Process method for recovering chromium and aluminum by comprehensively utilizing waste aluminum residues

A process method and waste recycling technology, which is applied in the field of recycling sodium dichromate and alumina, can solve the problems of high impurity content, affecting the quality of alumina products, etc., and achieve the effects of increasing economic benefits, easy implementation of production conditions, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A process method for comprehensively utilizing aluminum mud waste to recover chromium and aluminum. The specific steps are as follows:

[0026] (1) Preliminary chromium removal by beating and washing

[0027] According to the ratio of aluminum mud mass (g): water volume (ml) of 1:3, the aluminum mud is mixed with water, heated to 65° C. and kept warm, and stirred for 145 minutes at a rotation speed of 200 r / min. Centrifuge is used for solid-liquid separation, and the supernatant and sediment are collected separately, and the supernatant is returned to the chromium salt production process for recycling, and the sediment is used for further chromium removal.

[0028] (2) Electrodialysis to remove chromium

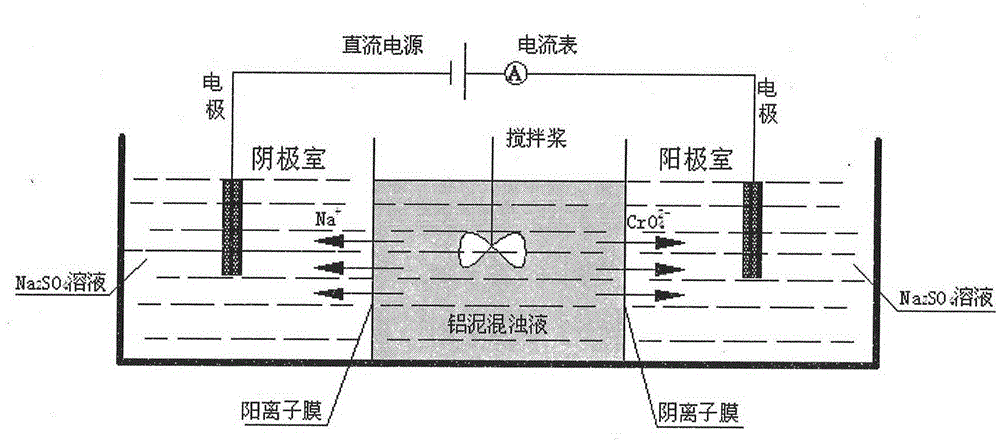

[0029] ① Design of electrodialysis device

[0030] The main body of the electrodialysis device is a rectangular parallelepiped water tank made of organic glass. The water tank is divided into three independent spaces: a cathode chamber, an intermediate chamber, and an anode cha...

Embodiment 2

[0039] A process method for comprehensively utilizing aluminum mud waste to recover chromium and aluminum is the same as implementation case 1, in which:

[0040] In step (1), the ratio of the mass (g) of the aluminum mud: the volume (ml) of the water is 1:2, heat to 60°C and keep it warm, and stir for 90 minutes at a rotation speed of 180r / min.

[0041] In steps (2)-②, the sediment obtained in step (1), that is, the aluminum sludge after preliminary chromium removal, is based on the ratio of the mass (g) of the aluminum sludge to the volume (ml) of water (ml) as 1:5 After being mixed evenly, it is added to the middle chamber of the electrolytic cell as the raw material for electrodialysis. A 0.1mol / L sodium sulfate solution was prepared and added to the cathode chamber and anode chamber at both ends of the electrolytic cell as the working medium. Put the electrolytic cell into a water bath heating tank, heat it to 30°C and keep it warm. Turn on the stirring device, keep the spee...

Embodiment 3

[0047] A process method for comprehensively utilizing aluminum mud waste to recover chromium and aluminum is the same as implementation case 1, in which:

[0048] In step (1), the ratio of the mass (g) of the aluminum mud: the volume (ml) of the water is 1:5, heat to 70° C. and keep it warm, and stir for 180 min at a rotation speed of 240 r / min.

[0049] In steps (2)-②, the sediment obtained in step (1), that is, the aluminum sludge after preliminary chromium removal, is based on the ratio of the mass of aluminum sludge (g) to the volume of water (ml) as 1:8 After being mixed evenly, it is added to the middle chamber of the electrolytic cell as the raw material for electrodialysis. A 1mol / L sodium sulfate solution was prepared and added to the cathode chamber and anode chamber at both ends of the electrolytic cell as the working medium. Put the electrolytic cell into a water bath heating tank, heat it to 40°C and keep it warm. Turn on the stirring device, keep the speed of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com