Method for determining corn grain hardness

A determination method and grain technology, applied in the direction of testing material hardness, etc., can solve the problems of inability to measure the hardness of wheat, poor comparability of hardness values, and inability to fully apply hardness testing, etc., and achieve fast detection speed, convenient operation, and high hardness resolution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

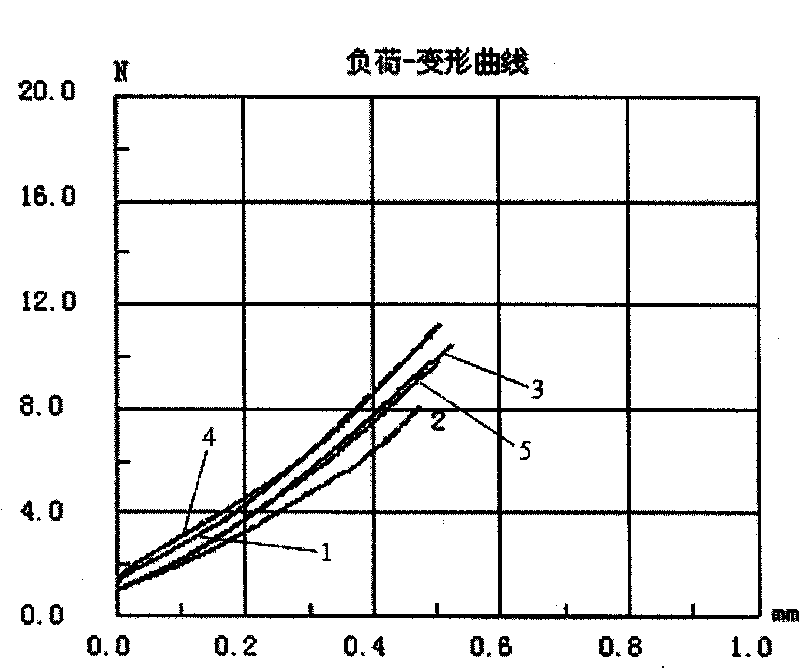

[0034] Embodiment 1: the mensuration of corn hardness

[0035] (1) Preparation before grain measurement: sample making (taking Gansu Jinsui No. 4 corn kernels as an example)

[0036] Grind the corn kernels with No. 0 or No. 1 sandpaper or a fine-grained file to expose the corresponding parts to be tested to form the surface to be tested, and smooth the other side of the corn kernels to form a base surface. When grinding, try to make the surface to be tested The measuring surface and the base surface are kept parallel. The base surface should be ground as large as possible to ensure the stability of the sample under pressure; the surface to be tested should be ground smaller, as long as the part to be tested can be exposed. The part to be tested has sufficient thickness. On the polished surface to be tested, the color of the embryo of Jinsui No. 4 corn was slightly blue, the horny endosperm was golden yellow, and the floury endosperm was white. The test will measure the hard...

