Preparation method for CQDs@PVP/PVDF composite dielectric film

A composite dielectric film and composite film technology, which is applied in the field of composite film materials, can solve the problems of unsolved carbon quantum dot dispersion problems, composite material dielectric properties, carbon quantum dots are easy to agglomerate, and increase the breakdown field strength. Achieve the effect of strong repeatability, low cost and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

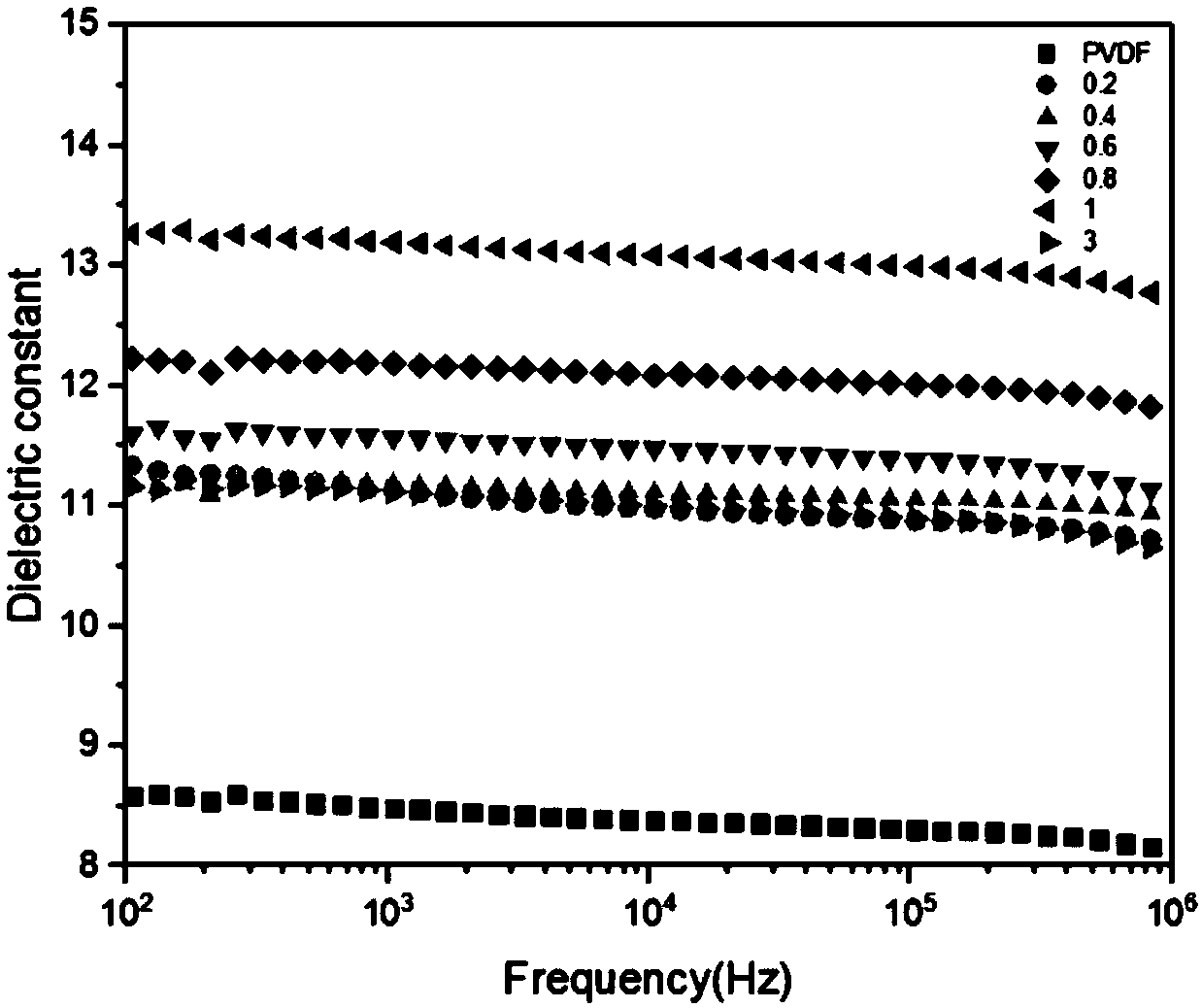

Embodiment 1

[0026] 1) Use a graphite rod as an electrode, insert it into a beaker filled with 700mL of ultrapure water, immerse the graphite rod by 4 cm in the liquid surface, and keep the distance between the two graphite rods by 10 cm, then pass through 60V DC for electrolysis, and electrolyze the electrolyte solution after 7 days Perform high-speed centrifugation at a speed of 10,000 r / min, take the upper layer of light yellow clear liquid, and place it in an electric blast drying oven at 60°C for 8 hours to obtain carbon quantum dot nanoparticles.

