Catalyst for preparing methylbenzene by methanol conversion and preparation method and application thereof

A methanol conversion and catalyst technology, which is applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of not involving material recycling and low total conversion rate of methanol, so as to improve the thermal effect of equilibrium reaction and improve The total yield of aromatics and the effect of large amount of raw material treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

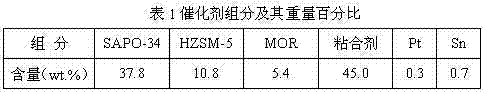

Embodiment 1

[0038] The composite molecular sieve is prepared by a mixing method, and the mixed molecular sieve is SAPO-34, HZSM-5 and MOR, and the molar ratio of silicon to aluminum of the HZSM-5 molecular sieve is 50. SAPO-34, HZSM-5 and MOR molecular sieves and binder γ-Al 2 o 3 Stir well, mix evenly, and make a mixture for later use. Add 4 wt.% dilute nitric acid aqueous solution to the mixture, knead it, and then extrude it. o Dried at C, then crushed into 10-40 mesh particles, and dried at 550 o C roasting for 5 hours. The modifier elements are added to the prepared mixture by step-by-step impregnation, and the nitrate impregnation process of each modifier element is as follows: transfer an appropriate amount of small particles of the mixture to a certain concentration of the modifier In the aqueous solution of soluble salt, the ratio of the volume of the mixture particles to the volume of the impregnating liquid is 1.5, at 90 o C. Immerse for 2 hours under the condition of cont...

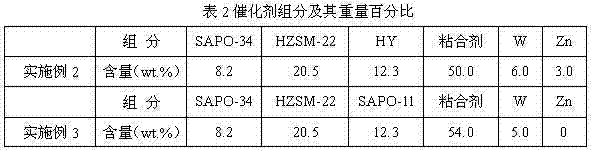

Embodiment 2-3

[0041] Composite molecular sieve is prepared by mixing method, the mixed molecular sieve is SAPO-34, HZSM-22 and HY or SAPO-11, molecular sieve and binder γ-Al 2 o 3 Stir well, mix evenly, and make a mixture for later use. Add 4 wt.% dilute nitric acid aqueous solution to the mixture, knead it, and then extrude it. o Dried under C, then, crush it into 10-40 mesh particles, and dry it at 500 o C roasting for 8 hours. The modifier element zinc nitrate or ammonium tungstate is added to the prepared mixture respectively by step-by-step impregnation. The impregnation process of each modifier element is as follows: transfer an appropriate amount of small particles of the mixture to a certain concentration of In the aqueous solution of the soluble salt of the modifying agent, the ratio of the volume of the mixture particles to the volume of the impregnating liquid is 2, and at 60 o C. Immerse for 3 hours under the condition of continuous stirring. After the impregnating liquid e...

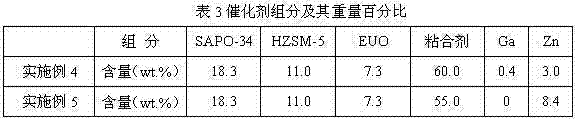

Embodiment 4-5

[0044] The composite molecular sieve is prepared by a mixing method, the mixed molecular sieve is SAPO-34, HZSM-5 and EUO, and the molar ratio of silicon to aluminum of the HZSM-5 molecular sieve is 90. EUO, HZSM-5 and SAPO-34 molecular sieves and binder γ-Al 2 o 3 Stir well, mix evenly, and make a mixture for later use. Add 2 wt.% dilute nitric acid aqueous solution to the mixture, knead it, and then extrude it. o Dried at C, then crushed into 10-40 mesh particles, and dried at 550 o C roasting for 6 hours. The modifier element nitrate is added to the prepared mixture separately by step-by-step impregnation method. The impregnation process of each modifier element is as follows: transfer an appropriate amount of small particles of the mixture to a certain concentration of the modifier. In the aqueous solution of soluble salt, the ratio of the volume of the mixture particles to the volume of the impregnating liquid is 1, at 80 o C. Immerse for 3 hours under the condition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com