A method of preparing pseudoboehmite

A pseudo-boehmite and aluminum hydroxide technology, which is applied in the field of preparing pseudo-boehmite, can solve the problems of dispersed aluminum hydroxide particle size distribution, non-concentrated catalyst carrier pore distribution, and unstable product properties. The effect of uniform diameter, uniform properties and stable product properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

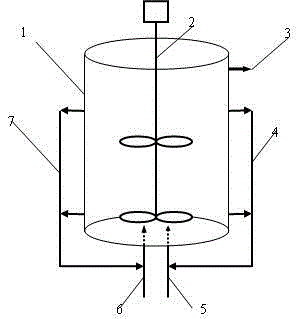

[0036] Adopt the pseudoboehmite prepared by the present invention, the reactor volume is 500mL, and the control material residence time is 15 minutes, and the process is as follows: aluminum sulfate solution (50g Al 2 o 3 / L) and sodium metaaluminate solution (200gAl 2 o 3 / L) At the same time, it enters the reactor from the feed port I 5 and the feed port II 6 at the lower part of the reaction cylinder, and the circulating material passes through the slurry circulation system I 4 and the slurry circulation system II 7 respectively, and the circulation line I 4 is controlled at 10mL / min The circulation volume of the slurry is injected into the acid pipeline, and in the pipeline, it is mixed with the aluminum sulfate solution with a flow rate of 25mL / min and enters the reactor together; similarly, the slurry is injected into the alkali with a circulation volume of 25mL / min by controlling the circulation line II 7 and then mixed with sodium metaaluminate solution with a flow r...

Embodiment 2

[0038] The preparation process is as in Example 1, except that the gelling temperature is controlled at 90°C, the pH value of the mixed slurry is adjusted to 9 with potassium carbonate solution, the aging temperature is 90°C, and the aging time is 30 minutes, then washed and dried at 150°C for 4 hours , the physical and chemical properties of the prepared pseudo-boehmite are shown in Table 1.

Embodiment 3

[0040] The preparation process is as in Example 1, except that the residence time of the material is controlled to be 9 minutes, and the circulation line I is controlled to inject the slurry into the acid pipeline with a circulation rate of 35mL / min, and in the pipeline, the aluminum sulfate solution with a flow rate of 35mL / min After mixing, enter the reactor together; similarly, control the circulation line II 7 to inject the slurry into the alkaline line at a circulation rate of 20mL / min, and enter the reaction together after mixing with the sodium metaaluminate solution with a flow rate of 20mL / min in the line The physical and chemical properties of the prepared pseudo-boehmite are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com