A reactor and a method of preparing pseudoboehmite by the reactor

A technology for reactors and cylinders, applied in the field of preparing pseudo-boehmite and reactors for preparing pseudo-boehmite, which can solve the problem of dispersed aluminum hydroxide particle size distribution, non-concentrated distribution of catalyst carrier pores, and inconsistent product properties. It is possible to achieve consistency and other problems, and achieve the effect of uniform particle size, uniform properties, and large pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

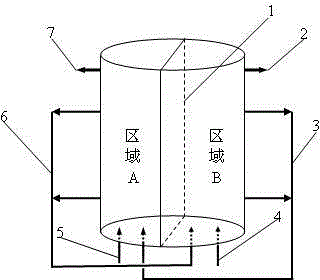

[0042] use figure 1 In the shown reactor, the partition 1 divides the reactor cavity evenly into two regions. The total volume of the reactor is 800mL, and the volume of each region is about 400mL. The process is as follows: Aluminum sulfate solution (80g Al 2 o 3 / L) and sodium metaaluminate solution (200gAl 2 o 3 / L) respectively enter the reactor from the feed port I4 and feed port II5 at the lower part of the reaction cylinder, control the gelling temperature to 70°C, control the pH value of the slurry in the acidic zone B to 3, and the pH of the slurry in the alkaline zone A The pH value is 8.5, start the circulation system in A and B areas, the circulation line I 3 circulates the acidic slurry to the bottom of the alkaline area A at a circulation rate of 36mL / min, and flows into the A area in parallel with the sodium metaaluminate solution II5 , control the feed flow rate of sodium metaaluminate solution to 27mL / min; similarly, the circulation line II 6 circulates the...

Embodiment 2

[0044] The preparation process is as in Example 1, except that the gelling temperature is controlled at 90°C, the pH value of the mixed slurry is adjusted to 9 with potassium carbonate solution, the aging temperature is 90°C, and the aging time is 30 minutes, then washed and dried at 150°C for 4 hours , the physical and chemical properties of the prepared pseudo-boehmite are shown in Table 1.

Embodiment 3

[0046] The preparation process is as in Example 1, except that the control is as follows: the circulation volume in the circulation line II 6 is 40mL / min, the sodium metaaluminate solution is added from II 5 at a speed of 30mL / min, and at the same time, the slurry circulation in the circulation line I 3 is controlled The volume is 50mL / min, and the aluminum sulfate solution is added from I4 at a rate of 50mL / min. The physical and chemical properties of the prepared pseudo-boehmite are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com