Dredging head in vibratin mode and application apparatus

A vibrating dredging vessel technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problems of low production efficiency and high energy consumption, and achieve reduced energy consumption, Easy to adjust and the effect of dredging depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

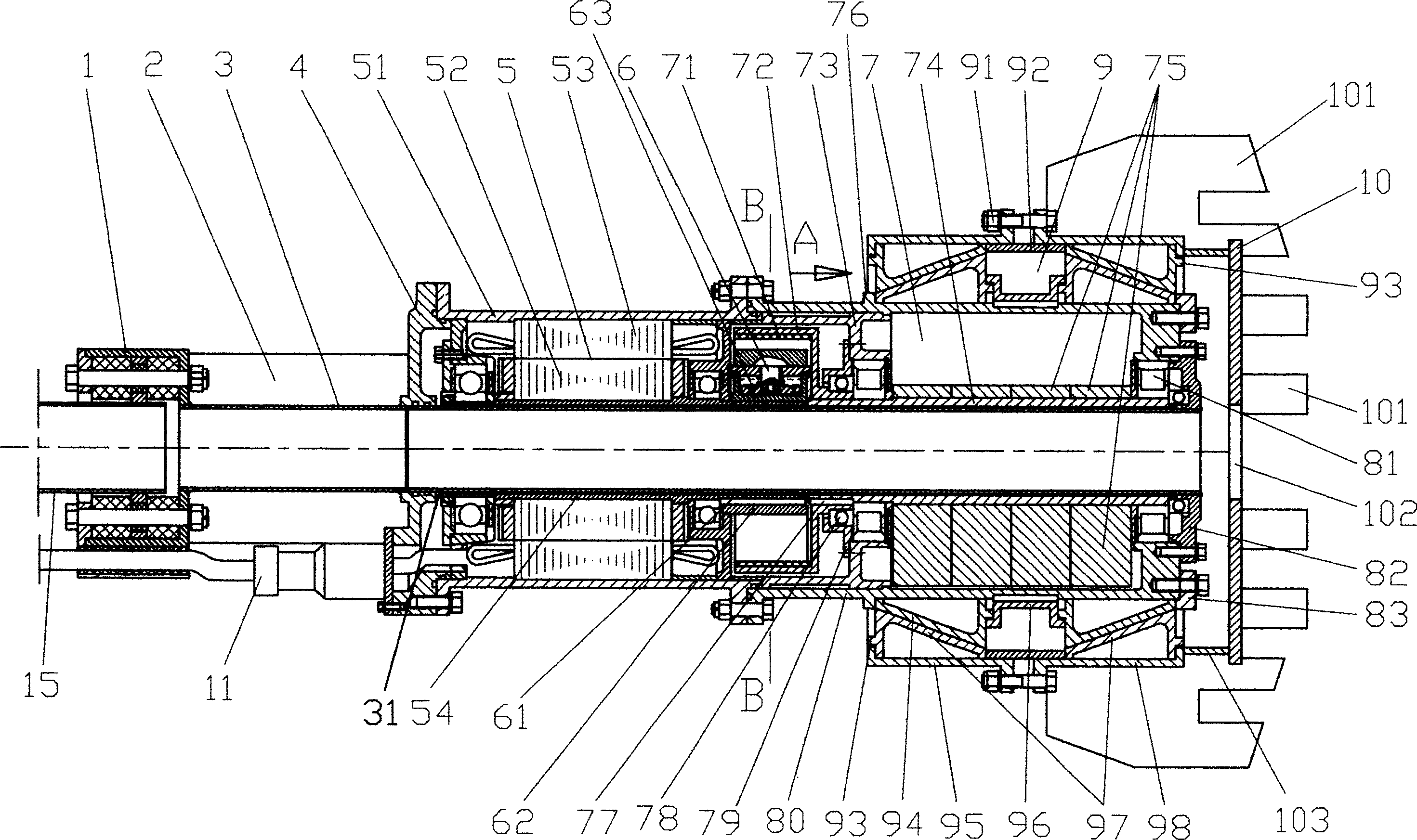

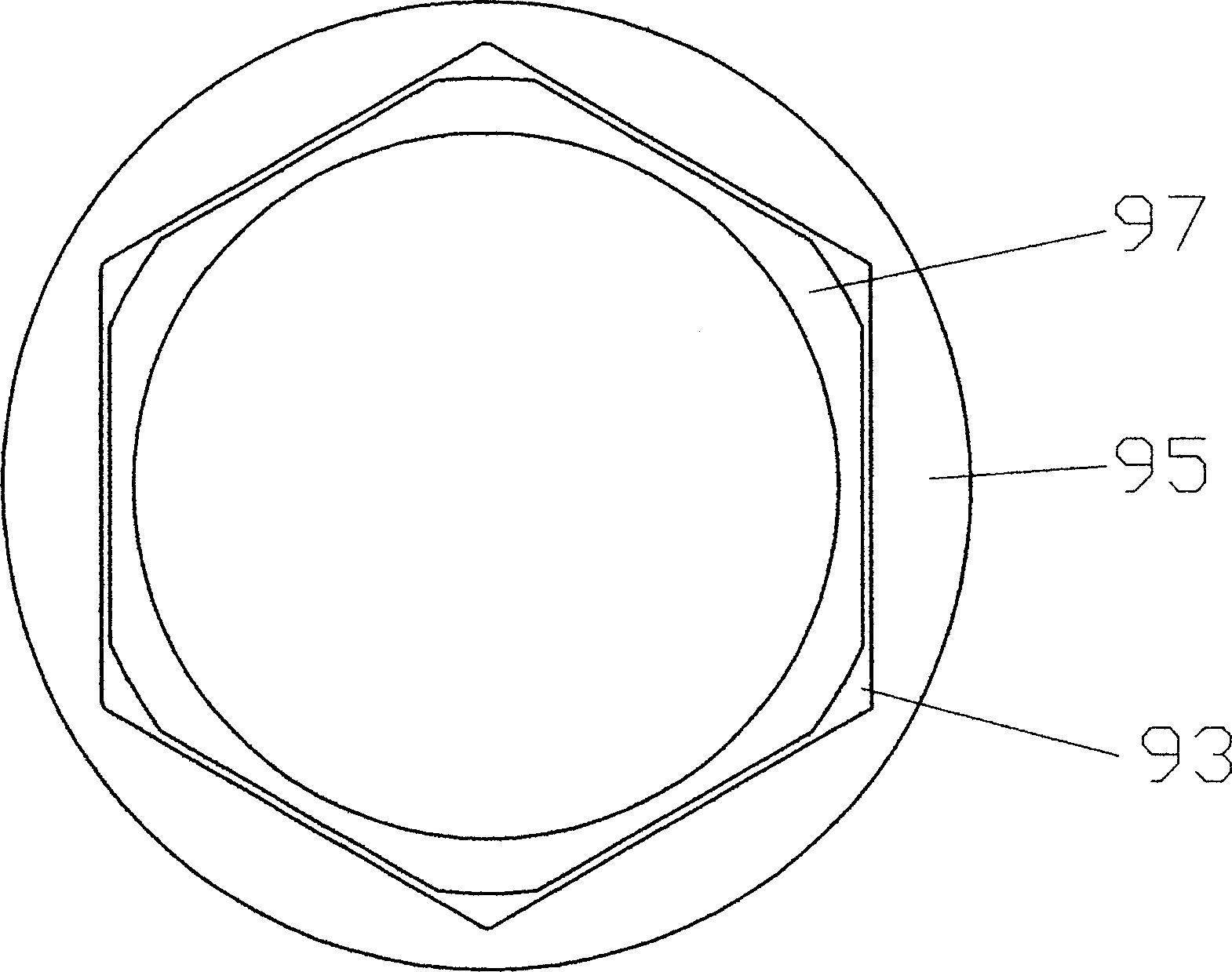

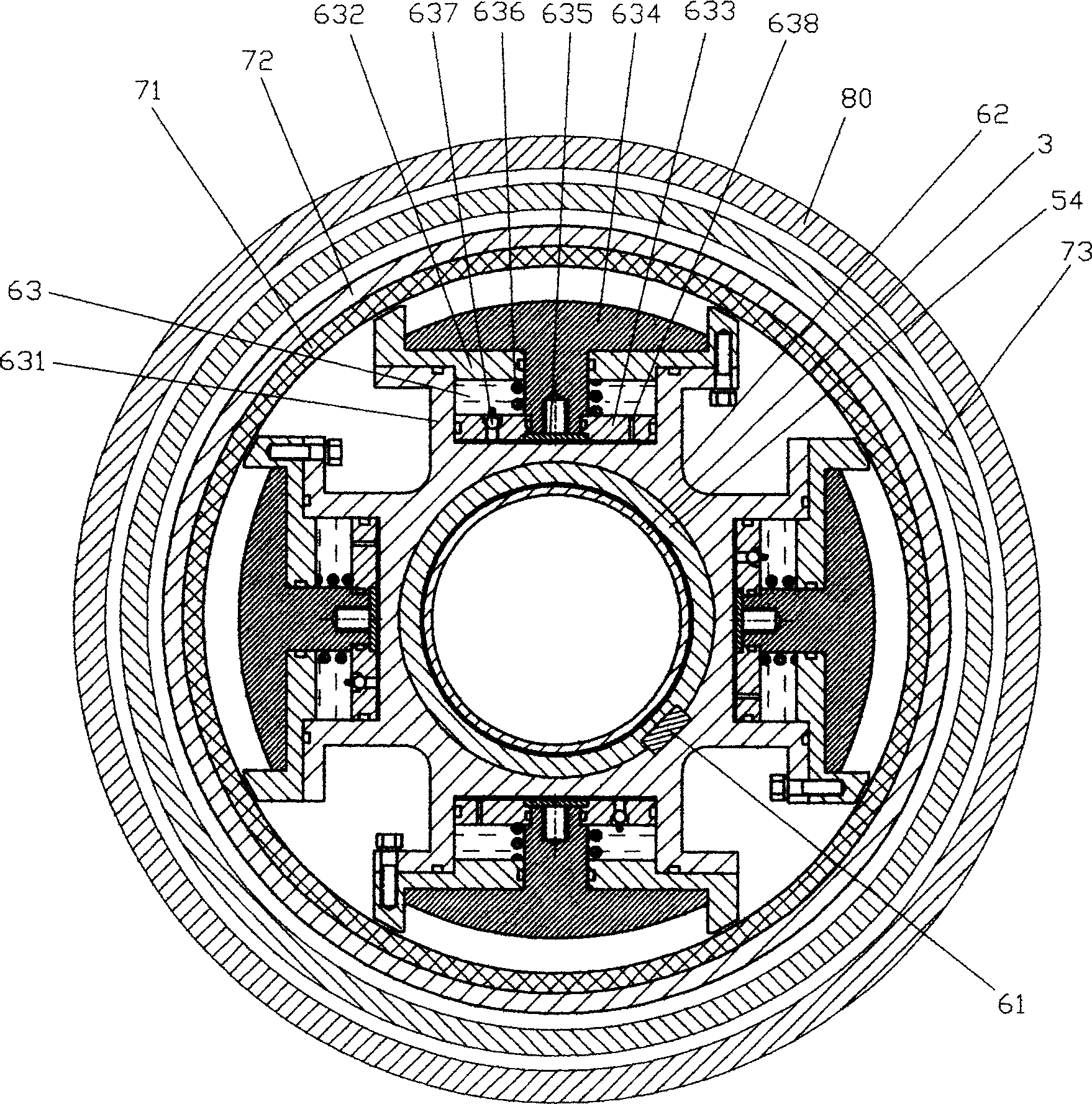

[0035] Such as figure 1 , figure 2 , image 3As shown, the vibrating dredging head of the present invention includes a rigid central muck discharge pipe 3, a motor 5, a time-delayed centrifugal clutch 6, an eccentric mass exciter 7, and a cutting cutter head rotating mechanism 9; a flange is fixed on the muck discharge pipe 3 Disk 4; the motor 5 is fixed to the ballast discharge pipe 3, wherein one end of the motor 5 housing 51 is airtightly fixed to the flange plate 4, and the hollow mandrel 54 of the motor 5 is set outside the ballast discharge pipe 3 and connected to the outside of the ballast discharge pipe 3. There is a gap between the surfaces, the motor hollow mandrel 54 has a structure to compress the motor rotor 52, and the motor casing 51 has a structure to compress the motor stator 53, and the motor winding is cured with solvent-free resin; the delay centrifugal clutch 6 includes a seat Cover 62, the seat cover 62 is provided with several damping oil cylinders 63...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com