L hydrochloric acid into a reaction kettle equipped with stirring device, reflux condensing device, dropping device and temperature cont...

Embodiment 3

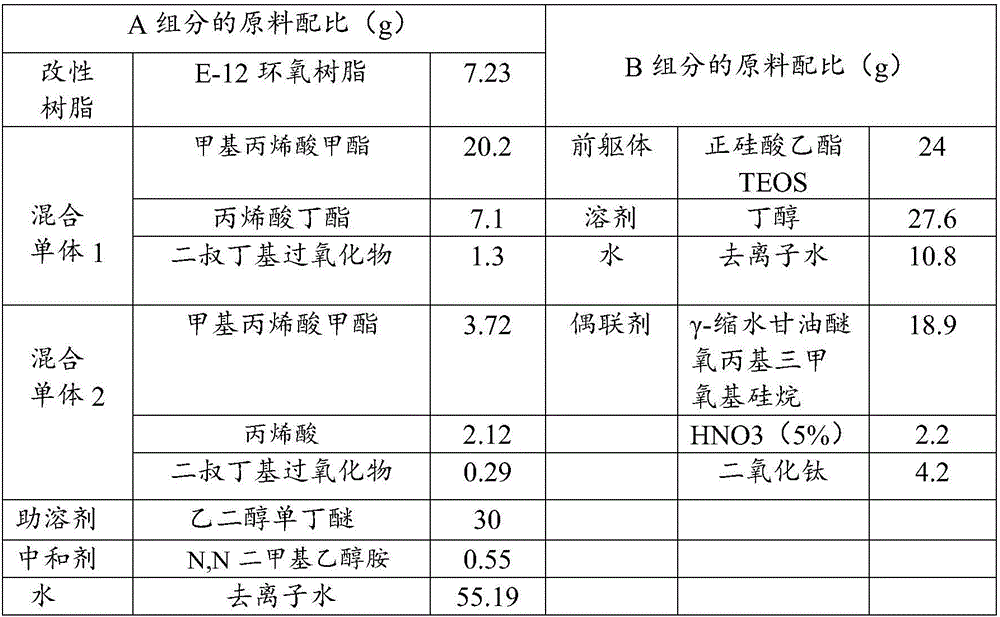

[0049] Embodiment 3 material ratio following table

[0050]

[0051] The preparation method of component A is to put E12 and ethylene glycol monobutyl ether into a reaction kettle equipped with a stirring device, a reflux condensing device, a dropping device and a temperature control device. While stirring, the temperature is raised to 145°C, and the mixture is added dropwise. Monomer 1 is dripped for about 3 hours, kept for 2 hours, and mixed monomer 2 is added dropwise for about 0.5 hours, then di-tert-butyl peroxide is added, and kept for 4 hours. Add N,N dimethylethanolamine at 80°C, disperse for 1 hr, add deionized water at 40°C, disperse at high speed for 1 hr, and filter out.

[0052] The preparation method of component B is to put TiO2, tetraethyl orthosilicate, butanol, water, and nitric acid with a mass fraction of 5% in a reaction kettle equipped with a stirring device, a reflux condensing device, a dropping device and a temperature control device, and heat up A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com