Round loom for producing inner external wall film coated water delivery flexible pipes

A technology of inner and outer walls and circular looms, which is applied in the field of hoses, can solve the problems of easy breakage, breakage, and low strength, and achieve the effects of reducing raw material consumption, prolonging service life, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

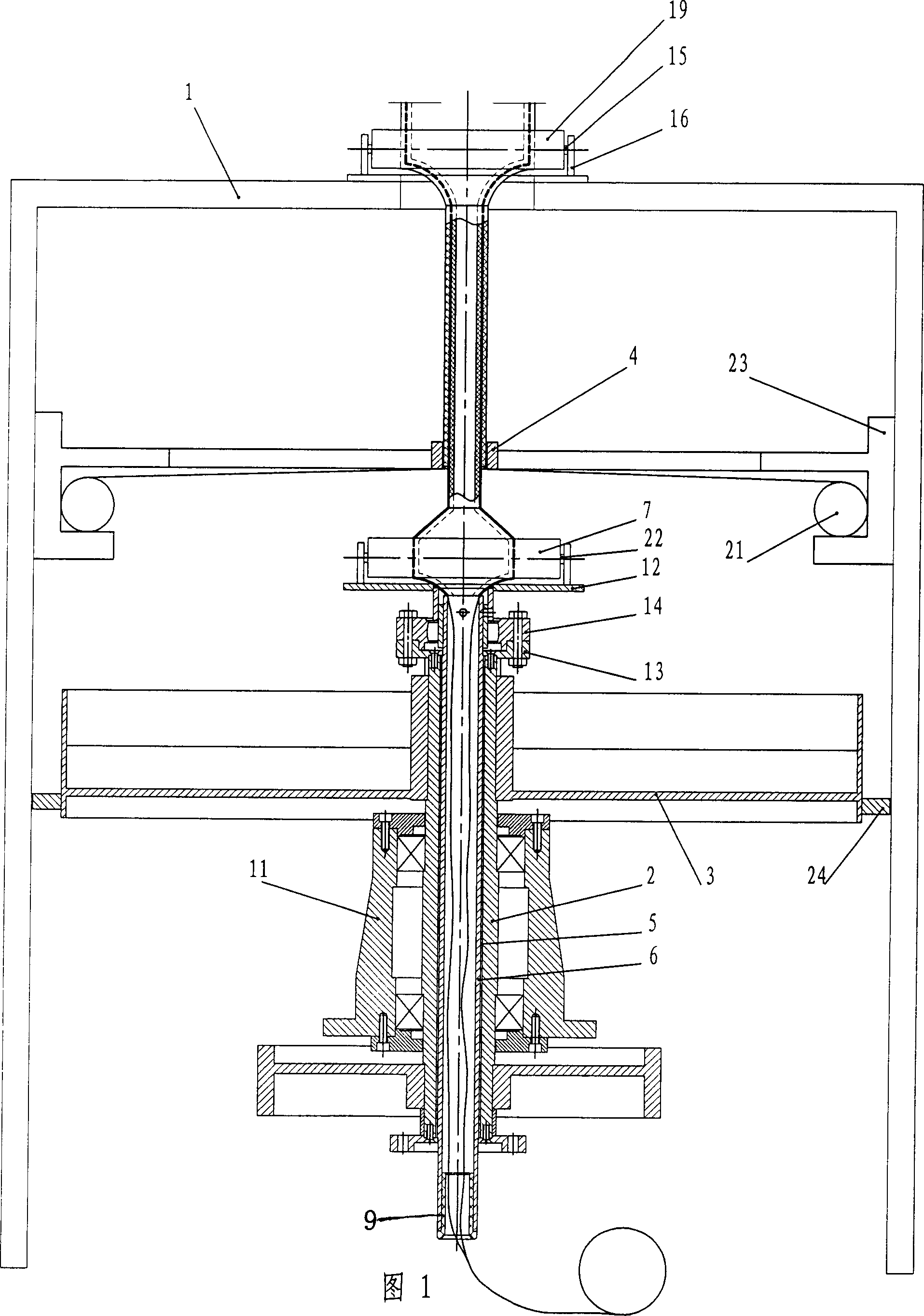

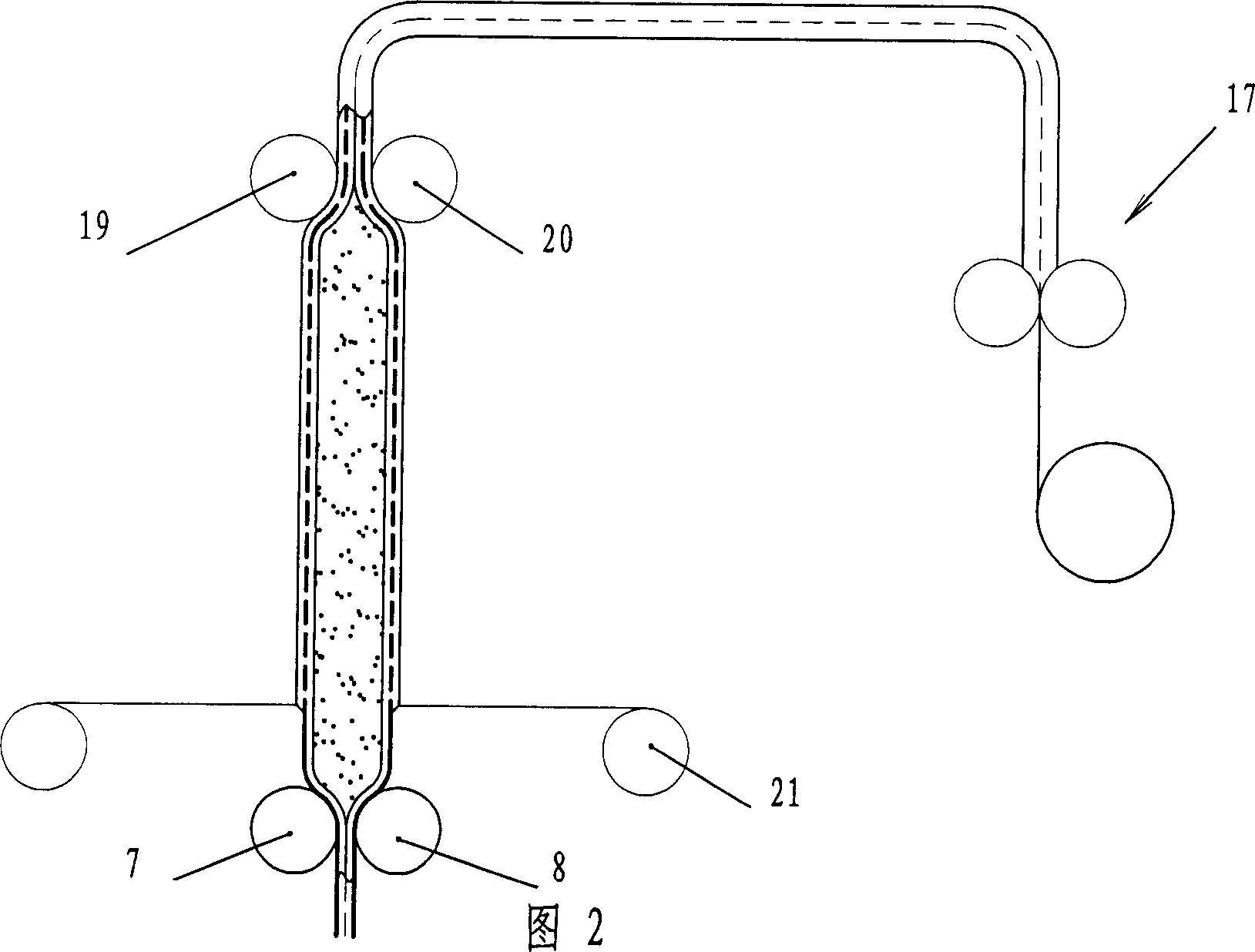

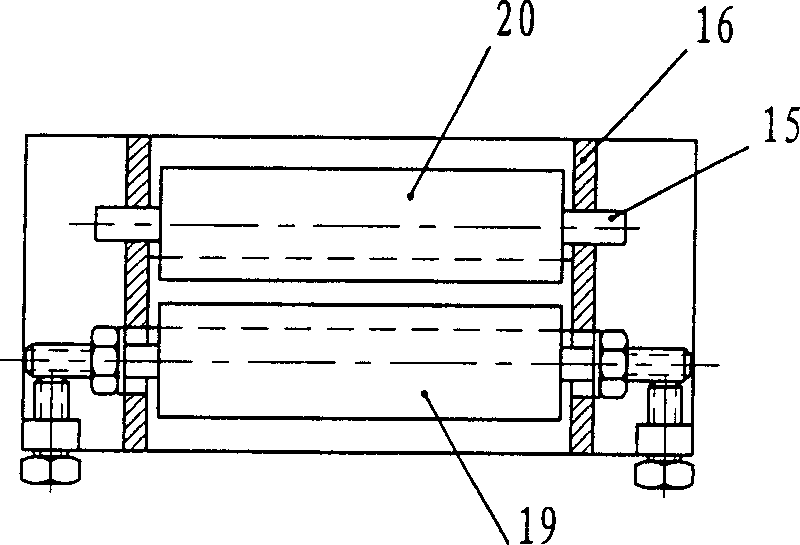

[0016] As shown in Fig. 1 and Fig. 2, the inner and outer wall film-coated water delivery hose circular loom of the present invention is transformed on the basis of the existing circular loom for producing woven bags, and it includes a frame 1, the shuttle runway 23, the outside of the shuttle runway 23 is provided with multiple groups of heald belts (not shown in the figure), each group of heald belts has 2 inner and outer heald belts, and the inner and outer 2 heald belts are with the warp, Under the staggered movement, each warp stretches to the lower end of the size ring 4 respectively, and the number of heddle belts is 8-36. The inner circle of the shuttle runway 23 is provided with a plurality of shuttles 21 and a shuttle wheel (not shown) matched with an end of the shuttle 21, and the quantity of the shuttles 21 is 4-24, and the parallels of each shuttle 21 extend respectively. to the lower end of size ring 4. A plurality of shuttle-pushing wheels are installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com