Preparation method of superhydrophobic/superoleophilic sponge

A super-oleophilic and super-hydrophobic technology, which is applied in the field of preparation of super-hydrophobic and super-oleophilic sponges, can solve problems such as cumbersome methods, and achieve the effects of easy-to-obtain raw materials, simple preparation methods, and good self-cleaning properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

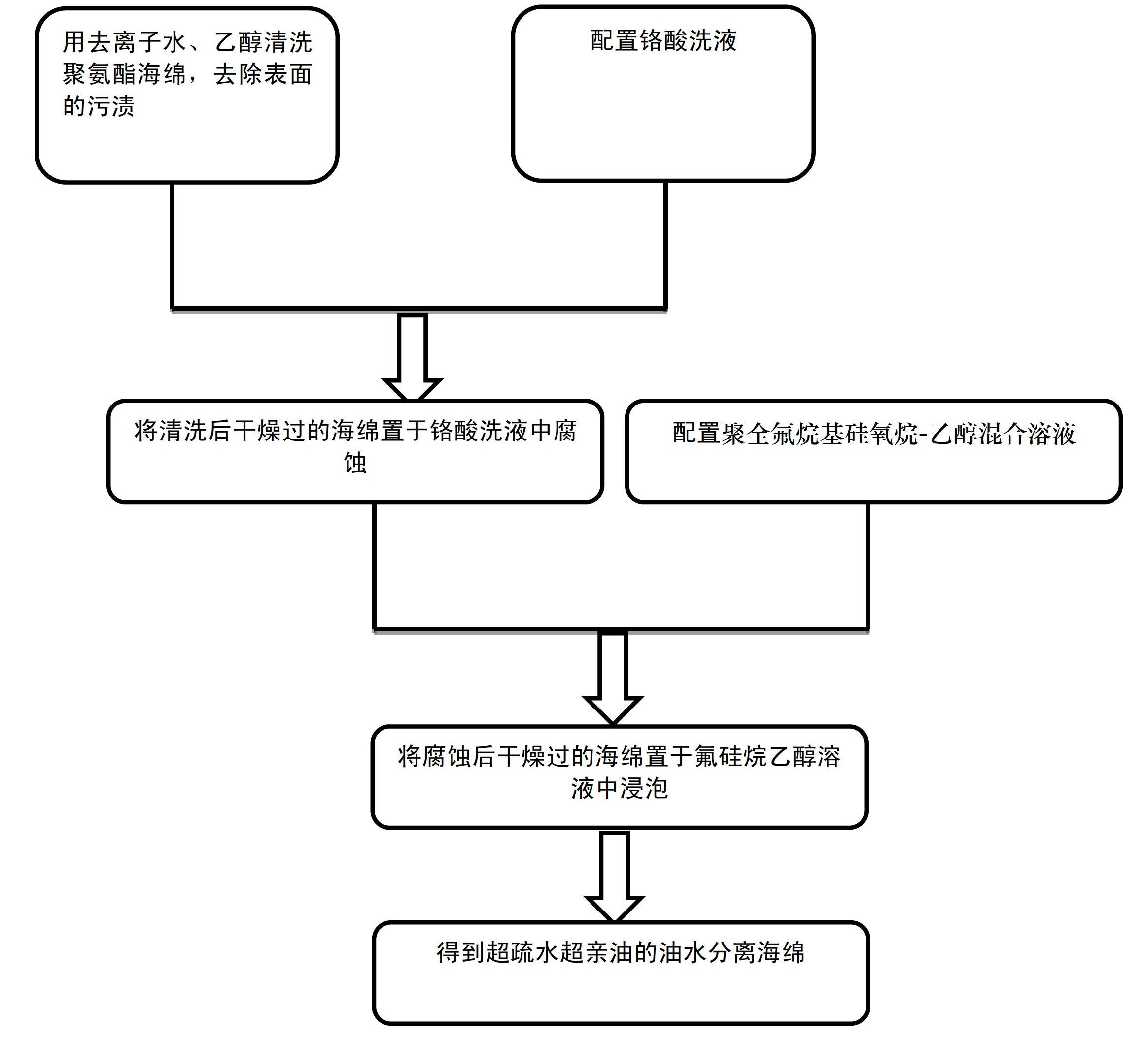

[0027] A kind of superhydrophobic superoleophilic polyurethane sponge preparation method that the present invention proposes, such as figure 1 As shown, the method includes the following steps:

