Preparation method of core-shell magnetic microspheres

A magnetic microsphere and core-shell technology, applied in the field of preparation of core-shell magnetic microspheres, to achieve excellent electrochemical performance and electromagnetic performance, high yield, and the effect of improving electrochemical performance and electromagnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Weigh 0.4g of resorcinol and dissolve it in 83ml of a mixed reaction solvent with a volume ratio of 7:1:0.3. After the resorcinol is completely dissolved, add 0.56ml of formaldehyde and continue to stir for 24 hours at room temperature. Centrifuge, separate, wash with water and ethanol several times, and dry to obtain phenolic microspheres.

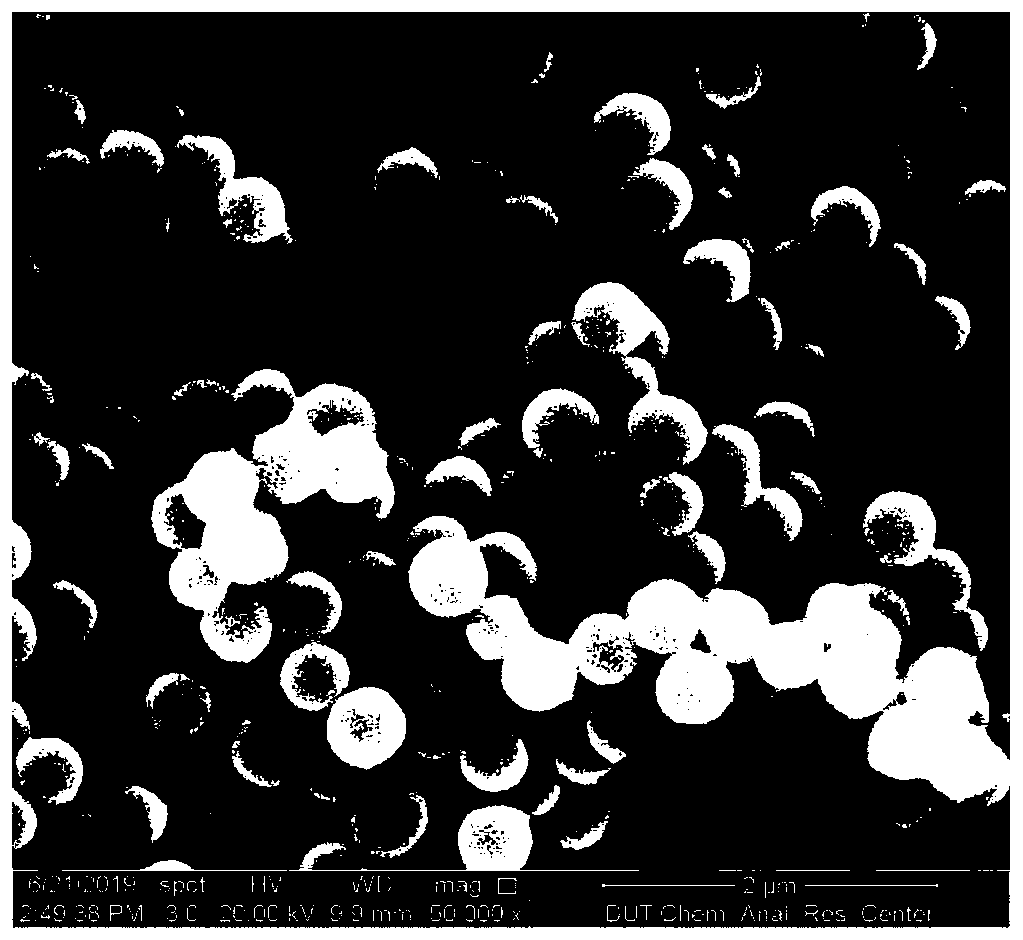

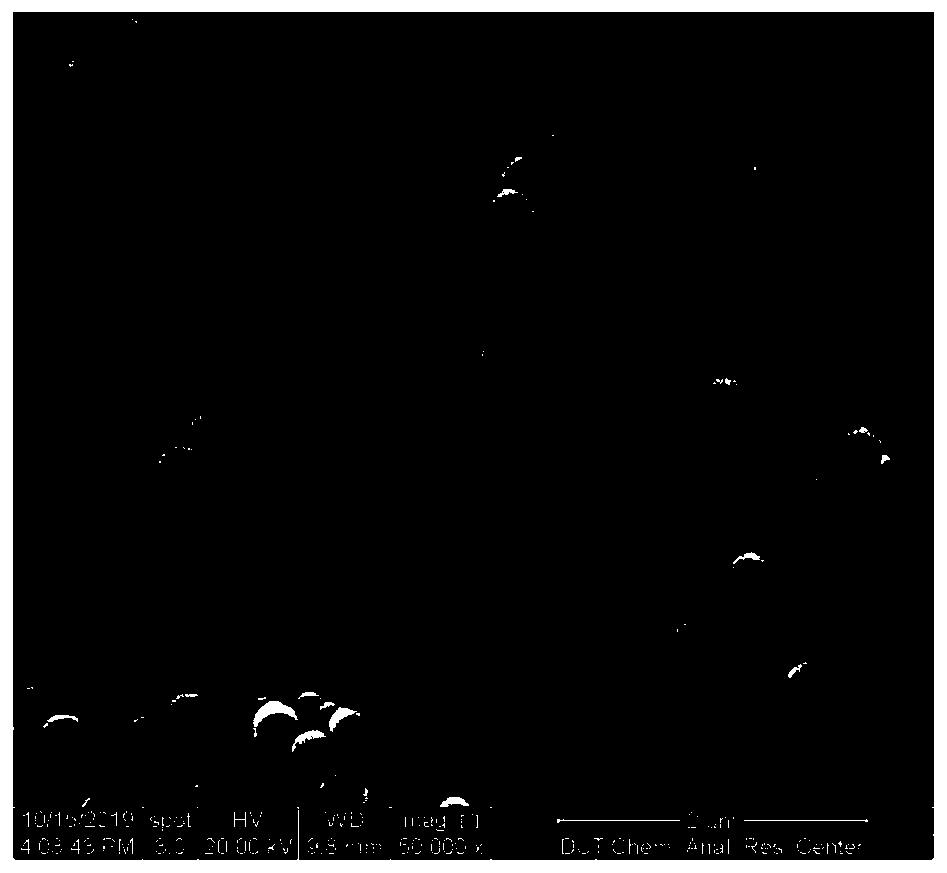

[0033] Step 2: Weigh 0.5g of phenolic microspheres and 0.0005mol of ferric nitrate and ultrasonically disperse them in a mixed solvent containing 80ml of isopropanol and 15ml of glycerin, inject them into a hydrothermal synthesis kettle with a volume of 100ml and react at 190°C for 12h, and cool naturally to room temperature. After centrifugation, separation, washing with water and ethanol for several times, and drying, put it into a tube furnace for high-temperature calcination at 700°C for 2 hours in an inert atmosphere to obtain carbon / iron tetroxide core-shell magnetic microspheres. from Figure 5 It can be seen from t...

Embodiment 2

[0035] Step 1: Add 3.46ml tetraethyl orthosilicate to 83ml mixed reaction solvent with a volume ratio of 7:1:0.3, add 0.4g resorcinol and 0.56ml formaldehyde after 60min, and continue stirring at room temperature for 24h after adding. Centrifuge, separate, wash with water and ethanol several times, and dry to obtain silica / phenolic core-shell microspheres.

