Preparation method of molybdenum boride powder

A molybdenum boride and powder technology is applied in the field of preparation of new materials to achieve the effect of accelerating the reaction rate, improving the purity and realizing the crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

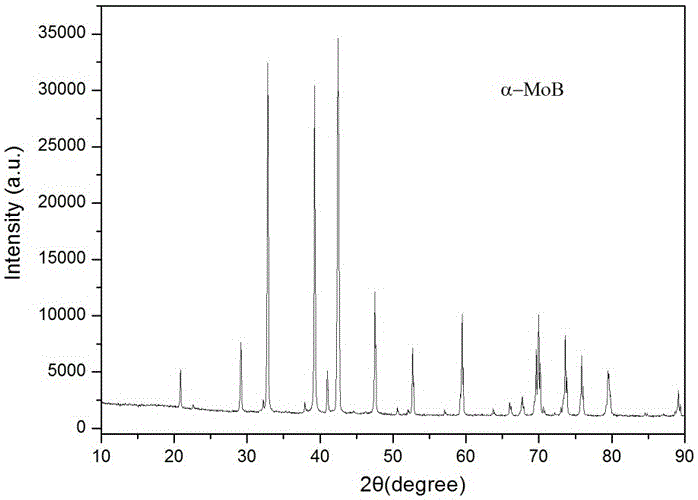

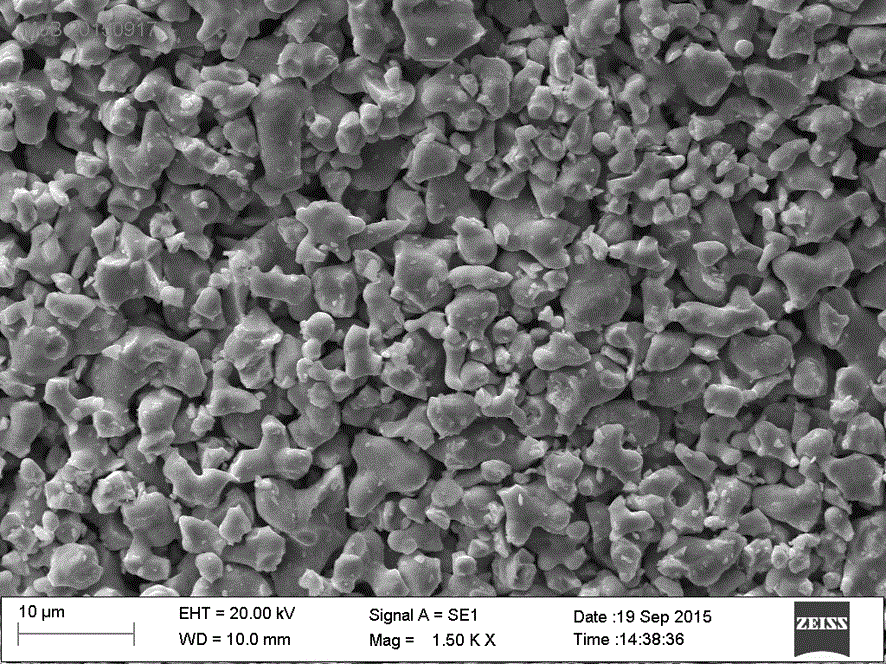

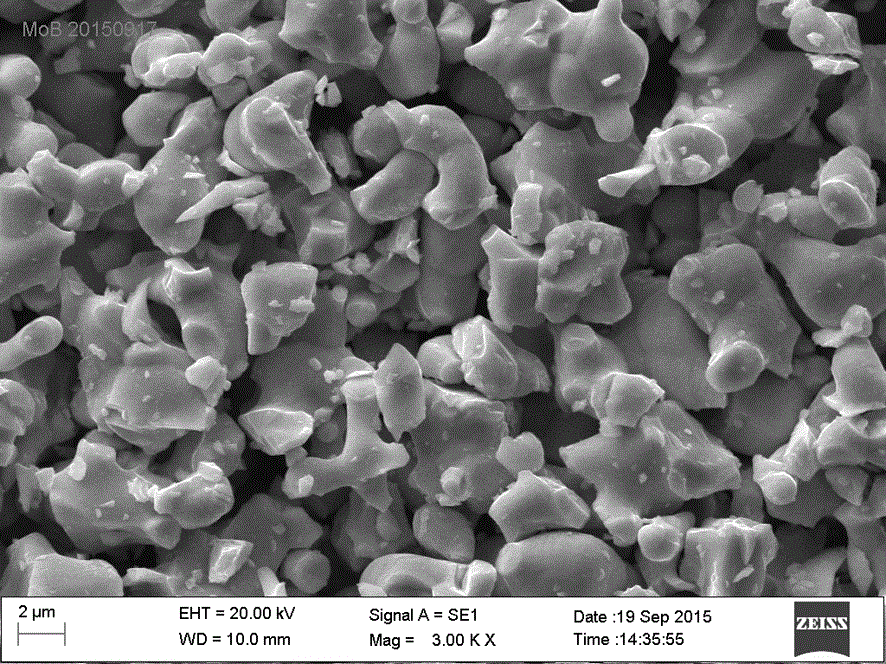

[0026] A preparation method of a new type of molybdenum boride powder material. This preparation method uses high temperature and high pressure to synthesize molybdenum boride powder for the first time. No similar synthesis method has been found in the current patents, reports, papers and other documents. Its specific preparation method comprises the following steps:

[0027] Step 1. First place B powder and Mo powder in graphite crucible and metal molybdenum crucible coated with BN powder on the inner wall, and use hydrogen reduction furnace for reduction. The reduction temperature of boron powder is 1000-1500 °C, and the reduction temperature of molybdenum powder 600-1200℃;

[0028] Step 2: Put the reduced B powder and Mo powder into the ball mill mixing tank for 2-96 hours according to the molar ratio of 0.5 or 1 or 2 or 2.5 or 4, wherein the ball milling medium is edible alcohol, Both the ball milling jar and balls are made of polytetrafluoroethylene;

[0029] Step 3. Po...

Embodiment 1

[0033] (1) First place the B powder and Mo powder in the graphite crucible and the metal molybdenum crucible coated with BN powder on the inner wall respectively, and use a hydrogen reduction furnace for reduction. The reduction temperature of the boron powder is 1200 ° C, and the reduction temperature of the molybdenum powder is 1050 ° C. ℃;

