Method of treating low temperature low turbidity water by high density active mud sediment back flow

A technology for low-temperature, low-turbidity water and activated mud, applied in the field of water treatment, can solve problems such as the influence of particle concentration in water, and achieve the effects of strong shock load resistance, reduced treatment capacity, and low operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

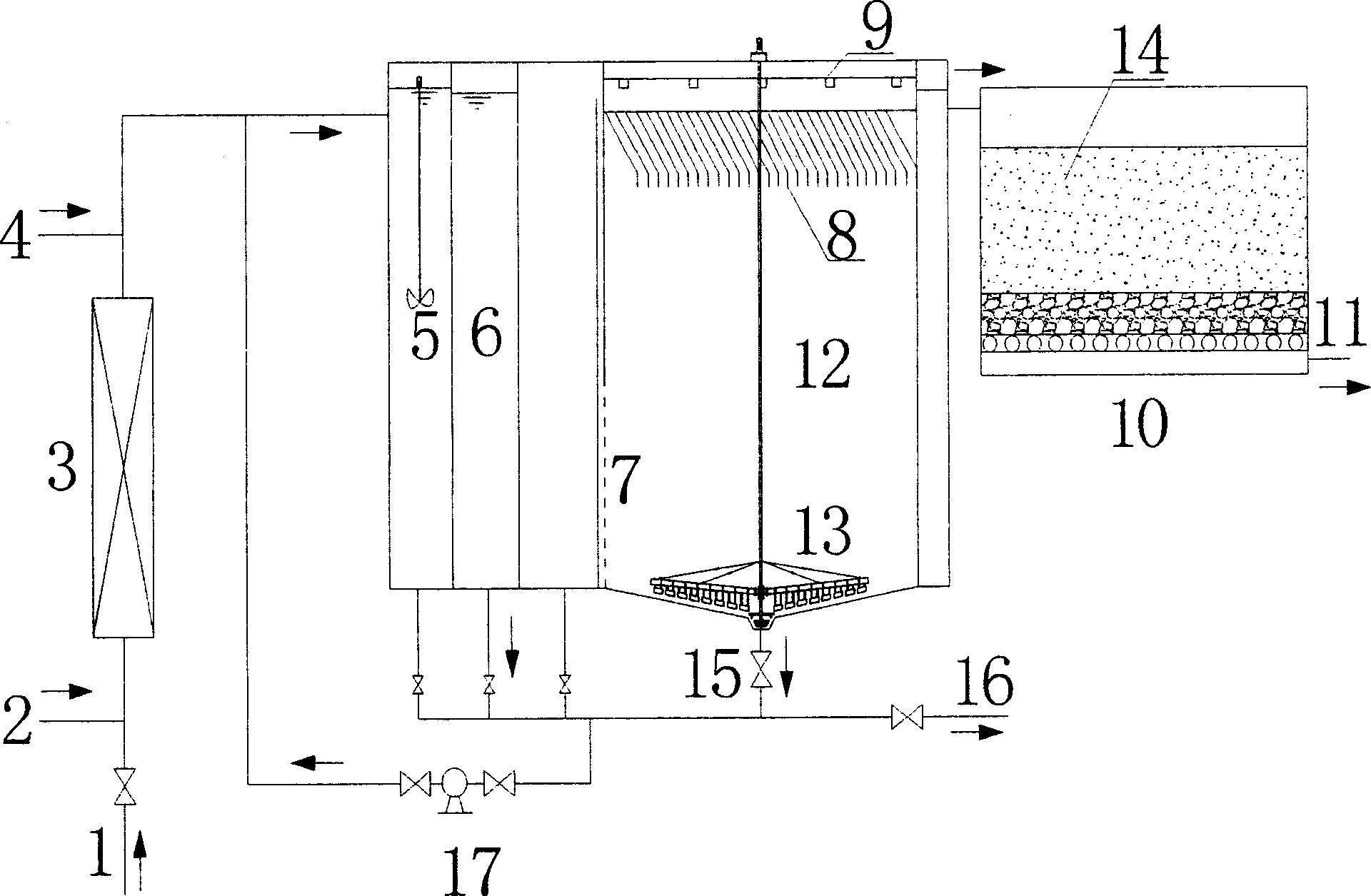

[0022] As shown in the figure, the method of high-density active sludge reflux to treat low-temperature and low-turbidity water, the equipment used includes coagulant dosing port 2, pipeline mixer 3, coagulant aid dosing port 4, mechanical stirring and mixing Chamber 5, reaction flocculation chamber 6, perforated wall 7, inclined plate device 8, outlet channel 9, filter tank 10, high-density sludge area 12, sludge scraping device 13, excess sludge discharge port 16, activated sludge return pump 17 and so on. Its processing process is:

[0023] The water entering the water inlet 1 adds coagulant through the coagulant dosing port 2, and enters the pipeline mixer 3 together, and then adds coagulant (pre-coagulation) through the coagulant dosing port 4, and then mixes with the chemical return sludge Together into the mechanical stirring mixing chamber 5. One of the impellers is located in the central steady-flow cylinder. The function of the impeller is to mix the water flow in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com