Mid-depth layer oil reservoir double-horizontal-well equal-temperature-difference forced steam circulation preheating method

A dual-horizontal well, cyclic preheating technology, applied in earthmoving, wellbore/well components, production fluids, etc., can solve the problem of difficulty in realizing cyclic preheating in medium and deep heavy oil reservoirs, and overcome the problems of cyclic preheating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

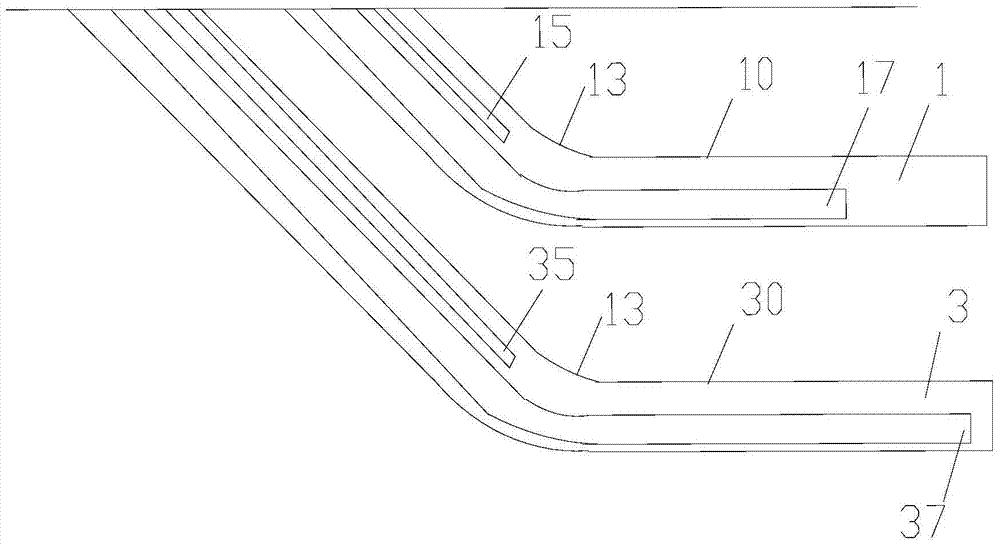

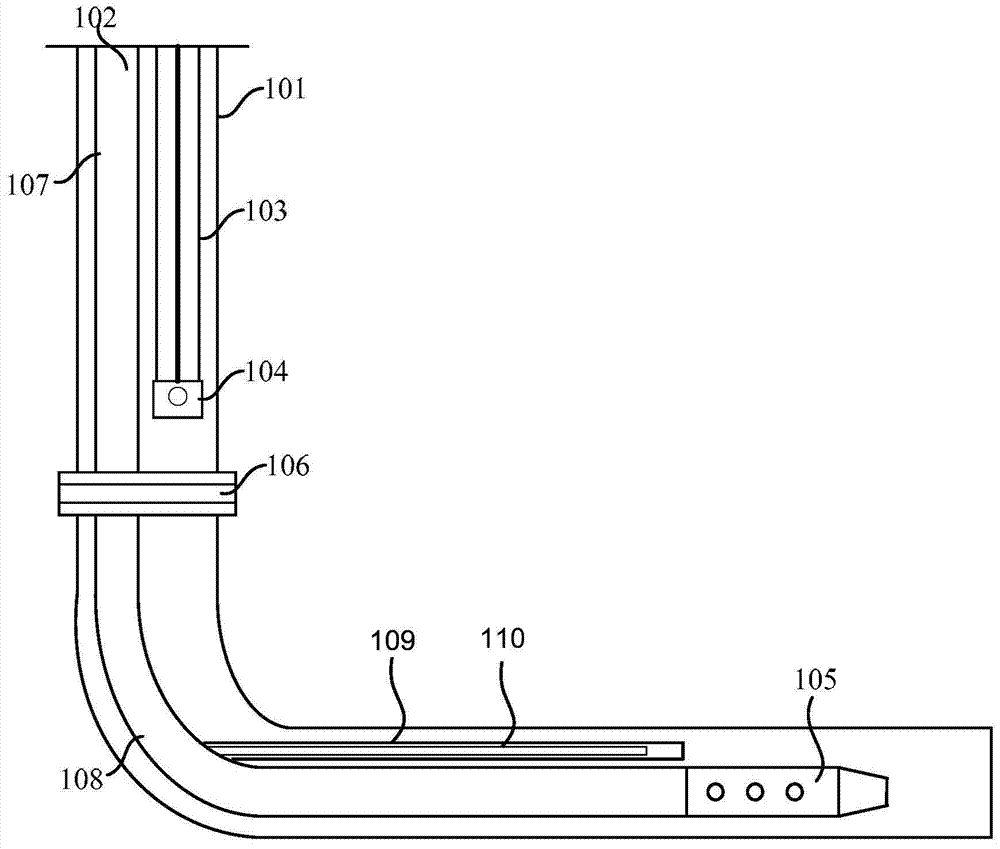

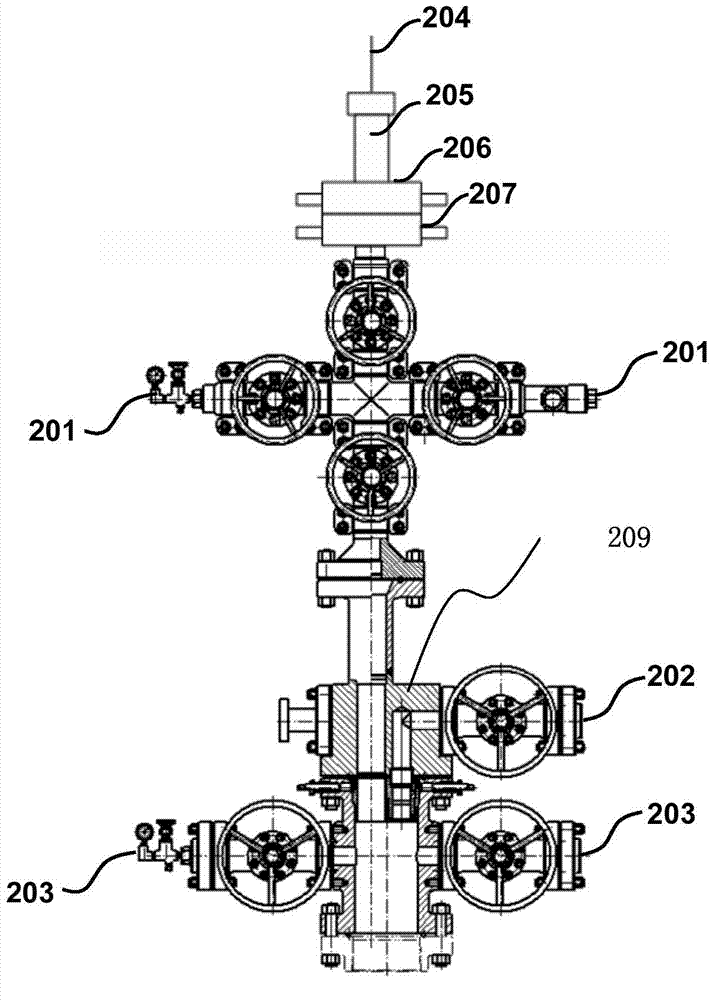

[0082] Example 1: A sandstone group oil layer in a certain oil reservoir is a sandstone group oil reservoir with a buried depth of 955 meters. The viscosity of degassed crude oil at 50°C is 53450-72340mPa.s, and the thickness of the oil layer is 15 meters. At the end of the vertical well steam huff and puff, Two pairs of horizontal well groups are deployed in the reservoir area, including 2 horizontal steam injection wells, 2 horizontal production wells, and 1 horizontal observation well. The direction of the horizontal wells is basically parallel to the structural line, and the distance between the upper and lower horizontal wells is 5 meters. According to the geological characteristics and crude oil properties of the reservoir, a cyclic preheating test of a double horizontal well pair was carried out.

[0083] The average thickness of the oil layer is greater than 15 meters, and the porosity, permeability, and vertical permeability to horizontal permeability ratio are greate...

example 2

[0088] Example 2: The Guantao Formation oil layer in an oilfield is a medium-deep ultra-heavy oil reservoir with a buried depth of 680 meters. The viscosity of degassed crude oil at 50°C is 147,500-485,400 mPa.s, and the thickness of the oil layer is 80 meters. Before the present invention, the reservoir adopts a double horizontal well combination method, and its production process is divided into two stages of huff and puff and huff and puff preheating. In the huff and puff stage, the lower horizontal well huffs and puffs for four cycles. Two cycles. Periodic oil production and oil-steam ratio are both declining, and the recovery degree is 18%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com