Embodiment 2

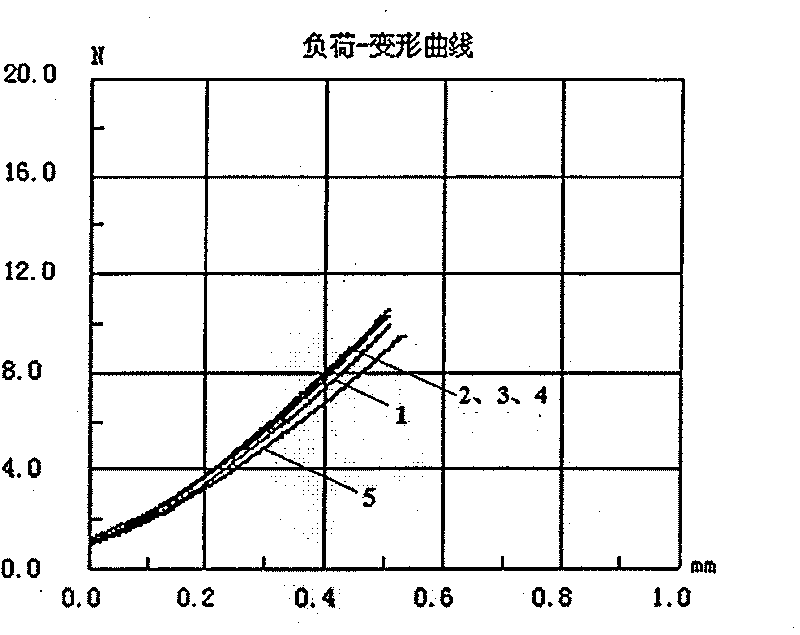

[0057] Embodiment 2: Determination of Hardness of Xihan No. 1 Wheat

[0058] (1) Preparation before grain determination:

[0059] Take 20 grains of wheat with a moisture content of 13.01%, and one side with grooves (referring to the ventral groove of wheat) is ground as the base surface, and the other side (the back side of the wheat grains) is lightly ground as the surface to be tested.

[0060] (2) Selection of testing machine: (same as Example 1)

[0061] (3) Selection and clamping of steel needles: (same as Example 1)

[0062] (4) Determination process:

[0063] Before the start of the test, the insertion depth of the steel needle was set at 0.5mm, and the sample gauge length, sample diameter, and loading speed were the same as in Example 1.

[0064] (5) Determination of hardness:

[0065] Measure the hardness of 20 polished wheat grains, and after taking the average value, the hardness value of the back side of the wheat grains is 28.36. The corresponding SKCS hardne...

Embodiment 3

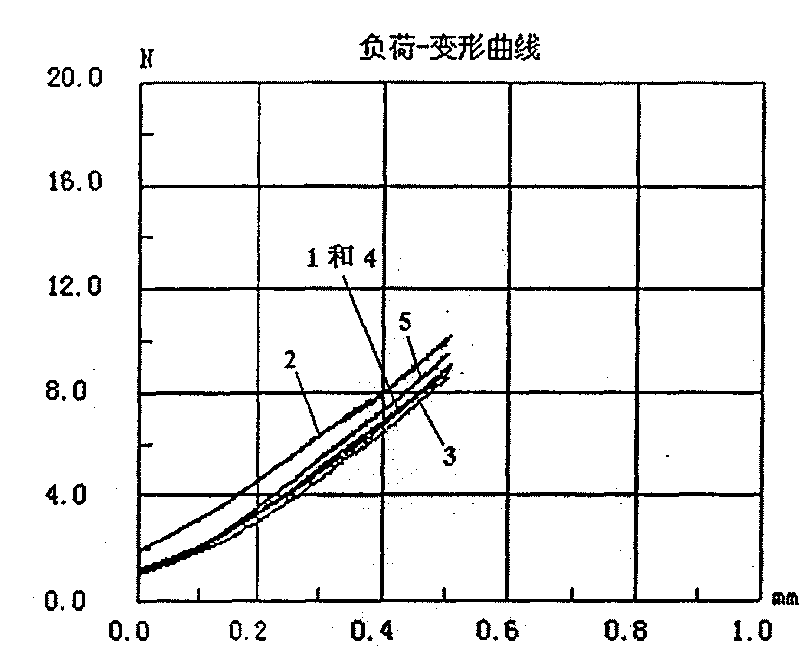

[0071] Embodiment 3: Dingpi No. 1 pea hardness determination (method and steps are the same as above)

[0072] (1) Preparation before grain measurement: (sample preparation)

[0073] Take 20 Dingpia No. 1 peas with a moisture content of 13.2%, and grind out two parallel surfaces one by one as the base surface and the surface to be tested. Note that the surface to be tested should not be perpendicular to the contact surface between the two petals of the pea. Avoid the needle tip sticking to the junction seam of the two petals of the pea, causing measurement errors.

[0074] Step (2)-(4) is identical with example 2

[0075] (5) Determination of hardness:

[0076] After taking the average value of the measurement results of 20 peas, the hardness value of the peas is obtained: 29.50.

[0077] image 3 It is the measurement curve of 5 peas among them, and Table 5 is the corresponding measurement result.

[0078] Table 5 Determination results of pea hardness of Dingying No. 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com