Post-treatment method of supported alumina catalyst and obtained catalyst

A catalyst and alumina technology, applied in the direction of heterogeneous catalyst chemical elements, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., to achieve improved hydrotreating activity, improved dispersion performance, and surface The effect of property improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

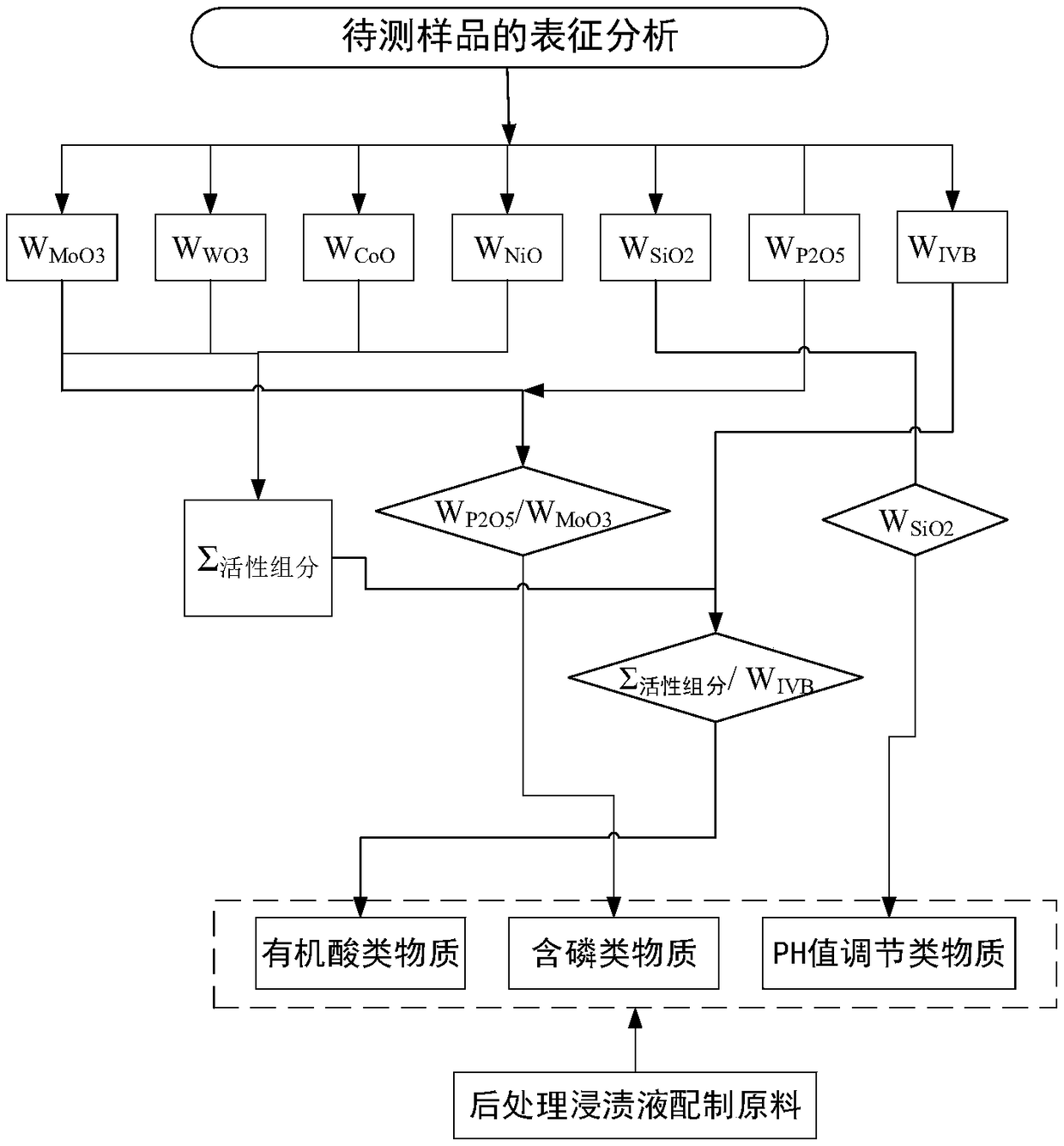

Method used

Image

Examples

Embodiment 1

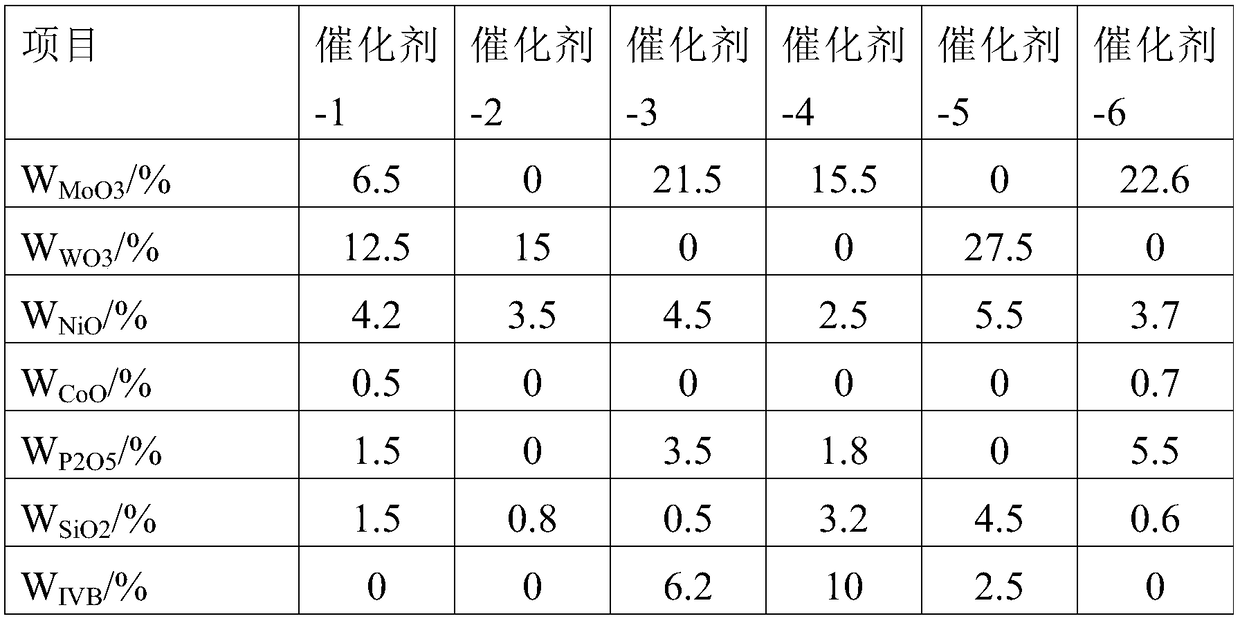

[0059] The component characterization of six kinds of hydrogenation catalysts based on alumina carrier was carried out. The characterization method was the qualitative and semi-quantitative analysis of elements by XRF analysis. The spectrometer used was the Japanese Rigaku RIX-3000 spectrometer. WMoO3 Indicates the content of molybdenum trioxide based on the total mass of the hydrogenation catalyst, and other items have similar meanings.

[0060] Table 1 Characterization data of six kinds of hydrogenation catalysts based on alumina carrier

[0061]

Embodiment 2

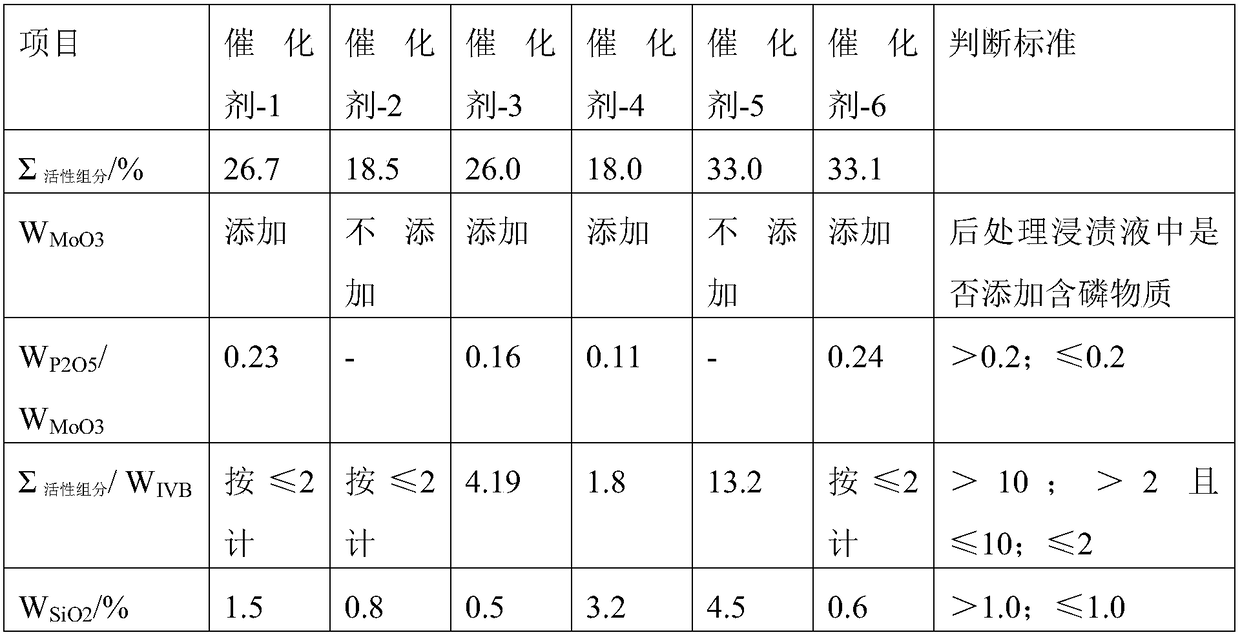

[0063] The analysis results of the six catalysts were counted and analyzed, and the specific results are shown in Table 2.

[0064] Table 2 Analysis data of 6 kinds of hydrogenation catalysts based on alumina support

[0065]

[0066] Note: when W MoO3 When the value of is 0, there is no need to add phosphorus-containing substances in the post-treatment impregnation solution; IVB When the value of is 0, the ∑ 活性组分 / W IVB The value of is less than or equal to 2.

Embodiment 3

[0068] Catalyst-1 post-treatment impregnation solution preparation, according to the analysis and statistical results of Example 1 and Example 2, citric acid and ethylenediaminetetraacetic acid are selected as organic acids to be added in the post-treatment impregnation solution, and the pH regulator is ammonia water , wherein the mass ratio of citric acid to ethylenediaminetetraacetic acid is 2:1, according to the preparation principle of post-treatment impregnating solution, the addition amount of organic acid is 1.2 times of the active component (that is, the total mass of the supported alumina catalyst is Standard, the addition amount of organic acid is 32.04wt%) Adopt the mode of equal volume impregnation to carry out impregnation. The water absorption rate of Catalyst-1 was determined to be 45.5%, and the concentration of the post-treatment impregnation solution was calculated to be 0.0989 g / ml, and the pH of the post-treatment impregnation solution was adjusted to 4.0 wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com