Asymmetric bolt-mesh-cable combination support method for special-shaped mining roadway in large dip angle coal seam

A technology of mining roadway and large inclination angle, applied in mining equipment, earthwork drilling, installation of bolts, etc., can solve the problems of difficult maintenance, strong drumming, deformation of surrounding rock of roadway, etc., to solve the problem of particularly serious deformation and reduce the number of repairs. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

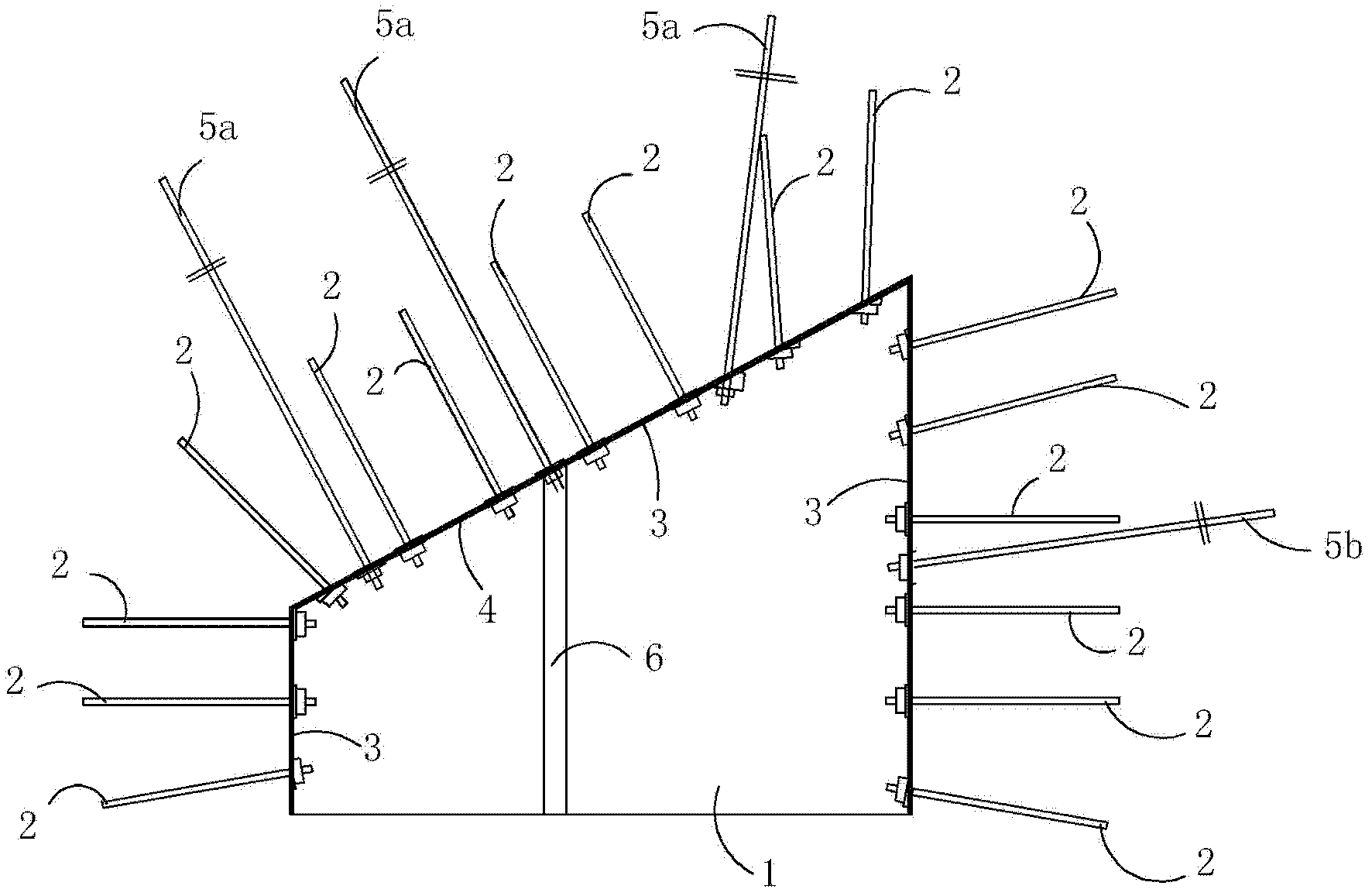

