Self-propelled shelled corn and corncob classification harvester

A self-propelled technology for corn kernels, applied to harvesters, agricultural machinery and tools, agriculture, etc., can solve the problems of inability to realize corn kernel shaft sorting and harvesting, and achieve the effects of shortening harvest time, improving production efficiency, and facilitating transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

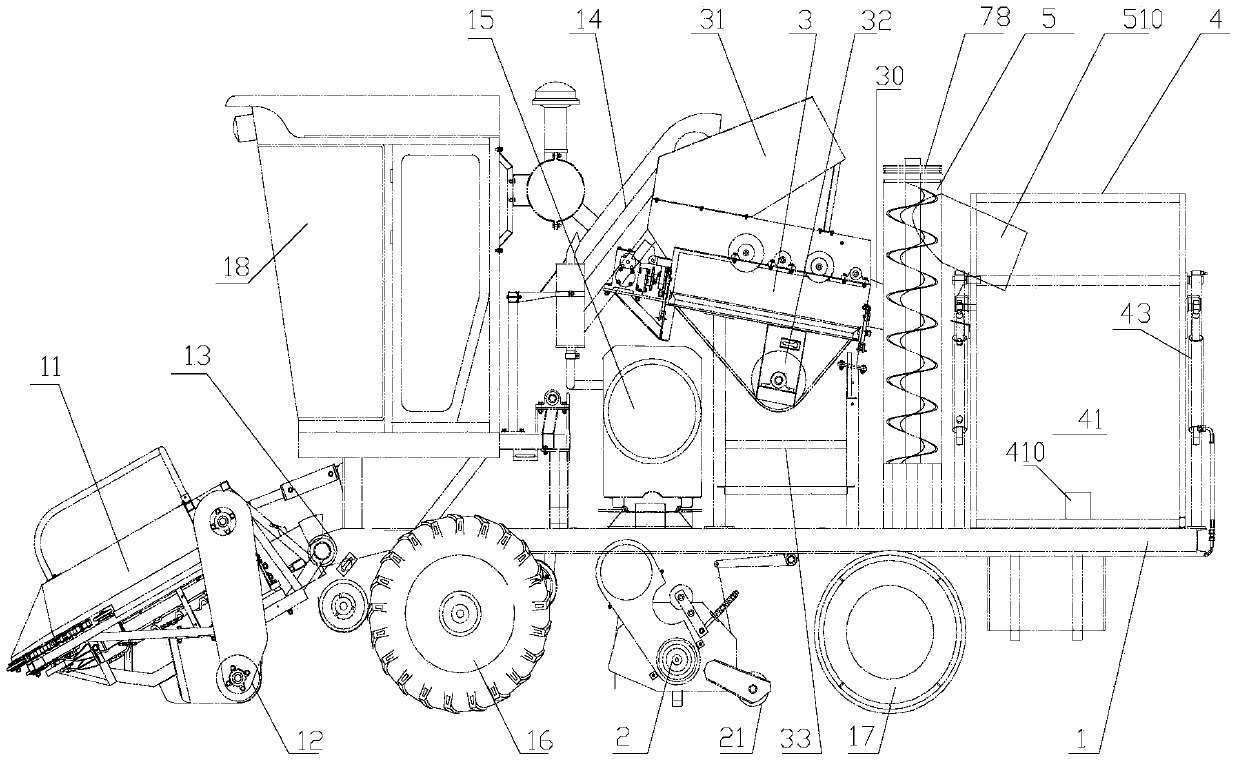

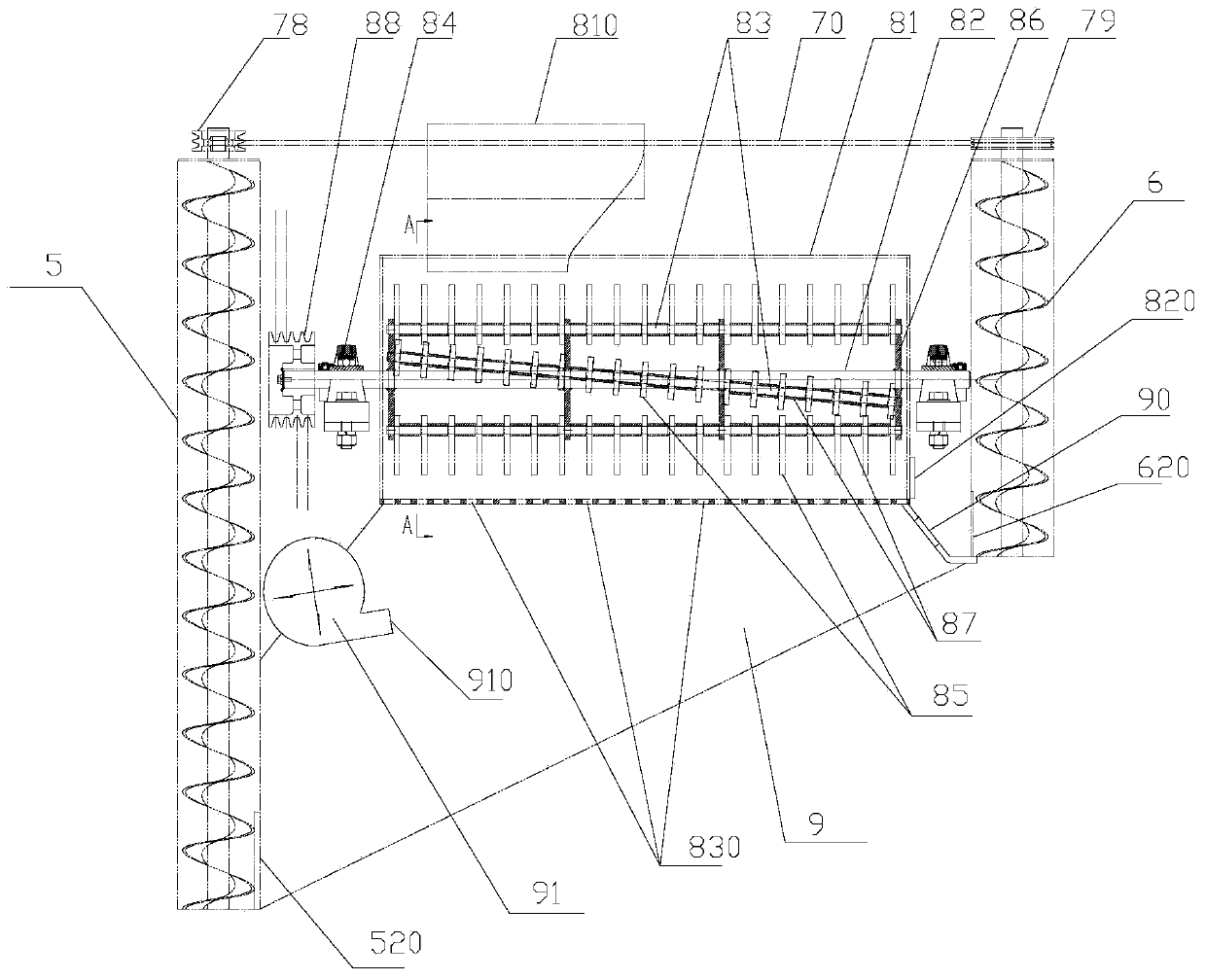

