Method for continuously producing pseudoboehmite

A technology of pseudo-boehmite and sodium metaaluminate, applied in alumina/aluminum hydroxide and other directions, can solve the problems of large fluctuation of product quality, high labor intensity and low productivity, and achieve stable product quality and low labor intensity. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

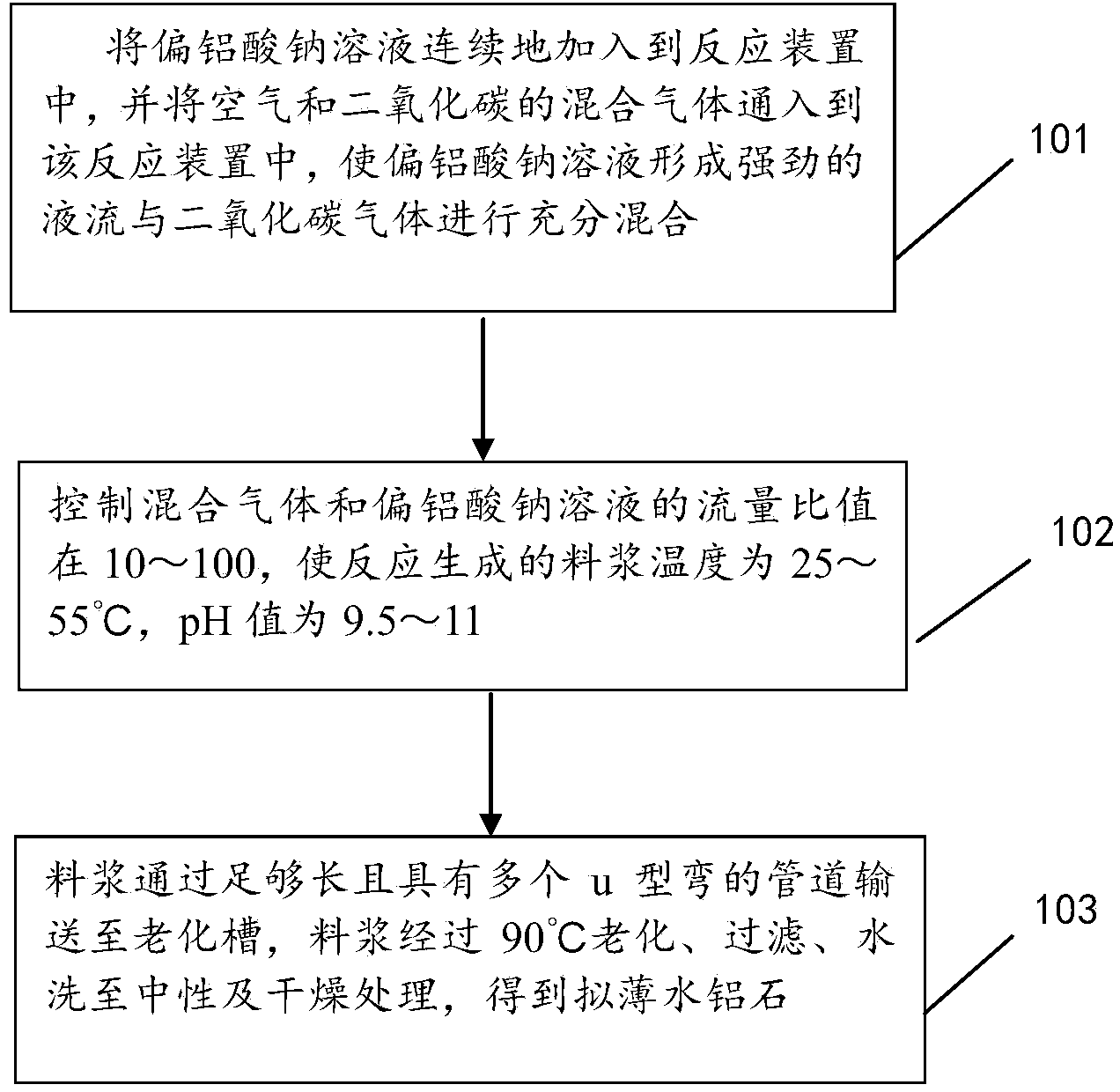

Method used

Image

Examples

Embodiment 1

[0033] The sodium metaaluminate solution with an alumina concentration of 15.3g / L is continuously added to the reaction device through a pump, and a mixed gas of air and carbon dioxide is introduced. The volume percentage of carbon dioxide in the mixed gas is 30%, and the pressure of the mixed gas is 0.1MPa, so that the sodium metaaluminate solution forms a strong liquid flow and fully mixes with carbon dioxide gas to produce many and delicate bubbles; control the flow ratio of the mixed gas and sodium metaaluminate solution to 10, so that the temperature of the slurry generated by the reaction When the temperature is 25°C and the pH value is 9.5, the gelation is stopped; the slurry obtained from the reaction is transported to the aging tank through a pipeline that is long enough and has multiple U-shaped bends, and the temperature of the slurry is raised in the aging tank, and the aging temperature is 90°C ; Filter the aged slurry, wash the filter cake until neutral; dry the w...

Embodiment 2

[0035] The sodium metaaluminate solution with an alumina concentration of 23.5g / L is continuously added to the reaction device through a pump, and a mixed gas of air and carbon dioxide is introduced. The volume percentage of carbon dioxide in the mixed gas is 40%, and the pressure of the mixed gas is 0.12MPa, so that the sodium metaaluminate solution forms a strong liquid flow and fully mixes with carbon dioxide gas to produce many and delicate bubbles; control the flow ratio of the mixed gas and sodium metaaluminate solution to 30, so that the temperature of the slurry generated by the reaction When the temperature is 30°C and the pH value is 9.5, the gelation is stopped; the slurry obtained from the reaction is transported to the aging tank through a pipeline that is long enough and has multiple U-shaped bends, and the temperature of the slurry is raised in the aging tank, and the aging temperature is 95°C ; Filter the aged slurry, and wash the filter cake until neutral; dry ...

Embodiment 3

[0037] The sodium metaaluminate solution with an alumina concentration of 35.3g / L is continuously added to the reaction device through a pump, and a mixed gas of air and carbon dioxide is introduced. The volume percentage of carbon dioxide in the mixed gas is 50%, and the pressure of the mixed gas is 0.15MPa, so that the sodium metaaluminate solution forms a strong liquid flow and fully mixes with carbon dioxide gas to produce many and delicate bubbles; control the flow ratio of the mixed gas and sodium metaaluminate solution to 40, so that the temperature of the slurry generated by the reaction When the temperature is 35°C and the pH value is 10, the gelation is stopped; the slurry obtained from the reaction is transported to the aging tank through a pipeline that is long enough and has multiple U-shaped bends, and the temperature of the slurry is raised in the aging tank, and the aging temperature is 100°C ; Filter the aged slurry, and wash the filter cake until neutral; dry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com