Method for preparing integral macroporous alumina

A monolithic, large-pore technology, applied in chemical instruments and methods, alumina/aluminum hydroxide, catalyst carriers, etc., can solve the problems of disconnected pores, excessive filling, and reduced mechanical strength, and achieve a simple and easy preparation process , simple operation, cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

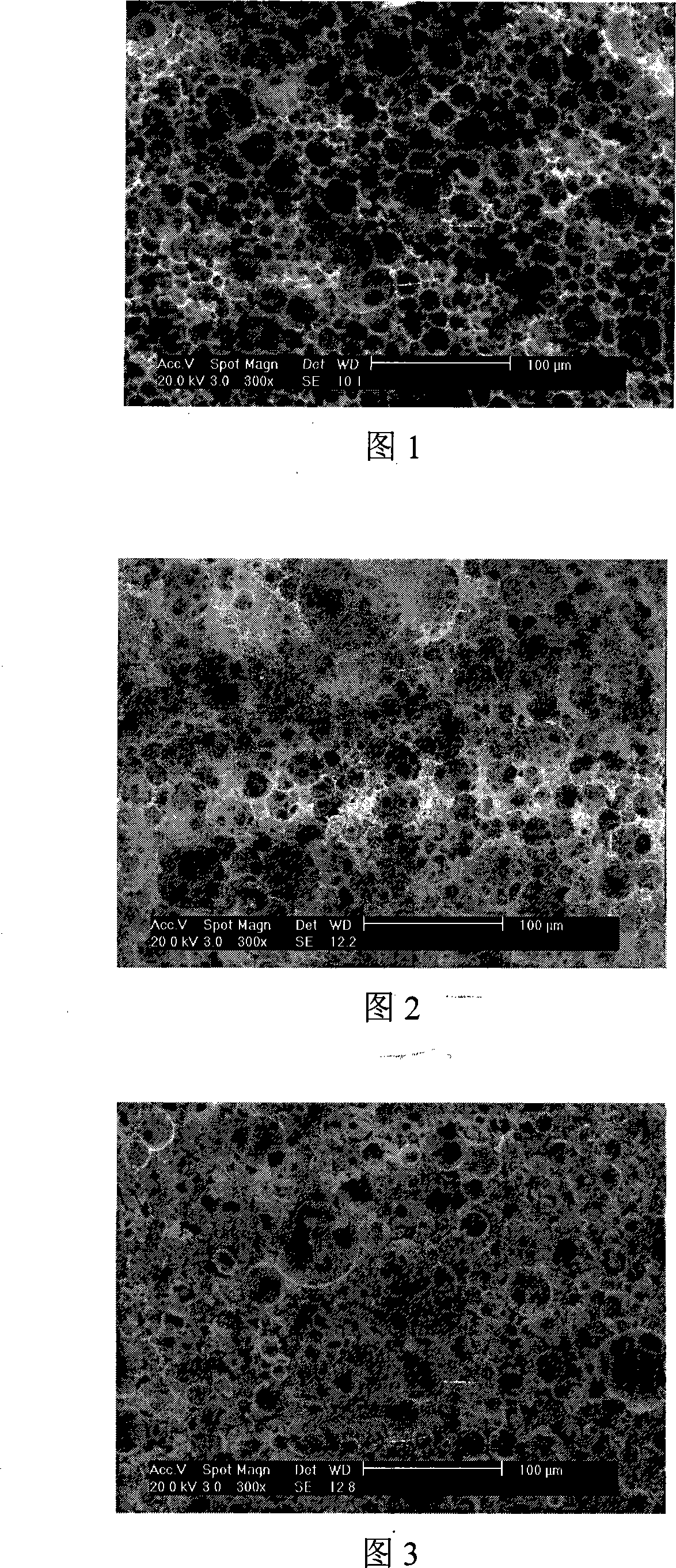

Embodiment 1

[0020] (1) Preparation of monolithic macroporous polystyrene template by inverse concentrated emulsion method

[0021] Styrene and divinylbenzene monomers were washed 4 times with an equal volume of 0.2 mol / L NaOH solution, and then washed 4 times with an equal volume of deionized water for later use. Accurately weigh 6 mL of washed styrene and 1.5 mL of divinylbenzene, and put them into a 100 mL three-necked bottle. Add 0.062g of initiator azobisisobutyronitrile and 0.54g of surfactant Span 80 therein, and stir at 400r / min to make them evenly mixed. Slowly add 33.9 mL of deionized water dropwise into the three-necked flask under stirring, and the dropping time is controlled at 60 min to form a reverse-phase thick emulsion. After continuing to stir for 30 minutes, the concentrated emulsion was moved into a mold, and placed in a constant temperature oven at 60°C for polymerization for 24 hours. The polymerized template was dried at 60° C. for 48 hours to obtain a monolithic m...

Embodiment 2

[0029] Prepare monolithic macroporous alumina by the method described in embodiment 1, Al 2 o 3 The preparation method of the sol is as follows: Accurately weigh 4.000g of pseudoboehmite (AlOOH), add it into a round-bottomed flask containing 50mL of deionized water under stirring conditions, add concentrated nitric acid for peptization, adjust pH=3.5, and Stirring and aging for 2h, translucent Al 2 o 3 Sol. The monolithic macroporous Al oxide prepared by this method 2 o 3 The average pore diameter is 14 μm.

Embodiment 3

[0031] The preparation method and process were the same as in Example 1, but the volume of deionized water added in step (1) was changed to 22.5mL, and the monolithic macroporous Al oxide 2 o 3 The average pore diameter is 8 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com