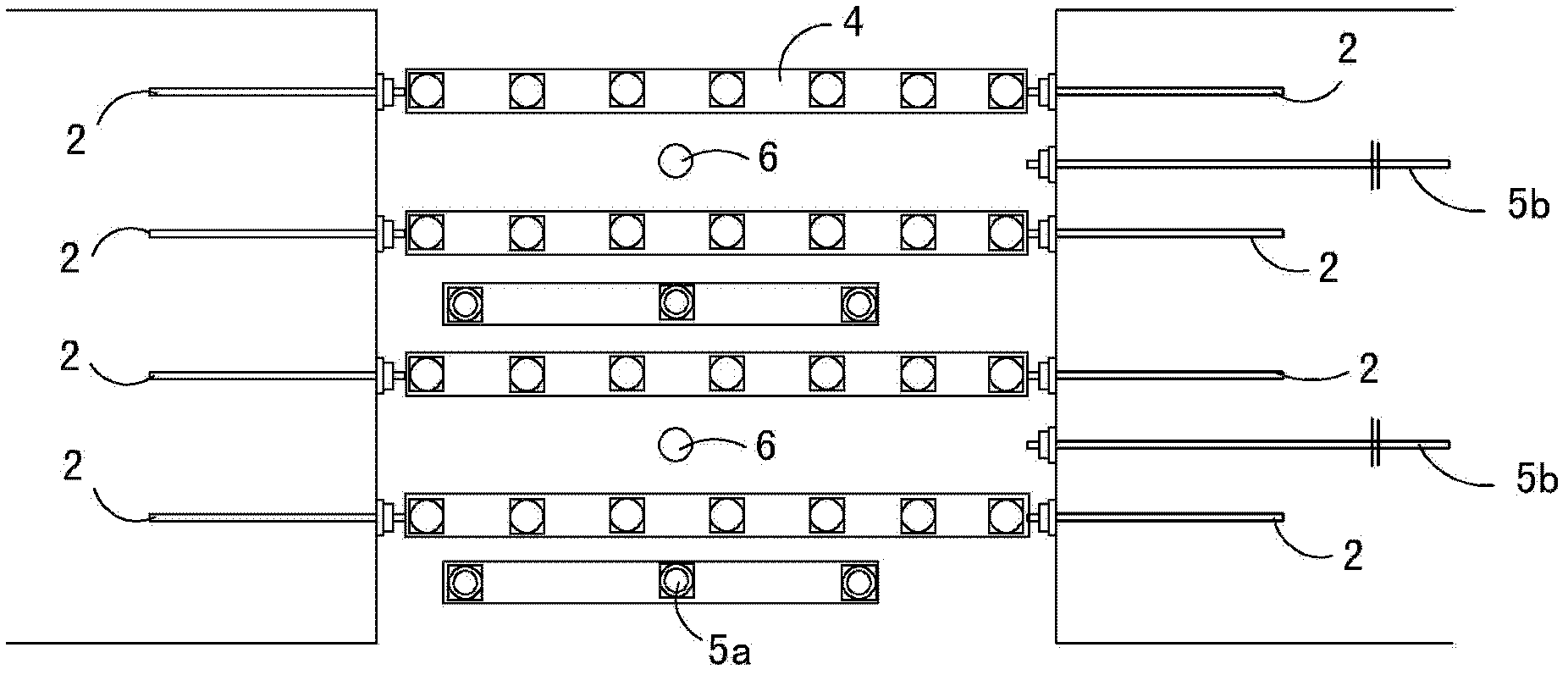

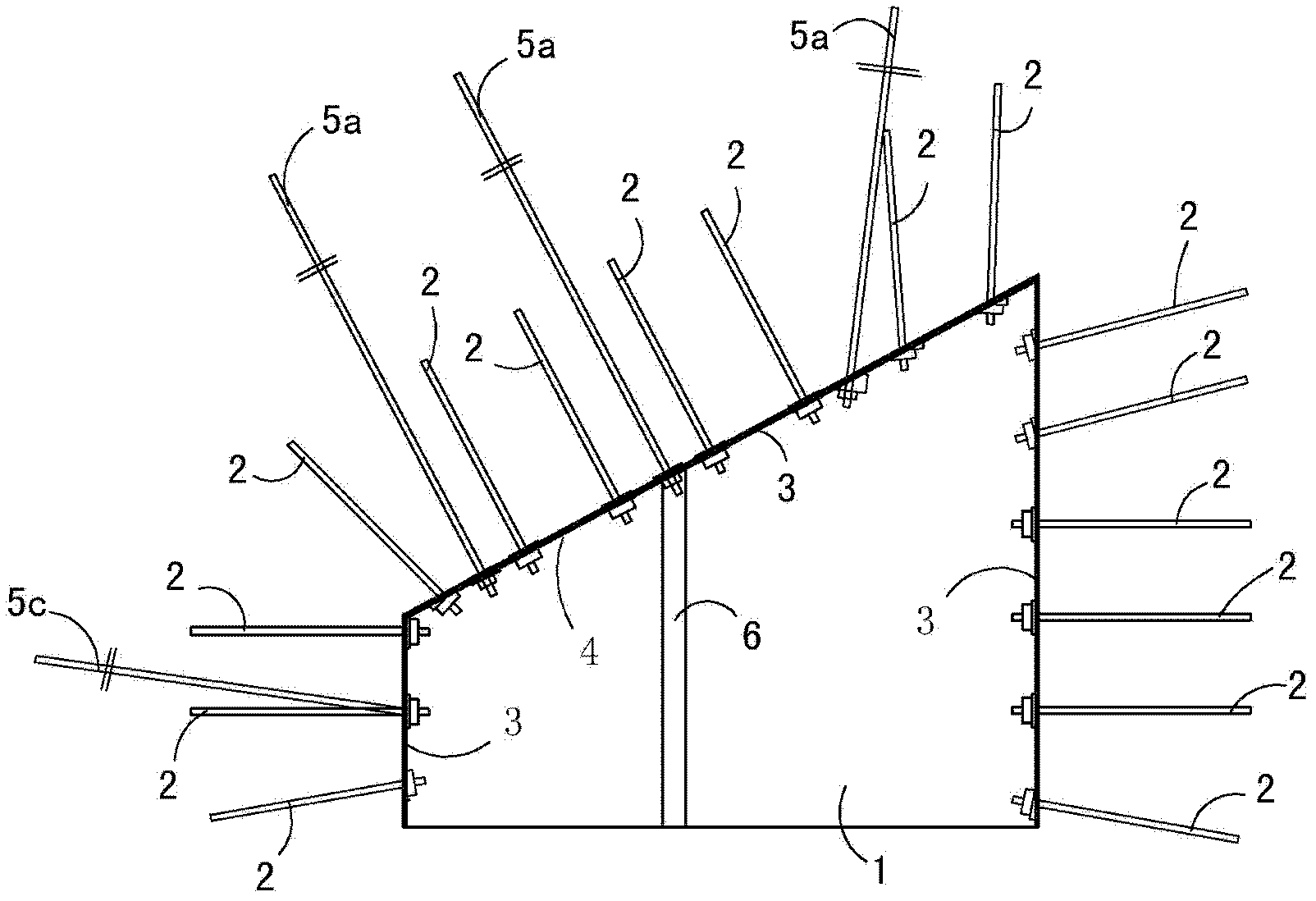

[0032] The coal seam inclination angle in the present embodiment is 28 °, figure 1 and figure 2 Shown is the solid coal recovery roadway, image 3 and Figure 4 Shown is the mining roadway with small coal pillars. The cross-sectional dimensions of the solid coal mining roadway and the small coal pillar mining roadway are: roadway width 4800mm, roadway low side height 1600mm, roadway high side height 4150mm, small coal pillar width 5000mm, using asymmetrical anchor net cables for special-shaped mining roadways with large dip angles Combined support method, the implementation steps are as follows:

[0033] 1. Excavate the roadway according to the shape of the roadway section 1, and then use the prestressed anchor rod 2, steel mesh 3 and steel belt 4 to support the roadway roof, the high side of the roadway and the surrounding rock of the low side of the roadway.

[0034] Among them, the prestressed anchor 2 adopts high-strength prestressed anchor, the diameter of the rod bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com