Method for blasting and finishing mould

A finishing and mold wall technology, applied in the direction of casting mold, core, casting mold composition, etc., can solve the problems of time-consuming and expensive, and achieve the effect of simplifying production, simplifying manufacturing and finishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

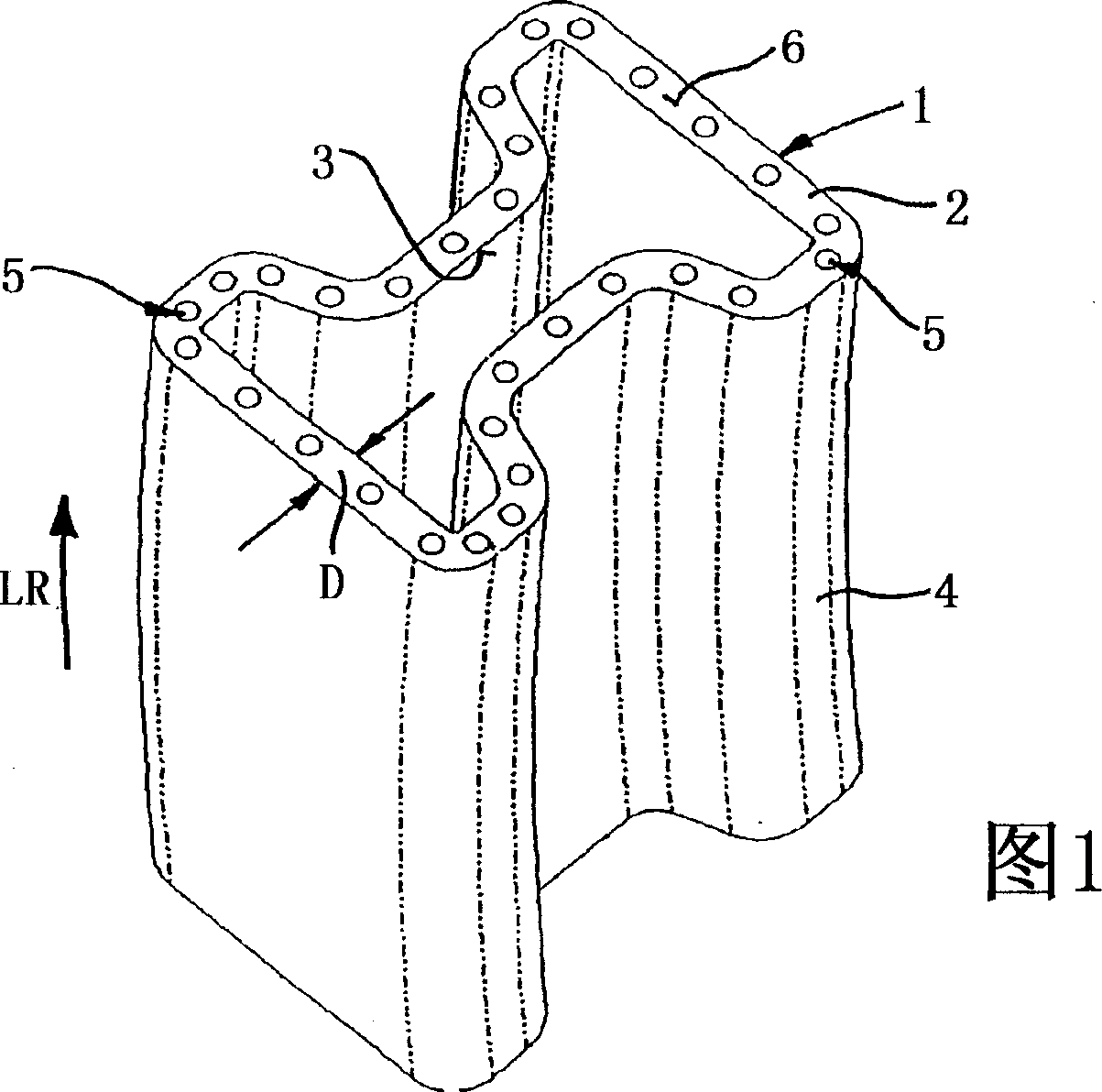

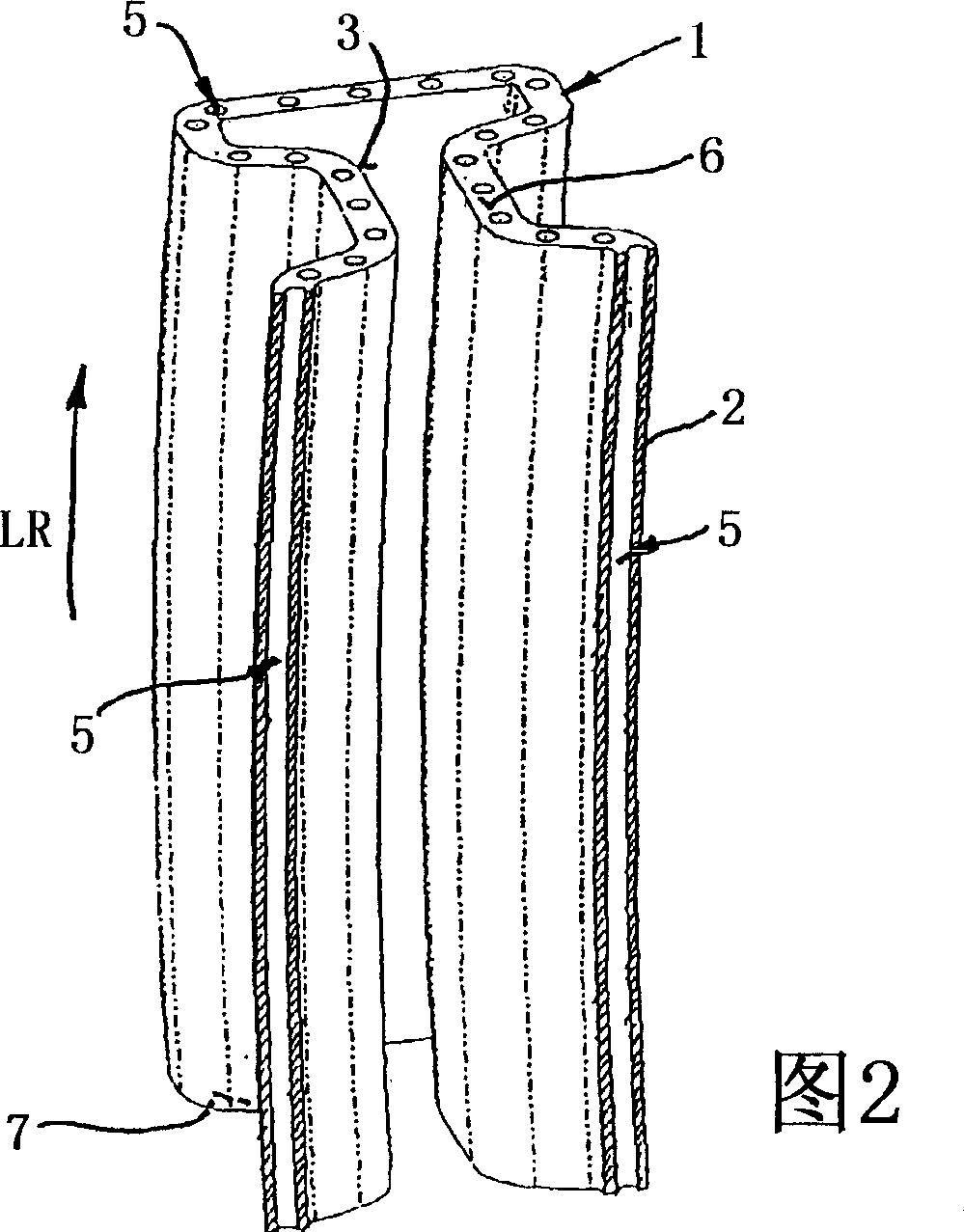

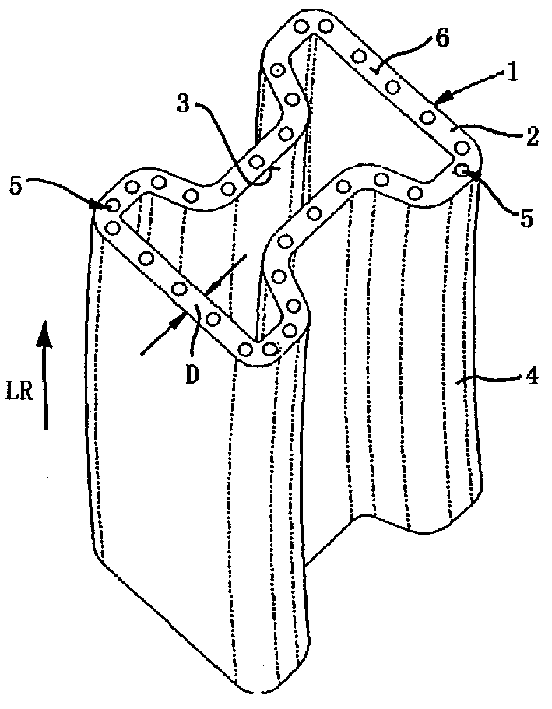

[0020] The tubular form 1 shown in accompanying drawing 1 and accompanying drawing 2 has the cross-section of an I-shaped molding.

[0021] It has a surrounding tubular wall 2 of constant thickness D. The mold given by the inner wall 3 of the tubular form 1 is thus also reflected on the outer surface 4 .

[0022] The holes 5 in the tube wall 2 are distributed along the longitudinal direction of the tube form 1 . The bores 5 run parallel to one another at a distance and emerge from the end faces 6 , 7 of the tube wall 2 . These holes 5 have a circular cross section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com