Method of preparing high purity Danshensu

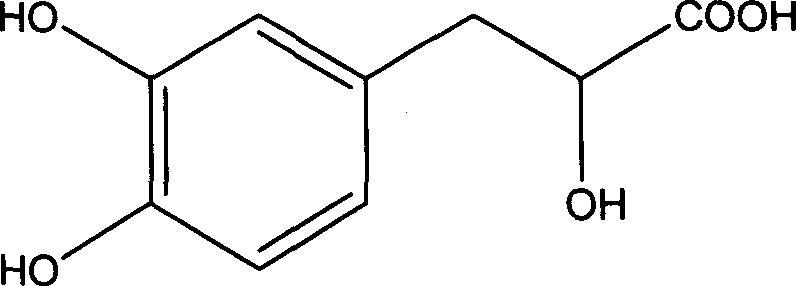

A Danshensu, high-purity technology, applied in the field of preparation of high-purity Danshensu, can solve the problems of poor controllability, low yield, complicated post-processing operation process, etc., and achieves low cost, high product yield, and short production cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Extraction and transformation: Weigh 200g of Salvia miltiorrhiza, heat and extract with 10 times the amount of 3mol / L hydrochloric acid aqueous solution at 75°C for 2 hours, extract twice, combine and filter to obtain the extract.

[0040] 2. Column chromatography separation: Weigh 200g of DM301 macroporous resin, pretreat and pack into a column. Add the extract to the top of the chromatography column, and elute with water after completely entering the column bed, until the effluent is neutral by pH test paper, elute with 30% ethanol for 3 column volumes, and combine this part of the eluate.

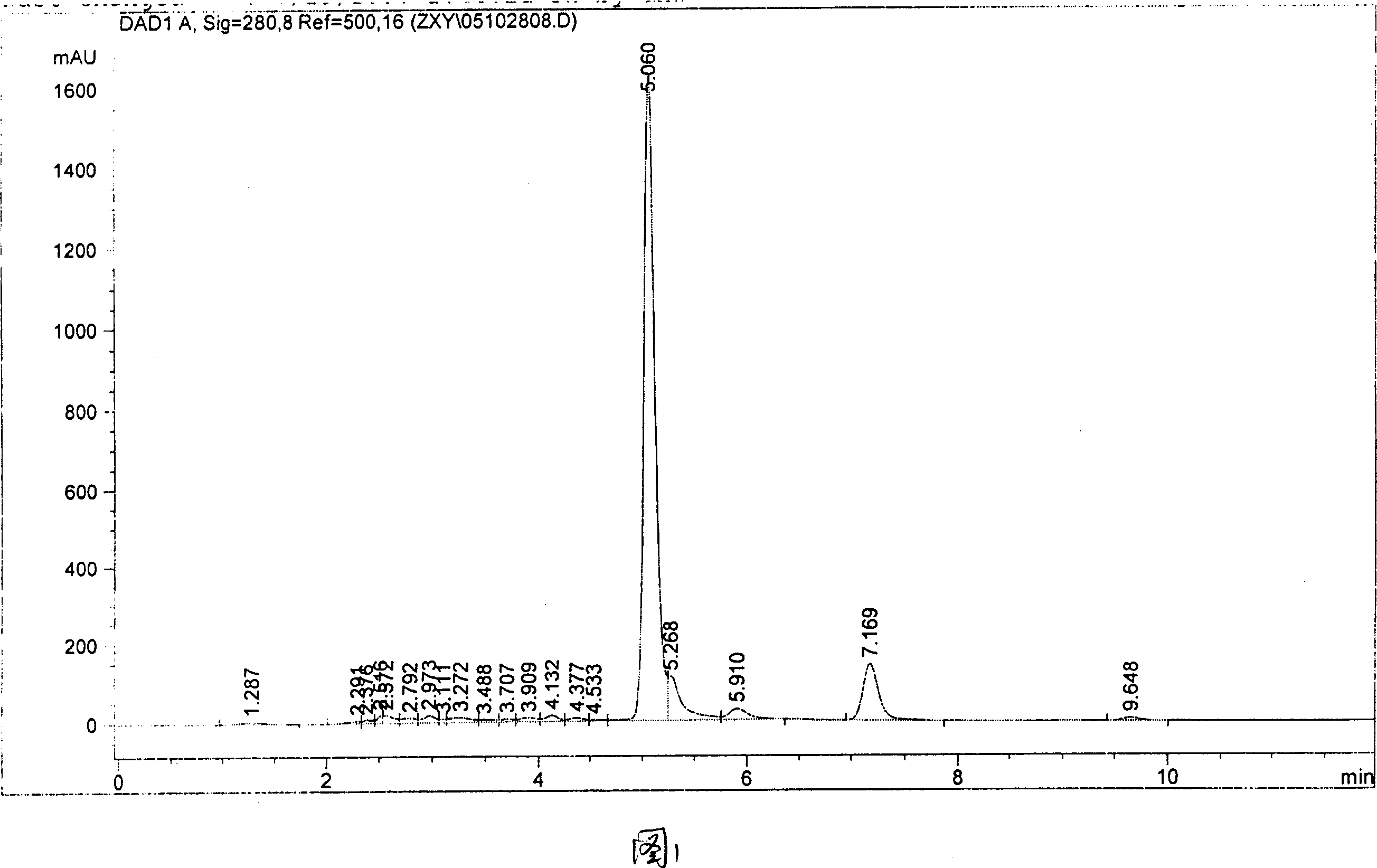

[0041] 3. Recrystallization: The eluent was concentrated under reduced pressure to remove the solvent, heated and dissolved with methanol: acetone 1:1, and left at room temperature to precipitate Danshensu crystals with a yield of 1.8%, and a purity of 92.2% as measured by HPLC.

