Self-moving type bottom mud separating and collecting device

A collection device and self-propelled technology, which is applied in earth movers/shovels, mechanically driven excavators/dredgers, construction, etc., can solve the problems of too high requirements for operators, low degree of automation, and insufficient environmental protection. Achieve the effect of improving collection efficiency and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

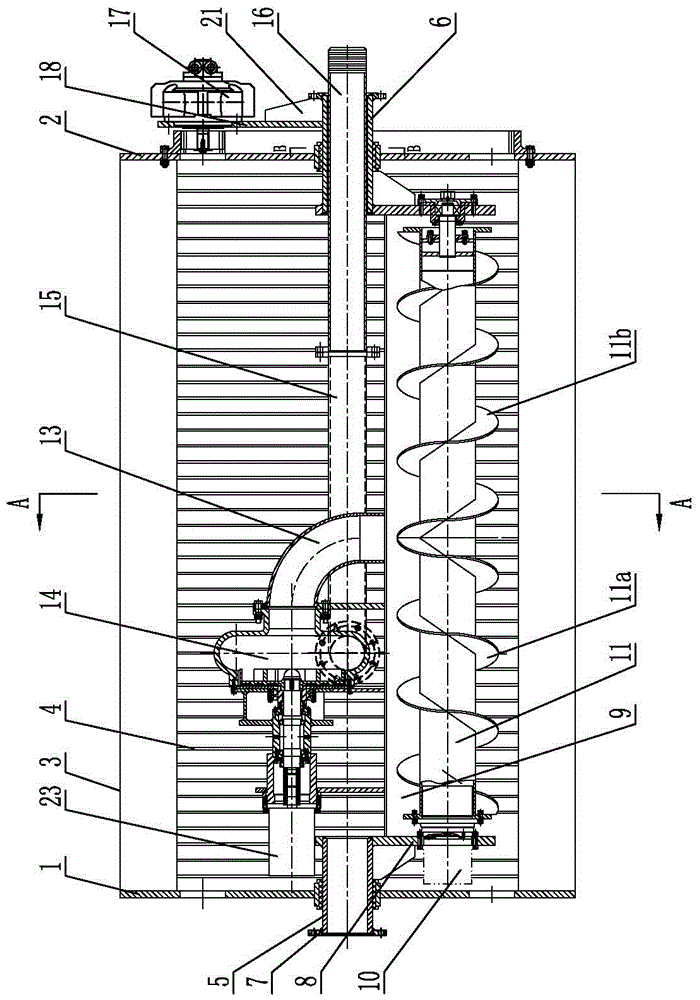

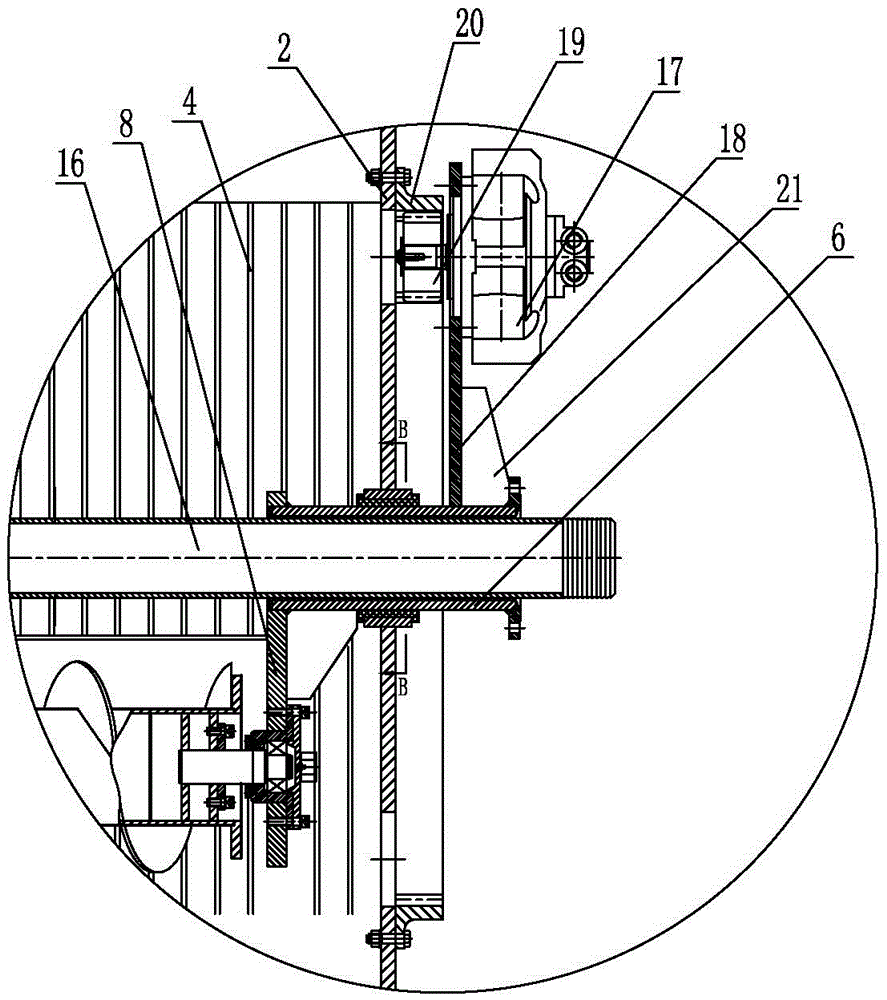

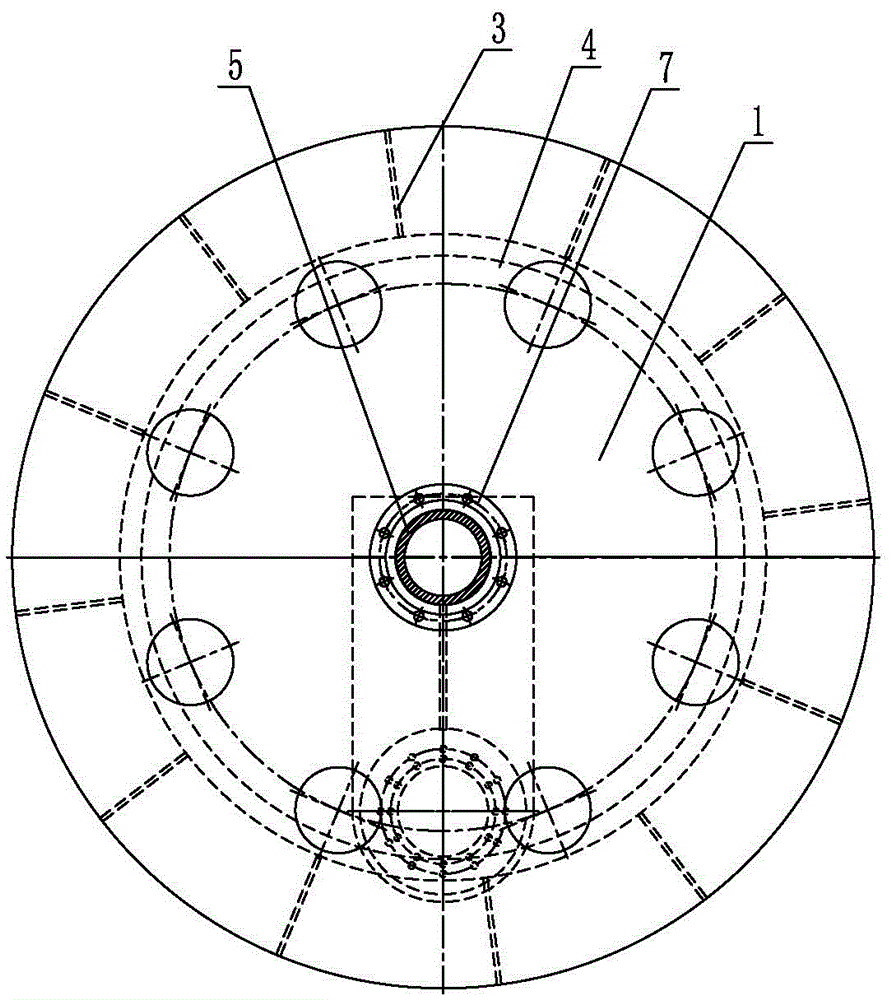

[0021] Such as Figure 1-6 As shown, it is a self-propelled sediment separation and collection device, including a walking filter mechanism. The walking filter mechanism includes a circular left end plate 1 and a right end plate 2. There are several radially arranged between the left end plate 1 and the right end plate 2. The grouser shoes 3 are connected, and a number of filter grilles 4 are arranged at intervals between the left end plate 1 and the right end plate 2; for the convenience of installation, the walking filter mechanism is a split structure, and is arranged on the left end plate 1 and the right end plate The split flange 22 on 2 is connected as a whole; the left end plate 1 and the right end plate 2 are rotatably connected to the left support tube 5 and the right support tube 6, and the split flange 22 on the left end plate 1 and the right end plate 2 passes through the sliding bearing Rotationally connected to the left support pipe 5 and the right support pipe 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com