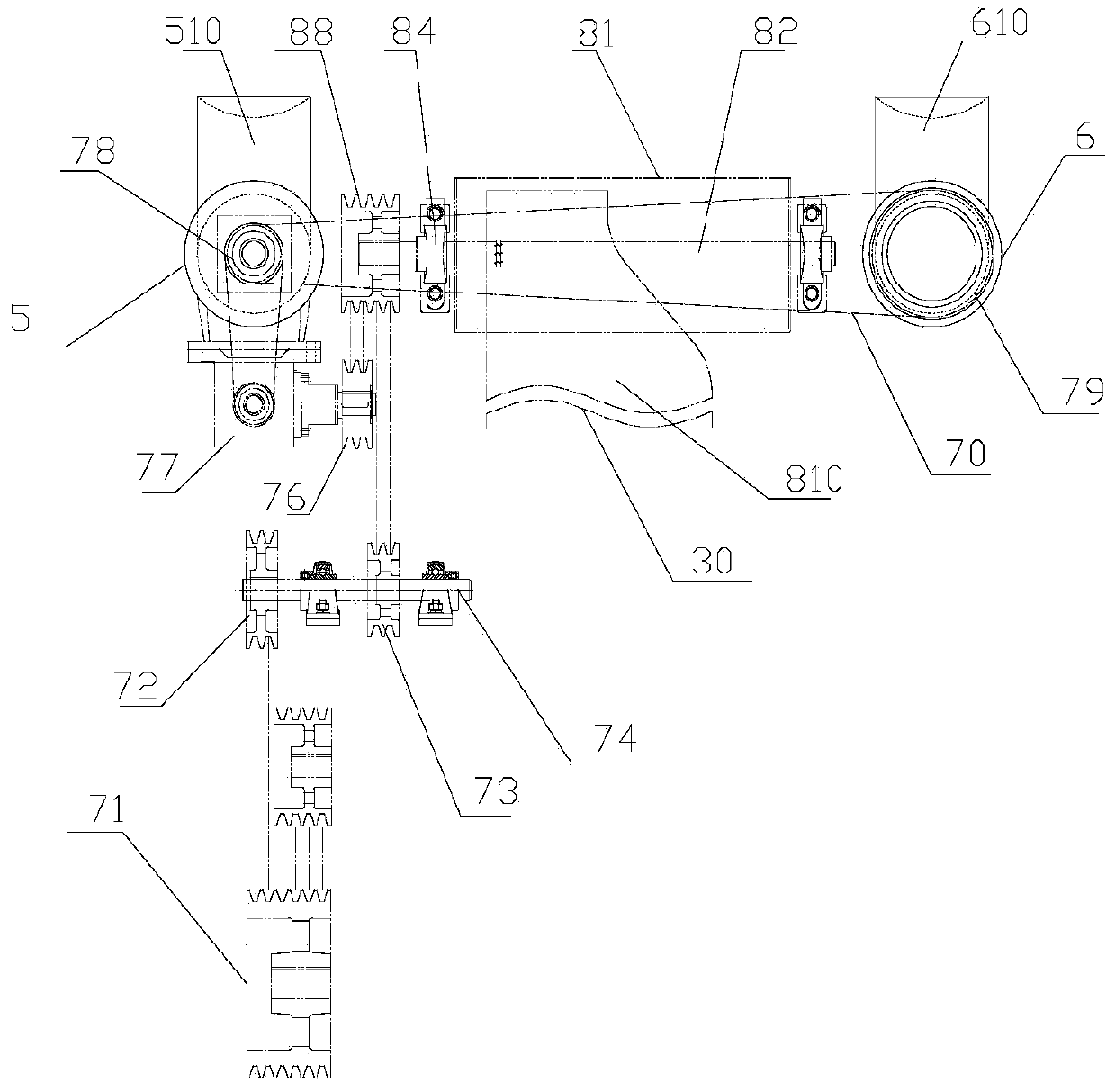

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] figure 1Schematically shows the side view structure of the preferred embodiment of the present invention, as shown in the figure, the main components of the preferred embodiment of the present invention include a chassis 1, a harvesting platform 11, a front field returning machine 12, a small elevator 13, Large elevator 14, diesel engine 15, driving wheel 16, steering wheel 17, driver's cab 18, center return field machine 2, peeling machine 3, granary 4, corn grain auger 5, corn shaft auger 6, thresher, etc. . Those skilled in the art should know that this preferred embodiment also includes safety protection structures, circuit systems, and various types of transmission mechanisms, such as the hydraulic pressure between the diesel engine 15 and the front returning machine 12 and the middle returning machine 2. Transmission me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com