[0034] (2) Put the reduced B powder and Mo powder into the ball mill mixing tank according to the molar ratio of 1:1, and ball mill them for 48 hours. The ball milling medium is edible alcohol. The material of vinyl fluoride;

[0035] (3) Pour the ball-milled mixture into a stainless steel tray, and then place it in a vacuum drying oven for drying at a drying temperature of 100°C;

[0036] (4) Transfer the dried material in step 3 to a graphite crucible coated with BN powder on the inner wall, then place the graphite crucible in a high-temperature and high-pressure container, and control the pressure in the container to 20 GPa at 3 °C ...

Embodiment 2

[0039] (1) First place the B powder and Mo powder in the graphite crucible and the metal molybdenum crucible coated with BN powder on the inner wall respectively, and use a hydrogen reduction furnace for reduction. The reduction temperature of the boron powder is 1200 ° C, and the reduction temperature of the molybdenum powder is 1050 ° C. ℃;

[0040] (2) Put the reduced B powder and Mo powder into the ball mill mixing tank according to the molar ratio of 1:1, and ball mill them for 48 hours. The ball milling medium is edible alcohol. The material of vinyl fluoride;

[0041] (3) Pour the ball-milled mixture into a stainless steel tray, and then place it in a vacuum drying oven for drying at a drying temperature of 100°C;

[0042] (4) Transfer the dried material in step 3 to a graphite crucible coated with BN powder on the inner wall, then place the graphite crucible in a high-temperature and high-pressure container, and control the pressure in the container to 28 GPa at 3 °C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com