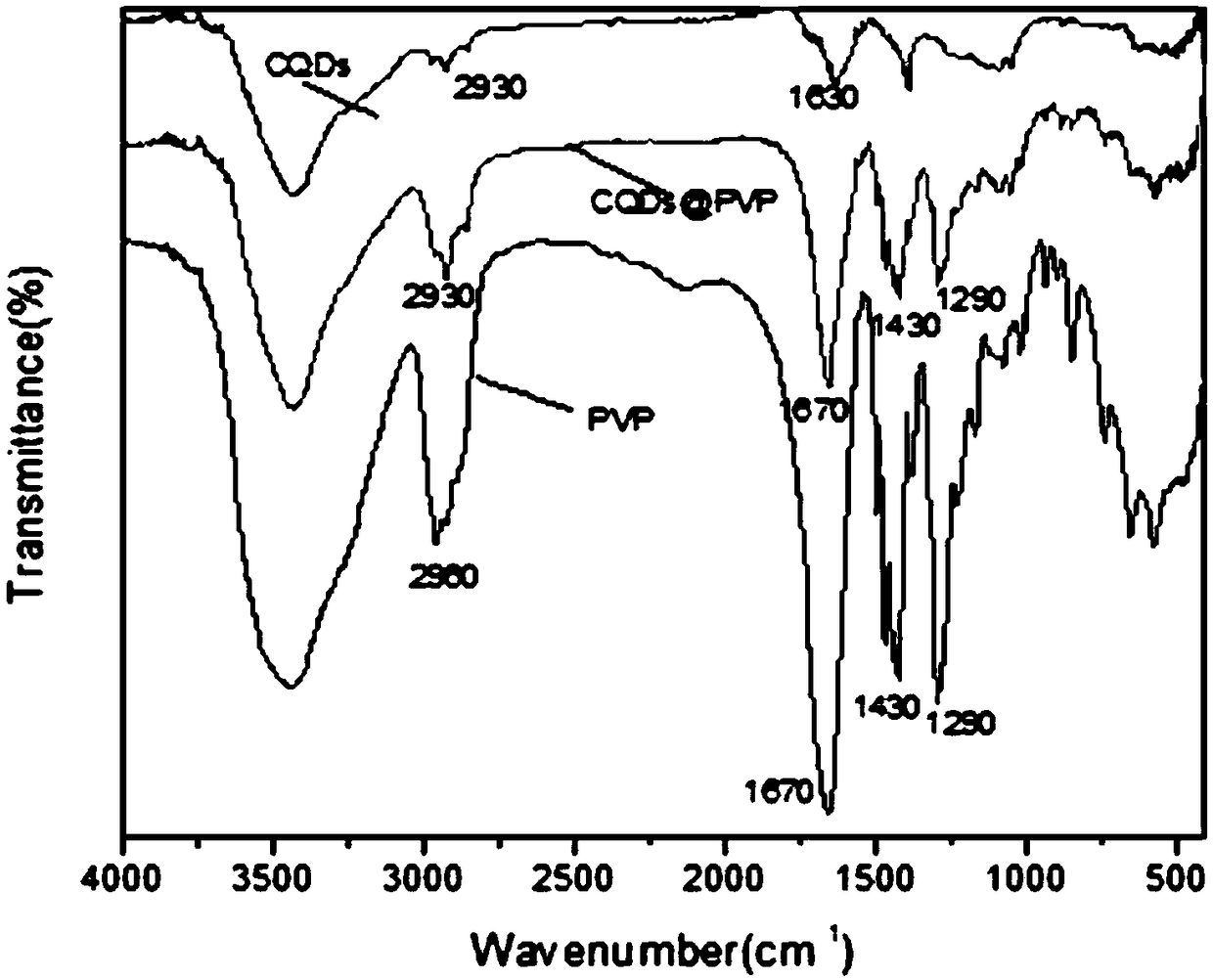

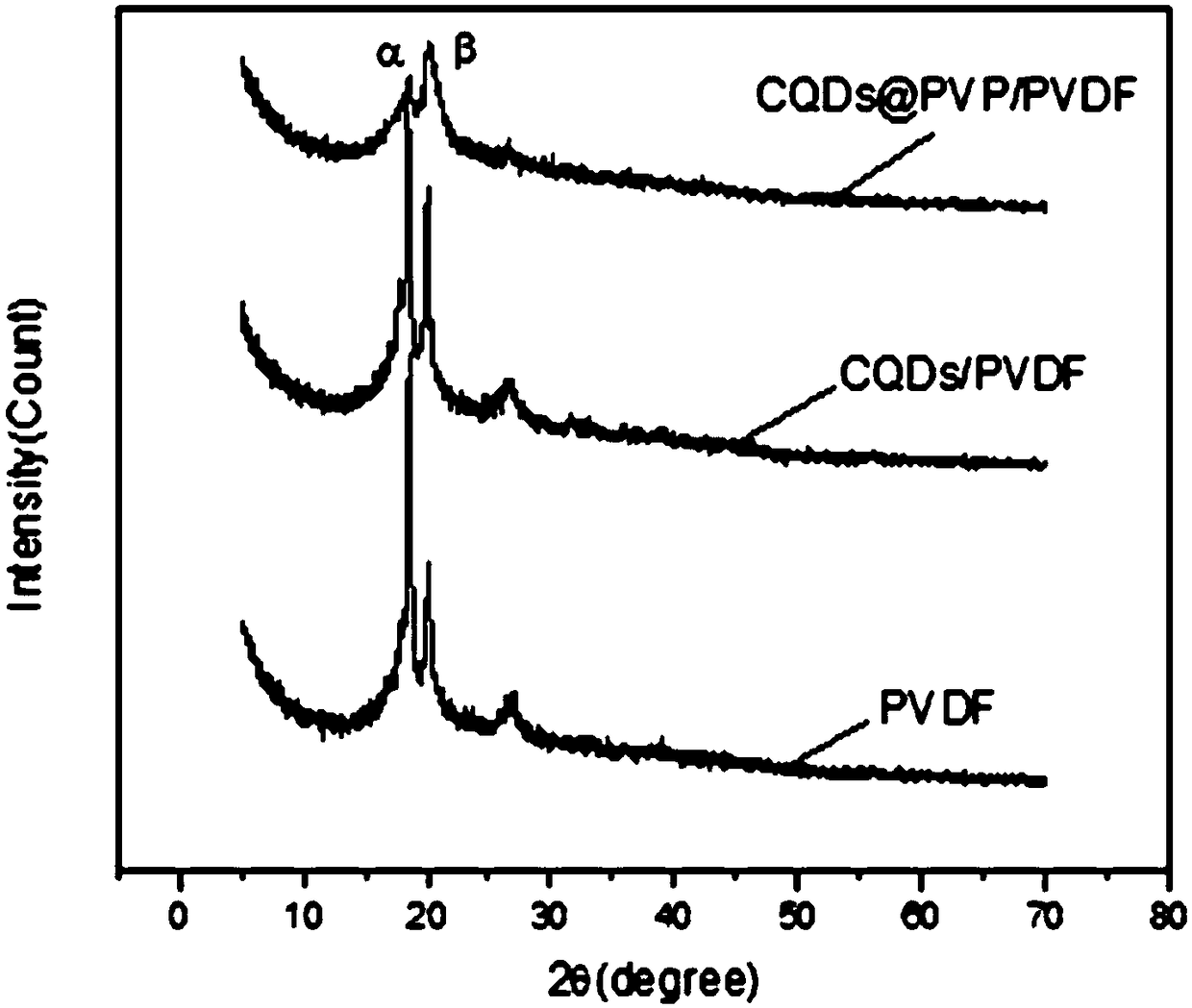

[0027] 2) Weigh 1 g of carbon quantum dots, disperse them in deionized water, stir them magnetically for 2 hours, and then ultrasonically disperse them evenly for 1 hour. Weigh 5g of PVP powder, add it into the carbon quantum dot aqueous solution, and stir magnetically at room temperature for 24 hours. After fully reacting, the solution was centrifuged at 10,000 rpm, and the solid product was washed three times with absolute ethanol, and t...

Embodiment 2

[0034] 1) Use a graphite rod as an electrode, insert it into a beaker filled with 700mL of ultrapure water, immerse the graphite rod by 4 cm in the liquid surface, and keep the distance between the two graphite rods by 10 cm. After 7 days of electrolysis, the electrolyte solution was centrifuged at a speed of 10000r / min at a high speed, and the upper layer of light yellow clear liquid was taken, and it was placed in an electric blast drying oven at 60°C for 12 hours to obtain Carbon quantum dot solid nanoparticles.

[0035] 2) Weigh 1 g of carbon quantum dots, dissolve them in deionized water, stir them magnetically for 2 hours, and then disperse them ultrasonically for 1 hour. Weigh 5g of PVP powder, add it into the carbon quantum dot solution, and stir magnetically at room temperature for 24 hours. After fully reacting, the solution was centrifuged at 10,000 rpm, and the solid product was washed three times with absolute ethanol, and then dried in a constant temperature dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com