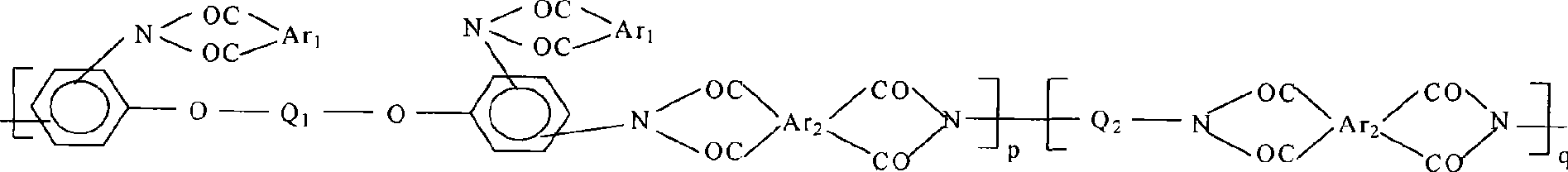

Colorless transparent aromatic polyimide film and preparation method thereof

A polyimide film and aromatic primary amine technology, which is applied in the field of preparation of colorless and transparent organic polymer films, can solve the problems that have not yet been published in literature or patent reports, and achieve excellent dimensional stability and mild reaction conditions , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

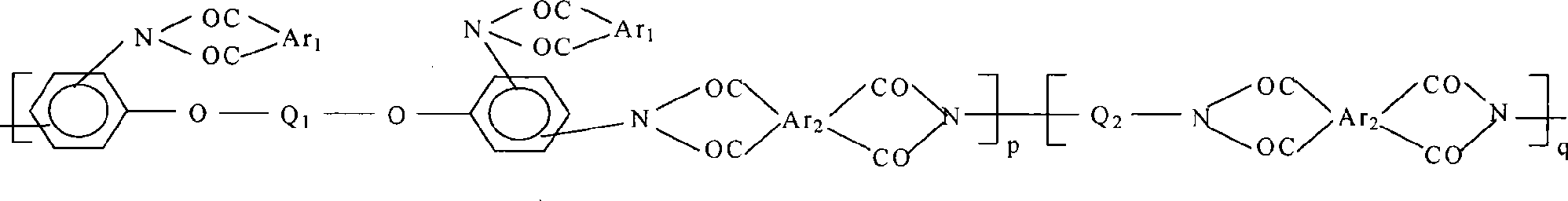

Embodiment 1

[0043]440.5 grams (1.0 moles) of 2,2-bis[4-(2,4-diaminophenoxy)phenyl]propane and 23200 milliliters of N,N-dimethylacetamide were added to the reaction kettle, at room temperature Stir and dissolve completely, cool in an ice-water bath to 0°C, add 440.0 grams (2.0 moles) of tetrafluorophthalic anhydride, stir and react within the temperature range of 0°C-35°C, and continue to react for 0.5 hours after a homogeneous solution is formed , add 400.0 grams (1.0 moles) of 4,4'-bis(4-aminophenoxy) diphenyl sulfide, stir, after completely dissolving, cool to 0°C in an ice-water bath, add 1040.0 grams (2.0 moles) of 2, 2-bis[4-(3,4-dicarboxyphenoxy)phenyl]propane dianhydride was stirred in the temperature range of 0°C-35°C, and after it was completely dissolved, the reaction was maintained for 5 hours to obtain a colorless and transparent homogeneous Viscous solution, filter, remove mechanical impurities, adjust viscosity, cast on a casting machine to form a film with a predetermined t...

Embodiment 2

[0046] 54.8 grams (0.1 mol) of 2,2-bis[4-(2,4-diaminophenoxy)phenyl]hexafluoropropane and 500 milliliters of N,N-dimethylformamide and 3000 milliliters of N- Add methyl-2-pyrrolidone into the reaction kettle, stir at room temperature, after completely dissolving, cool in an ice-water bath to 0°C, add 22.0 grams (0.1 moles) of tetrafluorophthalic anhydride and 14.8 grams (0.1 moles) of phthalic anhydride Formic anhydride, stirred and reacted within the temperature range of 0°C-35°C. After a homogeneous solution was formed, the reaction was continued for 2 hours, and 29.2 grams (0.1 moles) of 1,3-bis(4-aminophenoxy)benzene, 385.2 grams of (0.9 mol) 1,4-bis(2-trifluoromethyl-4-aminophenoxy)benzene, stirring, after completely dissolving, cooling to 0°C in an ice-water bath, adding 628.0 g (1.0 mol) 2,2- Bis[4-(3,4-dicarboxyphenoxy)phenyl]hexafluoropropane dianhydride and 31.0 grams (0.1 moles) of 3,3',4,4'-tetracarboxylic acid diphenyl ether dianhydride powder, in Stir in the tem...

