High-strength Fe-Co-Ni-Cr-Mn high-entropy alloy and preparation method thereof

A high-entropy alloy and high-strength technology, applied in the field of high-entropy alloys, can solve problems such as adverse effects on alloy mechanical properties, restrictions on research and development and engineering applications, and difficult processes, so as to achieve good operability and practicability, and eliminate dendrites The effect of uniform organization and composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of a high-strength FeCoNiCrMn high-entropy alloy material adopts a forming method combining mechanical alloying and spark plasma sintering technology, which includes the following steps and process conditions:

[0042] Step 1: Preparation of FeCoNiCrMn high-entropy alloy powder by mechanical alloying method

[0043] Weigh Fe, Co, Ni, Cr, Mn elemental powders respectively according to the atomic ratio of 30%, 17.5%, 17.5%, 17.5%, and 17.5%, and mix them uniformly;

[0044] Put the mixed powder and balls into the ball mill tank of the planetary high-energy ball mill for ball milling. The material of the tank body and the balls are all stainless steel. The ball mill tank is evacuated and filled with high-purity argon (99.99%) as a protective atmosphere;

[0045]With the prolongation of ball milling time, the mixed powder gradually realizes alloying, and the mixed powder of various single powders transforms into the alloy powder with single-phase FCC st...

Embodiment 2

[0056] A preparation method of a high-strength FeCoNiCrMn high-entropy alloy material adopts a forming method combining mechanical alloying and spark plasma sintering technology, which includes the following steps and process conditions:

[0057] Step 1: Preparation of FeCoNiCrMn high-entropy alloy powder by mechanical alloying method

[0058] Weigh Fe, Co, Ni, Cr, Mn elemental powders respectively according to the atomic ratio of 40%, 15%, 15%, 15%, and 15%, and mix them uniformly;

[0059] Put the mixed powder and balls into the ball mill tank of the planetary high-energy ball mill for ball milling. The material of the tank body and the balls are all stainless steel. The ball mill tank is evacuated and filled with high-purity argon (99.99%) as a protective atmosphere;

[0060] With the prolongation of ball milling time, the mixed powder gradually realizes alloying, and the mixed powder of various single powders transforms into the alloy powder with single-phase FCC structure...

Embodiment 3

[0071] A preparation method of a high-strength FeCoNiCrMn high-entropy alloy material adopts a forming method combining mechanical alloying and spark plasma sintering technology, which includes the following steps and process conditions:

[0072] Step 1: Preparation of FeCoNiCrMn high-entropy alloy powder by mechanical alloying method

[0073] Weigh Fe, Co, Ni, Cr, Mn elemental powders respectively according to the atomic ratio of 50%, 12.5%, 12.5%, 12.5%, and 12.5%, and mix them uniformly;

[0074] Put the mixed powder and balls into the ball mill tank of the planetary high-energy ball mill for ball milling. The material of the tank body and the balls are all stainless steel. The ball mill tank is evacuated and filled with high-purity argon (99.99%) as a protective atmosphere;

[0075] With the prolongation of ball milling time, the mixed powder gradually realizes alloying, and the mixed powder of various single powders transforms into the alloy powder with single-phase FCC s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

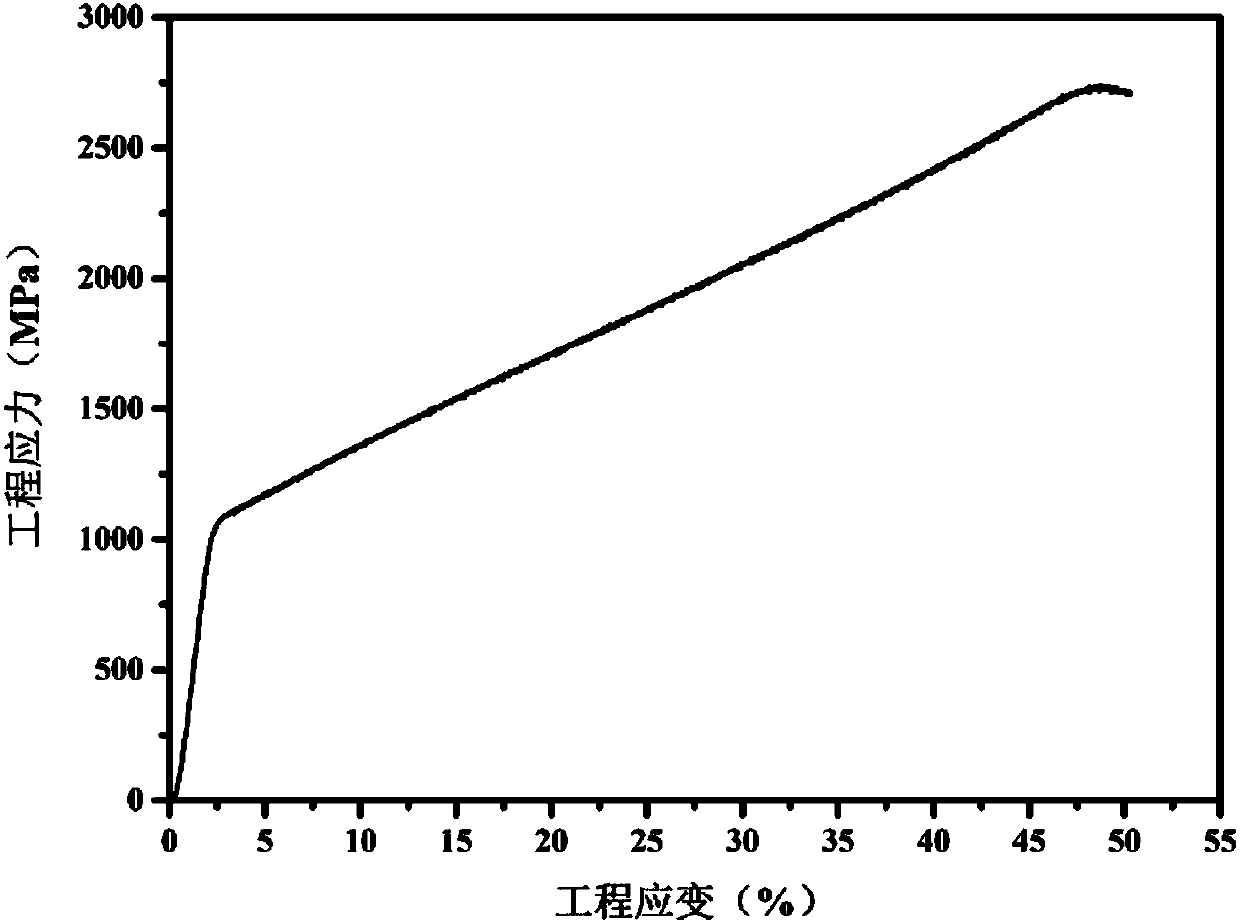

| compressive yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com