Manufacturing method of high-superposition low-loss metal magnetic powder core

A magnetic powder core, low-loss technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of poor DC superposition characteristics, high loss, and difficult to peel of metal magnetic powder core inductance, and improve the DC superposition characteristics, loss and other problems. Low, easy peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

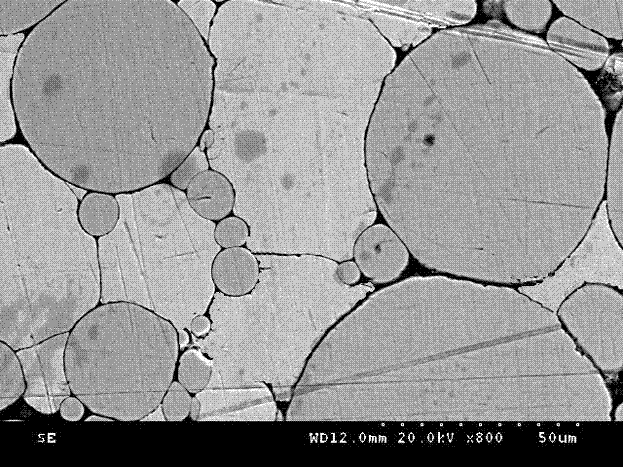

Image

Examples

Embodiment 1

[0042] (1) Take water atomized sendust magnetic powder, the mass percentage content of each component in sendust magnetic powder is: Si 8.5%, Al 6.5%, the balance is Fe, and the magnetic powder particle size ratio is -150 mesh 8% , +150~-300 mesh 55%, the balance is +300 mesh.

[0043] (2) Add the sendust magnetic powder in step (1) into the acetone phosphoric acid solution, the mass ratio of phosphoric acid to acetone in the acetone phosphoric acid solution is 1:10, and the amount of the acetone phosphoric acid solution added is 10% of the mass of the sendust magnetic powder , continuously stirred for surface passivation reaction, the surface passivation temperature was 25°C, after the acetone solution was completely volatilized, the surface passivated sendust magnetic powder was baked at a constant temperature of 65°C for 2 hours to obtain insulating sendust magnetic powder.

[0044] (3) The iron-nickel magnetic powder is atomized with water. The mass percentage content of e...

Embodiment 2

[0053] (1) Take the gas-atomized sendust magnetic powder, the mass percentage of each component in the sendust magnetic powder is: Si 10%, Al 4.5%, the balance is Fe, and the particle size ratio of the magnetic powder is -150 mesh 12 %, +150~-300 mesh 45%, the balance is +300 mesh.

[0054] (2) Add the sendust magnetic powder in step (1) into the acetone phosphoric acid solution, the mass ratio of phosphoric acid to acetone in the acetone phosphoric acid solution is 1:7, and the amount of the acetone phosphoric acid solution added is 15% of the mass of the sendust magnetic powder , continuously stirred for surface passivation reaction, the surface passivation temperature was 30°C, after the acetone solution was completely volatilized, the surface passivated sendust magnetic powder was baked at a constant temperature of 55°C for 3 hours to obtain insulating sendust magnetic powder.

[0055] (3) Take the gas-atomized iron-nickel magnetic powder. The mass percentage of each compo...

Embodiment 3

[0064] (1) Take water atomized sendust magnetic powder, the mass percentage of each component in sendust magnetic powder is: Si 8.5~10%, Al 5%, the balance is Fe, and the particle size ratio of magnetic powder is -150 mesh 10%, +150~-300 mesh 50%, the balance is +300 mesh.

[0065] (2) Add the sendust magnetic powder in step (1) into the acetone phosphoric acid solution, the mass ratio of phosphoric acid to acetone in the acetone phosphoric acid solution is 1:8, and the amount of the acetone phosphoric acid solution added is 12% of the mass of the sendust magnetic powder , continuously stirred for surface passivation reaction, the surface passivation temperature is 27°C, after the acetone solution is completely volatilized, the sendust magnetic powder after surface passivation is baked at 60°C for 2.5 hours at a constant temperature to obtain insulating sendust magnetic powder .

[0066] (3) The iron-nickel magnetic powder is atomized by water, the mass percentage of each com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com