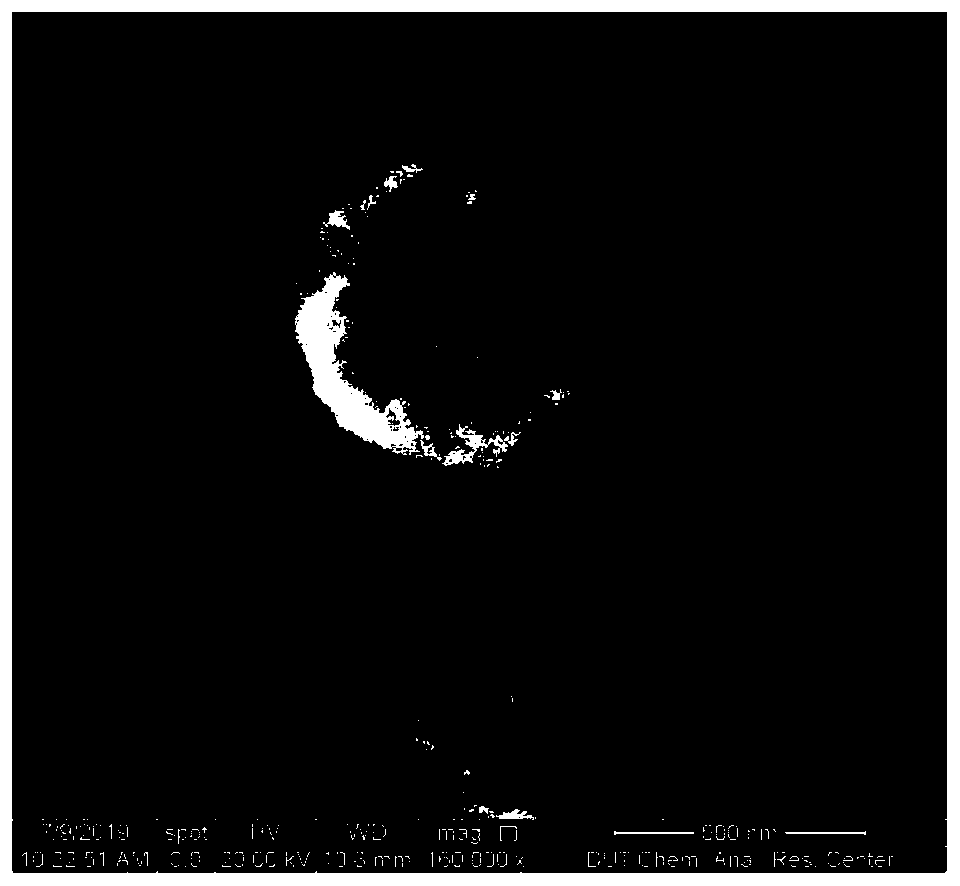

[0036] Step 2: Weigh 0.45g of silica / phenolic core-shell microspheres and 0.0005mol of ferric nitrate and ultrasonically disperse them in a mixed solvent containing 80ml of isopropanol and 15ml of glycerin, inject them into a hydrothermal synthesis kettle with a volume of 100ml and react at 190°C for 8h , naturally cooled to room temperature, centrifuged, separated, washed several times with water and ethanol, dried, put into a tube furnace in an inert atmosphere at 700 ° C for 2 h at high temperature, etched with 1 mol / L sodium hydroxide at 70 ° C for 10 hours, The hollow carbon / Fe3O4 double-shell magnetic microspheres ar...

Embodiment 3

[0038] Step 1: Add 3.46ml tetraethyl orthosilicate to 83ml mixed reaction solvent with a volume ratio of 7:1:0.3, add 0.4g resorcinol and 0.56ml formaldehyde after 60min, and continue stirring at room temperature for 24h after adding. Centrifuge, separate, wash with water and ethanol several times, and dry to obtain silica / phenolic core-shell microspheres.

[0039] Step 2: Weigh 0.3g of silica / phenolic core-shell microspheres and 0.0005mol of ferric nitrate and ultrasonically disperse them in a mixed solvent containing 80ml of isopropanol and 15ml of glycerin, inject them into a hydrothermal synthesis kettle with a volume of 100ml and react at 190°C for 12h , naturally cooled to room temperature, centrifuged, separated, washed with water and ethanol several times, dried, placed in an inert atmosphere in a tube furnace for calcination at 700°C for 2 hours, etched with 1mol / L sodium hydroxide at 60°C for 12 hours, The hollow carbon / Fe3O4 double-shell magnetic microspheres are ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com