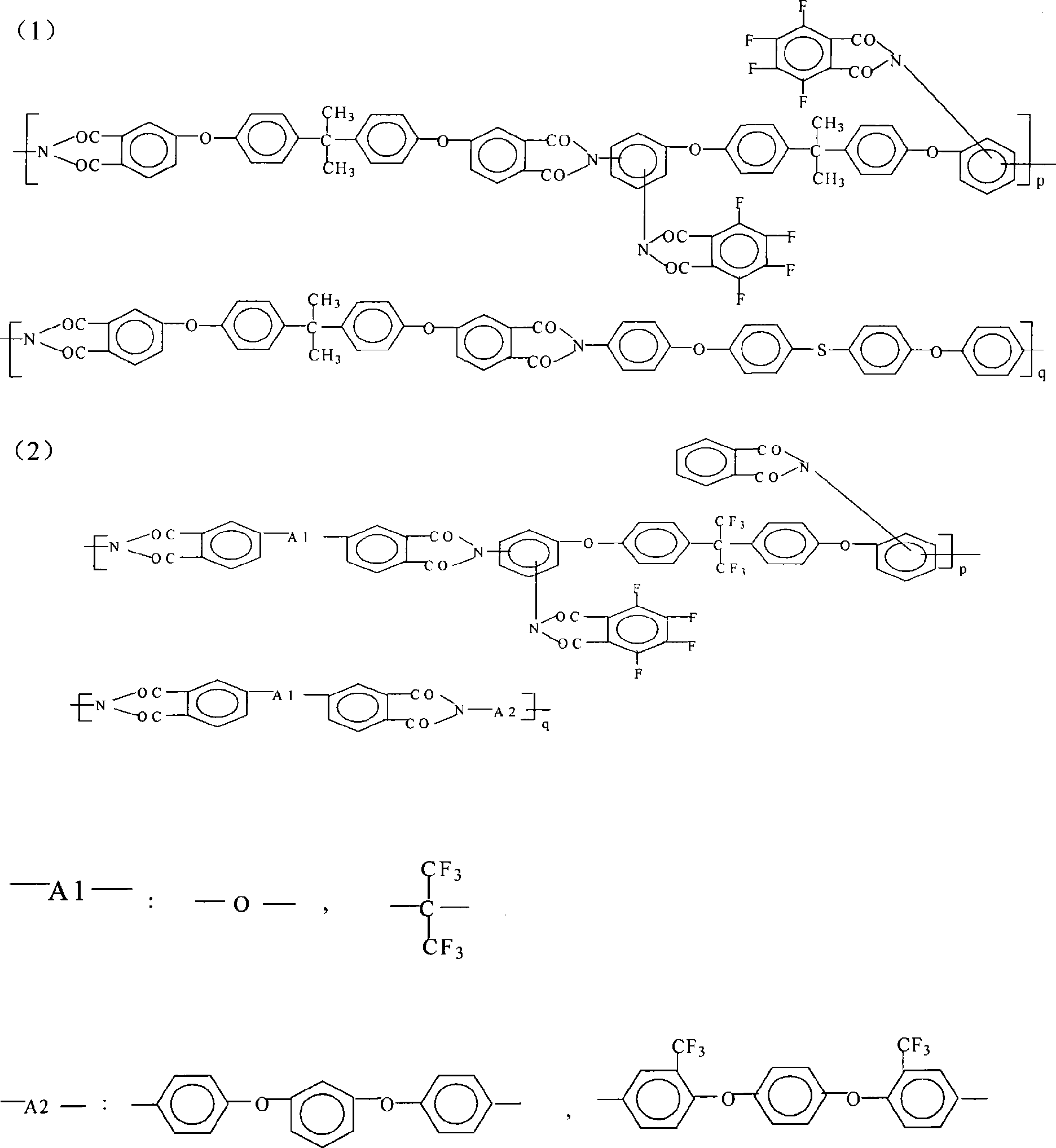

Embodiment 3

[0049] 440.5 grams (1.0 moles) of 2,2-bis[4-(2,4-diaminophenoxy)phenyl]propane and 6000 milliliters of N,N-dimethylacetamide were added to the reaction kettle, at room temperature Stir and dissolve completely, cool in an ice-water bath to 0°C, add 440.0 grams (2.0 moles) of tetrafluorophthalic anhydride, stir and react within the temperature range of 0°C-35°C, and continue to react for 0.5 hours after a homogeneous solution is formed , to get A component.

[0050] 54.8 grams (0.1 moles) of 2,2-bis[4-(2,4-diaminophenoxy)phenyl]hexafluoropropane and 4000 milliliters of N,N-dimethylacetamide were added to the reactor, Stir at room temperature, after completely dissolving, cool in an ice-water bath to 0°C, add 16.6 grams (0.1 mole) of 4-fluorophthalic anhydride and 14.8 grams (0.1 mole) of phthalic anhydride, at a temperature of 0°C-35°C The reaction was stirred within a certain range, and after a homogeneous solution was obtained, the reaction was continued for 0.5 hours to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com