Method for pipeline sludge cleaning and pipeline sludge cleaning robot

A technology of robots and pipelines, which is applied in the direction of cleaning sewer pipes, waterway systems, water supply devices, etc., can solve the problems of low efficiency and high labor intensity, and achieve the effects of high safety, large amount of dredging, and avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

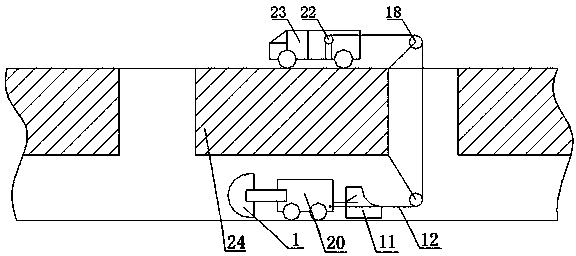

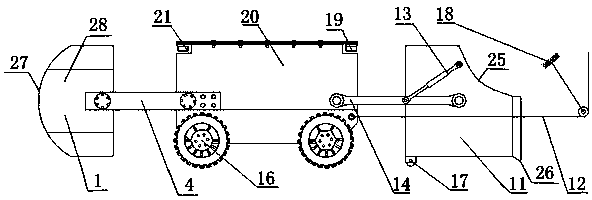

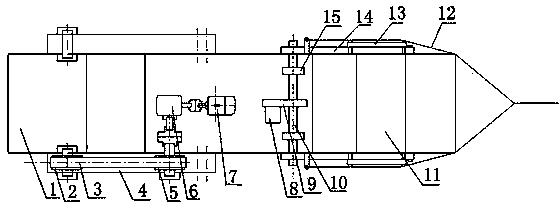

[0022] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

[0023] In an embodiment, a pipeline dredging robot includes a dredging robot car body 20, a wire rope traction device, a rear dredging bucket 1, a front dredging bucket 11, a front dredging bucket lifting mechanism and a timing belt Transmission device; the rear dredging bucket and the rear of the dredging robot body are connected by an arc-toothed synchronous belt 3 and an aluminum profile 4, and the front dredging bucket and the front of the dredging robot body are connected by a connecting rod 14 connect.

[0024] The body of the dredging robot is provided with wheels 16 at the bottom, and the self-carrying battery is used as a power source, and the movement mode of the motor-driven wheels 16 is used to drive the front dredging bucket, the rear dredging bucket and the wire rope traction device together Move towards the direction away from the wellhead of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com