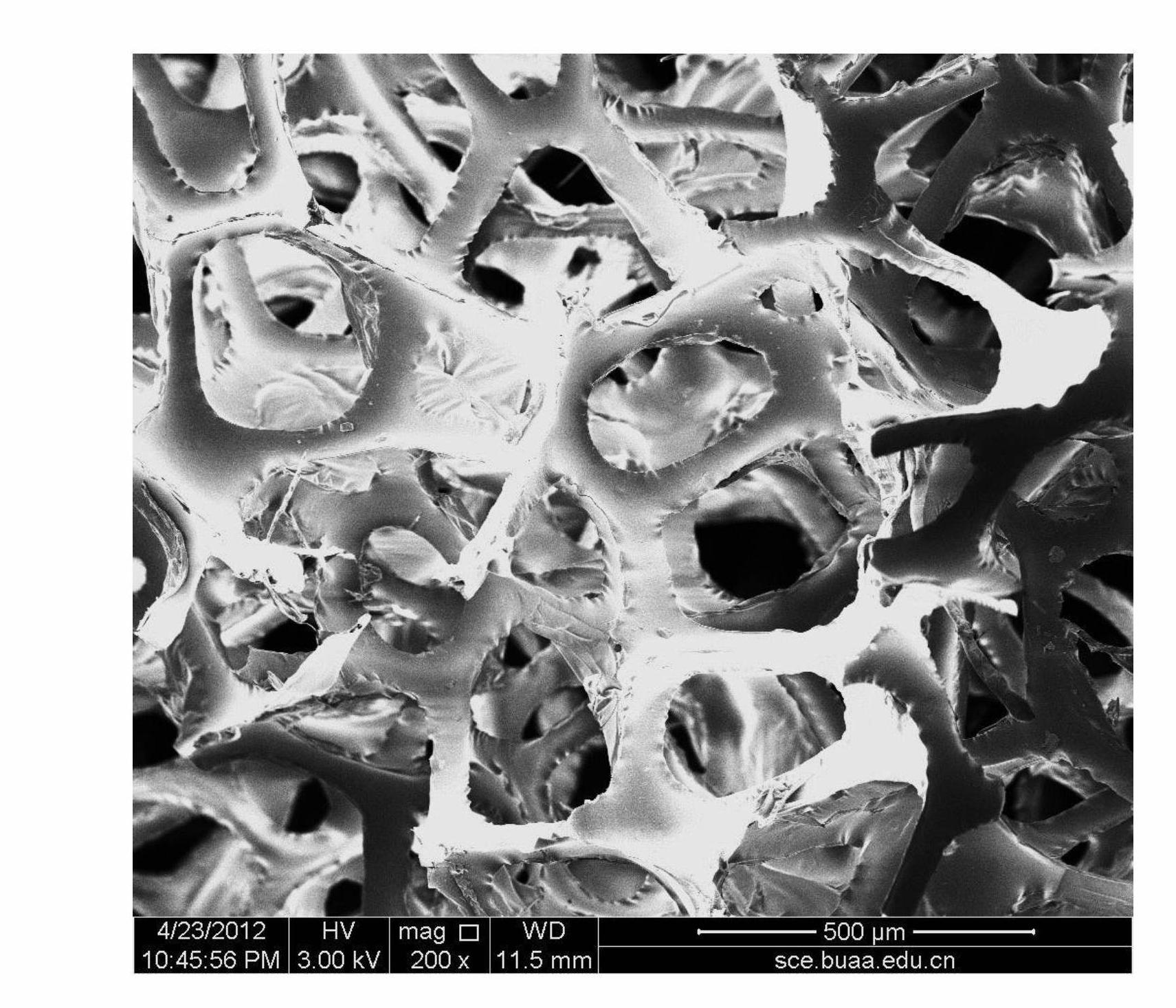

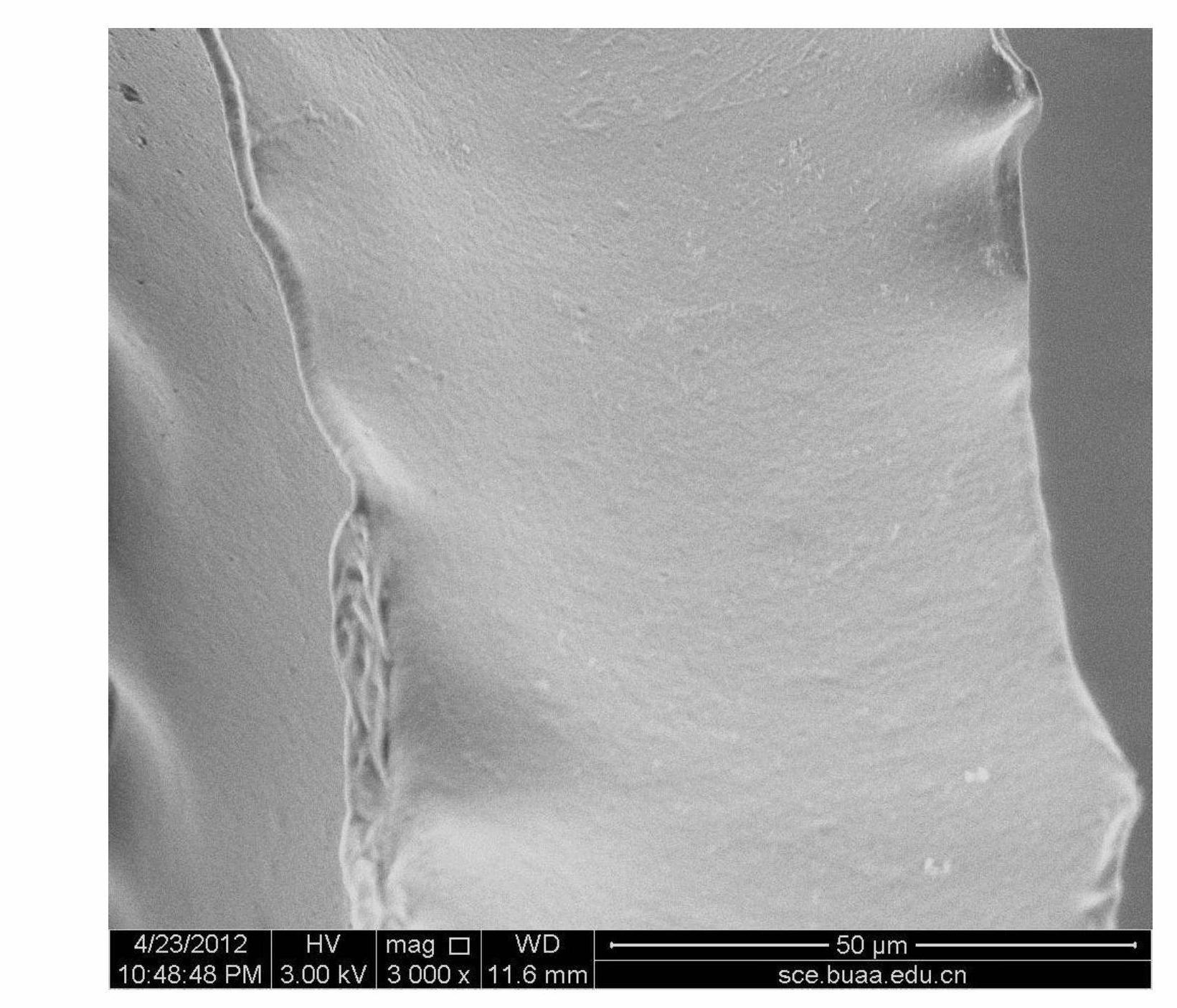

[0028] (1) Sponge pretreatment: take a beaker, pour deionized water into it for later use, immerse the polyurethane sponge in the deionized water, (the contact angle of the sponge to water is 0°, and its appearance is as follows figure 2 , image 3 As shown, the polyurethane sponge without any treatment has no micro-nano structure, and the size of the polyurethane sponge is preferably 50mm×100mm×10mm), put the beaker into the ultrasonic device for 30-90 minutes to clean the stain on the surface of the sponge; Pour out the cleaning solution, pour absolute ethanol (analytical alcohol, ethanol mass fraction ≥ 99.7%) into the beaker, continue to ultrasonically clean the polyurethane sponge for 30-90 minutes, remove the grease on the polyurethane sponge, and then dry (oven temperature 60...

Embodiment 1

[0036] A kind of superhydrophobic superoleophilic polyurethane sponge preparation method that present embodiment proposes, this method comprises the following steps:

[0037] (1) Sponge pretreatment: Take a beaker, pour deionized water into it for later use, immerse the polyurethane sponge (50mm×100mm×10mm in size) in deionized water, put the beaker into the ultrasonic device for 30 minutes to clean the surface of the sponge Stains: Pour out the cleaning solution, pour absolute ethanol (analytical alcohol, ethanol mass fraction ≥ 99.7%) into the beaker, continue to ultrasonically clean the polyurethane sponge for 30 minutes, remove the grease on the sample, and then dry it (oven temperature 60 ℃) for use;

[0038] (2) Preparation of chromic acid lotion: Measure 20ml of deionized water, pour it into a 500ml beaker for later use, weigh 10g of potassium dichromate, pour it into a beaker filled with 20ml of deionized water, and then measure 180ml Concentrated sulfuric acid (98wt%...

Embodiment 2

[0045] A kind of superhydrophobic superoleophilic polyurethane sponge preparation method that present embodiment proposes, this method comprises the following steps:

[0046] (1) Sponge pretreatment: take a beaker, pour deionized water into it for later use, immerse the polyurethane sponge (70mm×80mm×15mm) in deionized water, put the beaker into the ultrasonic device for 40 minutes to clean the stain on the surface of the sponge; Pour out the cleaning solution, pour absolute ethanol (analytical alcohol, ethanol mass fraction ≥ 99.7%) into the beaker, continue to ultrasonically clean the polyurethane sponge for 40 minutes, remove the grease on the sample, and then dry (oven temperature 70°C) stand-by;

[0047] (2) Preparation of chromic acid lotion: Measure 40ml of deionized water, pour it into a 500ml beaker for later use, weigh 8g of potassium dichromate, pour it into a beaker filled with 40ml of deionized water, and then measure 150ml Concentrated sulfuric acid (97wt%) is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com