Metal phosphorus compound for preparing biodiesel and method for preparing biodiesel using the same

A metal phosphide, biodiesel technology, applied in chemical instruments and methods, physical/chemical process catalysts, biofuels, etc., can solve the problems of inability to maintain liquid state, catalyst inactivation, etc., and achieve long-lasting activity and high hydrotreating activity. , high active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

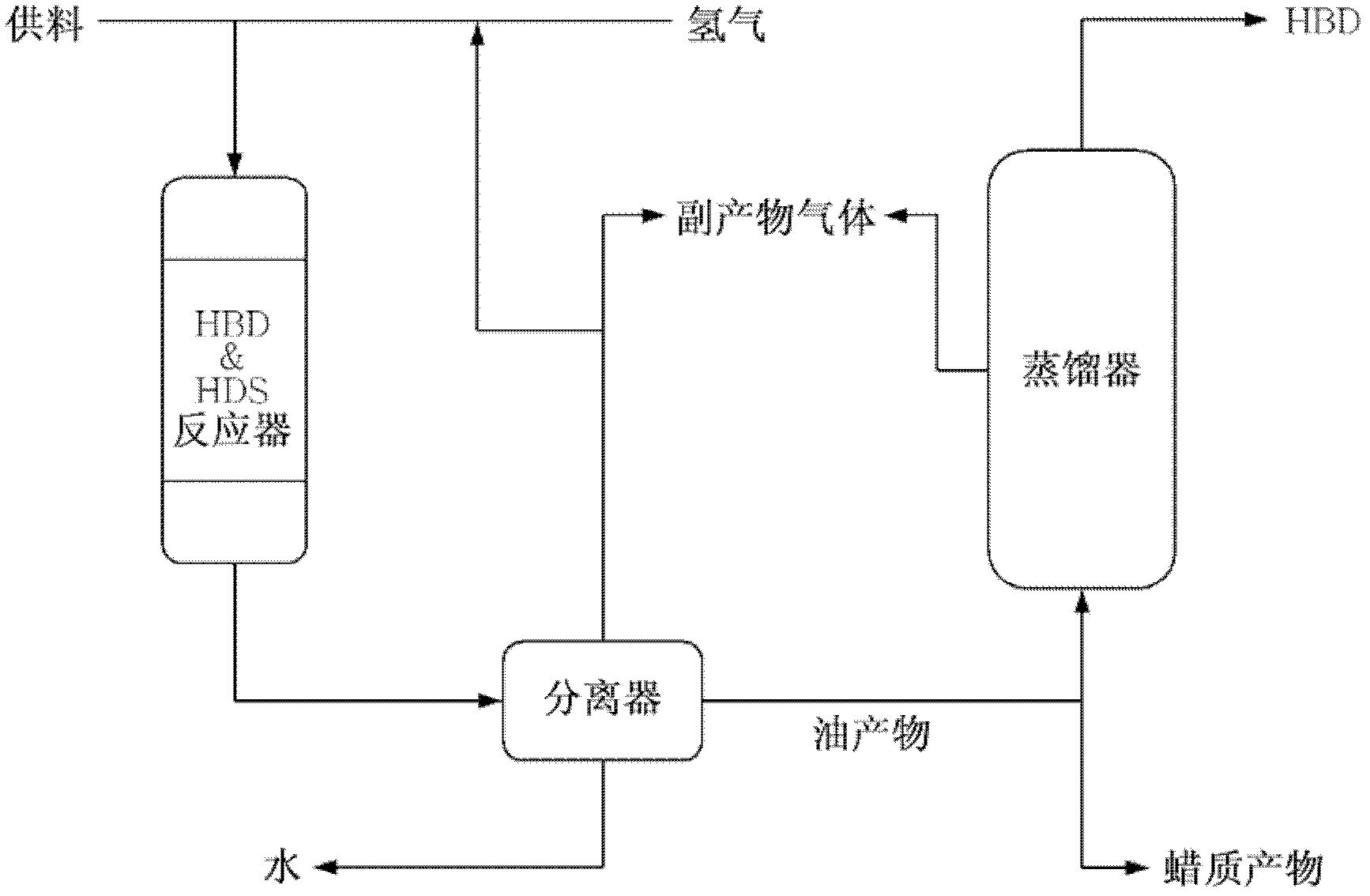

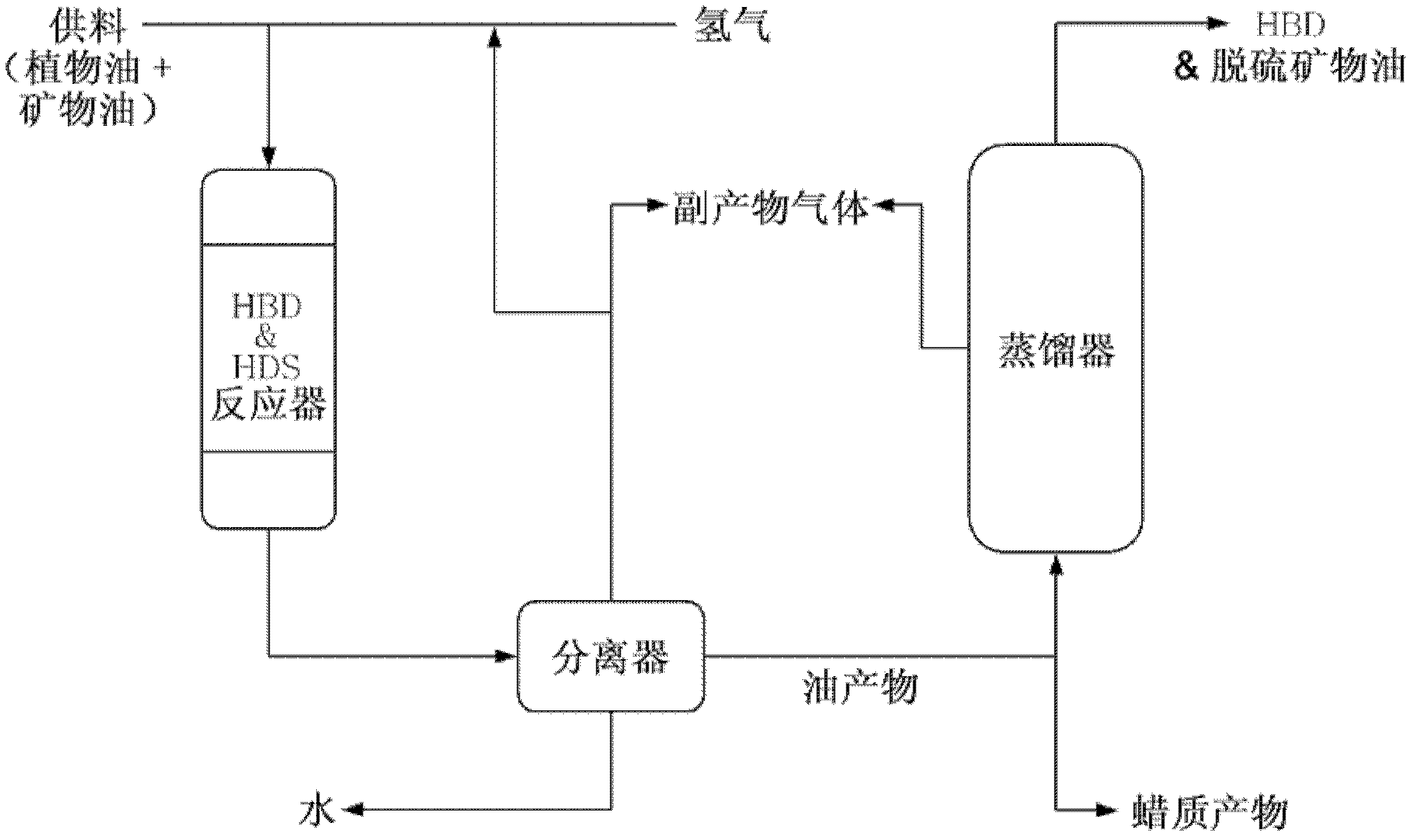

[0060] The HBD production process may include a series of steps: pretreatment of the feedstock by hydrotreating, hydrodeoxygenation followed by separation of unreacted hydrogen, and cooling and separation of produced hydrocarbons. Thus, one or two steps can be added or omitted depending on the intended goal.

[0061] The method for preparing HBD using 100% vegetable oil as feedstock is as figure 1 shown, but the present invention is not limited thereto.

[0062] A process for the preparation of HBD using a mixture of vegetable oil and hydrocarbons as feedstock such as figure 2 shown. This method differs from the method using 100% vegetable oil in that a fractionator is provided for the separation of hydrocarbons.

[0063] A mixture of vegetable oil and 1% DMDS (as a feed) can be fed to the HBD reactor simultaneously with hydrogen to hydrotreat them. The reaction mixture thus obtained can be distilled using a stripper and fractionated according to boiling point, whereby on...

