Portable denitration catalyst honeycomb hole dredge

A technology of denitrification catalyst and honeycomb hole, which is applied in the field of flue gas purification, can solve the problems of low dredging efficiency, reduced catalyst reaction area, and decreased removal rate of nitrogen oxides, so as to improve dredging efficiency and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

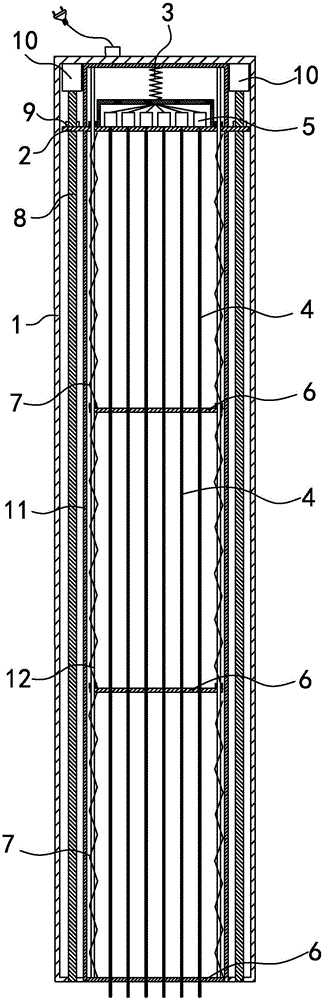

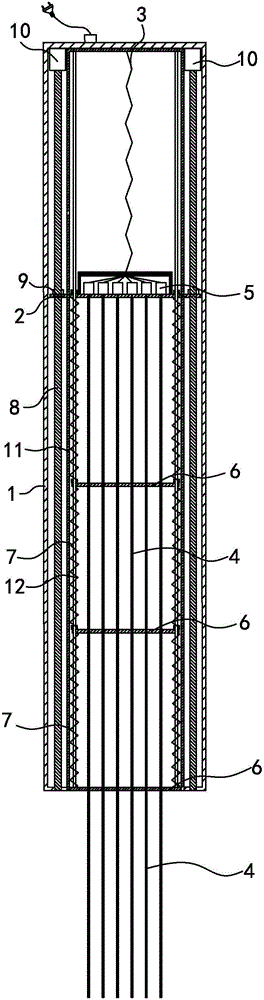

[0023] Example: A Portable Denitrification Catalyst Honeycomb Hole Dredge

[0024] See attached figure 1 and attached figure 2 As shown, it includes a casing 1, a mounting plate 2, and a dredging needle 4; the dredging pin 4 is set corresponding to the honeycomb hole of the denitration catalyst, and the mounting plate 2 is provided with a mounting hole corresponding to the dredging pin 4, and the dredging pin 4 is pierced In the corresponding installation hole, the tail end of each dredging needle 4 is connected with the rotation output shaft of a motor 5, and the motor 5 is positioned relative to the mounting plate 2, and the mounting plate 2 is relatively positioned by a linear drive mechanism. The housing 1 is slidably arranged along the axial direction of the dredging needle 4 .

[0025] The circuit wires of all the motors 5 are converged to a spiral electric wire 3 and then connected with the power wire.

[0026] Positioning plates 6 are arranged at intervals along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com