Embodiment 2

[0043] 1. Extraction and transformation: Weigh 200g of Salvia miltiorrhiza medicinal material, use 8 times the amount of 2mol / L hydrochloric acid 50% ethanol solution, reflux extraction for 2 hours, extract twice, combine and filter to obtain the extract.

[0044] 2. Column chromatography separation: Weigh 200g of 330 type macroporous resin, pretreat and pack into column. Appropriately concentrate the extract to remove ethanol, add it to the top of the chromatography column, and elute with water after completely entering the column bed, until the effluent is neutral by pH test paper, elute with 50% ethanol for 4 column volumes, and combine this part eluent.

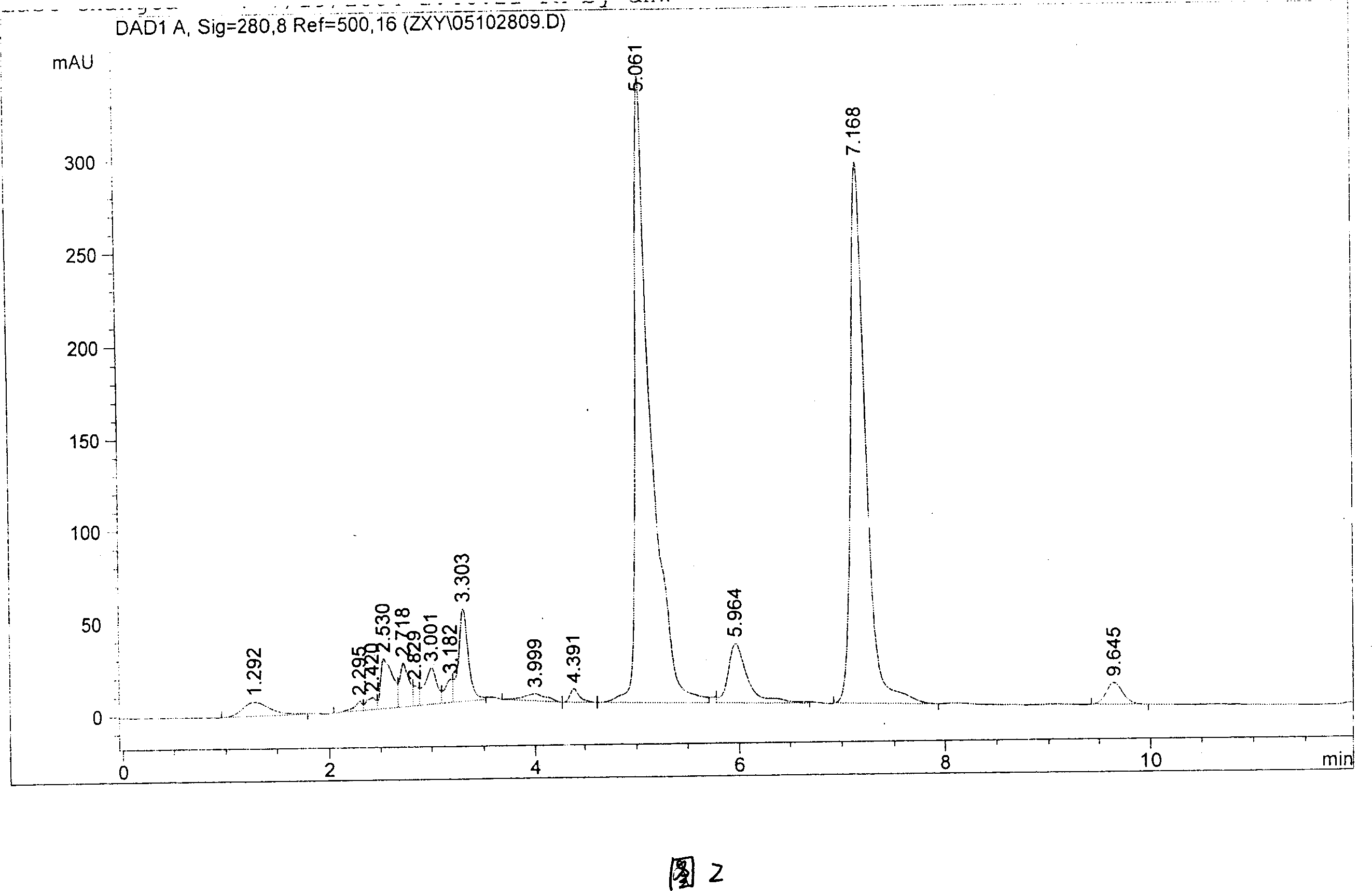

[0045]3. Recrystallization: The eluent was concentrated under reduced pressure to remove the solvent, heated and dissolved with water: ethanol 4:1, and left at 2°C to precipitate Danshensu crystals with a yield of 2.0% and a purity of 91.6% as measured by HPLC.

Embodiment 3

[0047] 1. Extraction and transformation: Weigh 500 g of Danshen medicinal material, reflux extraction with 8 times the amount of 0.1 mol / L sulfuric acid 50% methanol solution for 2 hours, extract twice, combine and filter to obtain the extract.

[0048] 2. Column chromatography separation: Weigh 500g of NKA-II type macroporous resin, pretreat and pack into column. Properly concentrate the extract to remove methanol, add it to the top of the chromatography column, and elute with water after completely entering the column bed, until the effluent is neutral by pH test paper, elute with 50% acetonitrile for 5 column volumes, and combine the parts eluent.

[0049] 3. Recrystallization: The eluate was concentrated under reduced pressure to remove the solvent, heated and dissolved with acetonitrile: acetone 1:4, and placed at -10°C to precipitate Danshensu crystals with a yield of 2.1%, and a purity of 90.9% as measured by HPLC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com