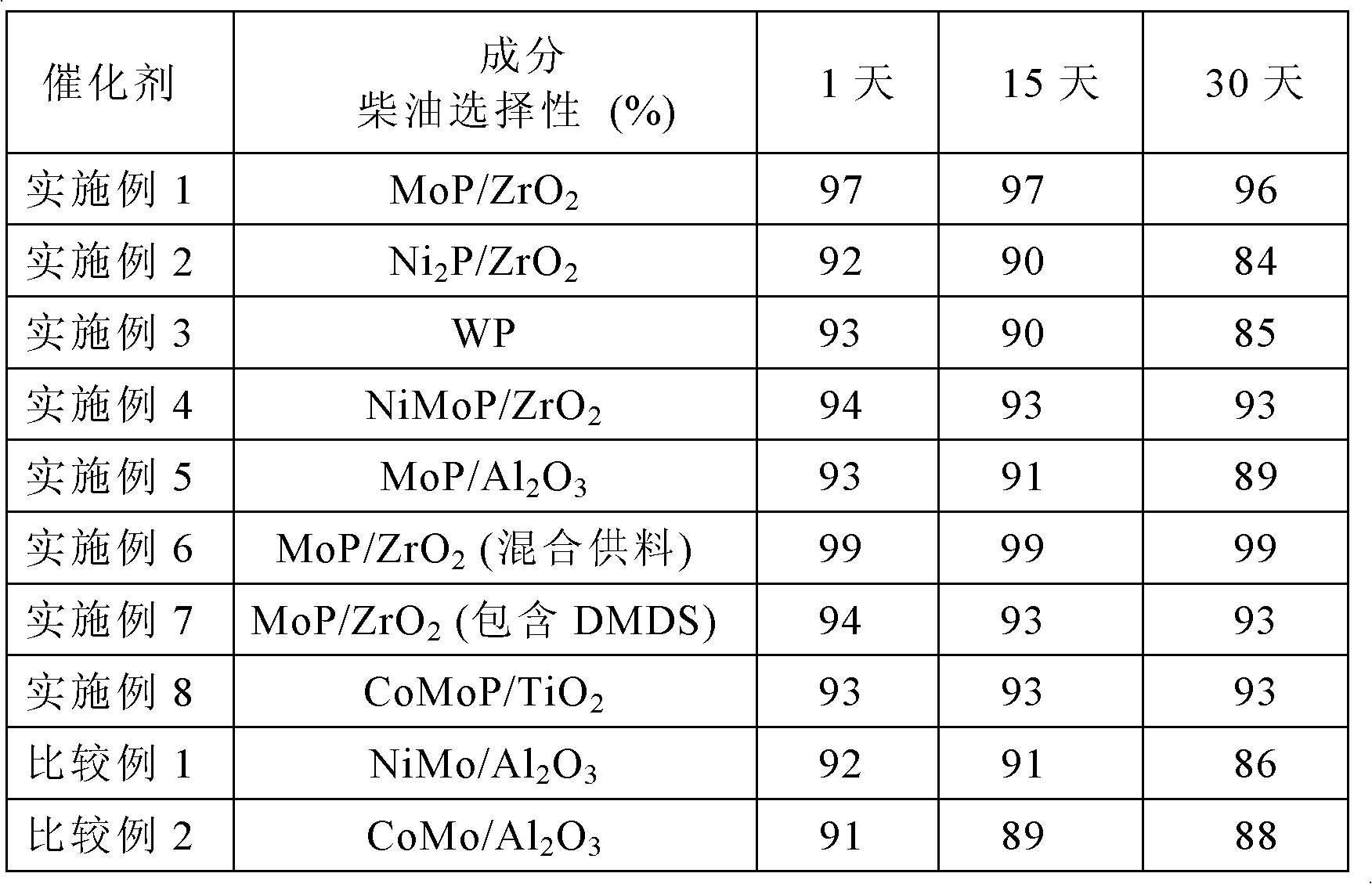

Embodiment 1

[0065] Example 1: MoP / ZrO 2 Catalyst preparation

[0066] Using ZrO with a diameter of 1mm 2 Support, a catalyst consisting of about 5% by weight Mo and about 3% by weight P was prepared.

[0067] Ammonium heptamolybdate tetrahydrate (hereinafter referred to as AHM) was used as a precursor of Mo, and ammonium phosphate (hereinafter referred to as AP) was used as a precursor of P.

[0068] AP and AHM were dissolved in distilled water and loaded on ZrO 2 support, dried at 150°C for 2 hours, and continued to calcine at 500°C for 2 hours, thus preparing MoP / ZrO 2 .

[0069] In addition to using AHM as a precursor of Mo, molybdenum acetate, molybdenum chloride, molybdenum hexacarbonyl, phosphomolybdic acid, molybdic acid, etc. may be used, but the present invention is not limited thereto. Also, precursors of P are not limited to AP, and examples thereof may include phosphorous acid, red phosphorus, yellow phosphorus, and the like.

[0070] Afterwards, 6 cc of the cataly...

Embodiment 2

[0072] Example 2: Ni 2 P / ZrO 2 Catalyst preparation

[0073] Using ZrO with a diameter of 1mm 2 Support, a catalyst consisting of about 6% by weight Ni and about 3% by weight P was prepared. Nickel nitrate (hereinafter referred to as NN) was used as a precursor of Ni, and ammonium phosphate (hereinafter referred to as AP) was used as a precursor of P.

[0074] Not only Ni metal can be provided in the form of NN, but also various precursors such as nickel acetate, nickel acetylacetonate, nickel chloride, nickel hydroxide, nickel oxalate, etc. can be used.

[0075] Ni was prepared by the following steps 2 P / ZrO 2 catalyst.

[0076] First, NN and AP were dissolved in distilled water and loaded on ZrO 2 supported, dried at 150°C for 2 hours, and continuously calcined at 500°C for 2 hours, thus preparing Ni 2 P / ZrO 2 .

[0077] Pretreatment and reaction were carried out under the same conditions as in Example 1, and analysis was carried out according to Example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com