Oxygen reduction catalyst including pyrryl tetrazine ring and preparation method of oxygen reduction catalyst

A technology of pyrrolyl tetrazine epoxy and pyrrolyl tetrazine ring, which is applied in the field of fuel cell science, can solve the problems of unfavorable catalyst industrial preparation, complex catalyst preparation methods, and difficult control of preparation process conditions, etc., so as to facilitate diffusion transfer , Excellent methanol resistance, good ORR catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

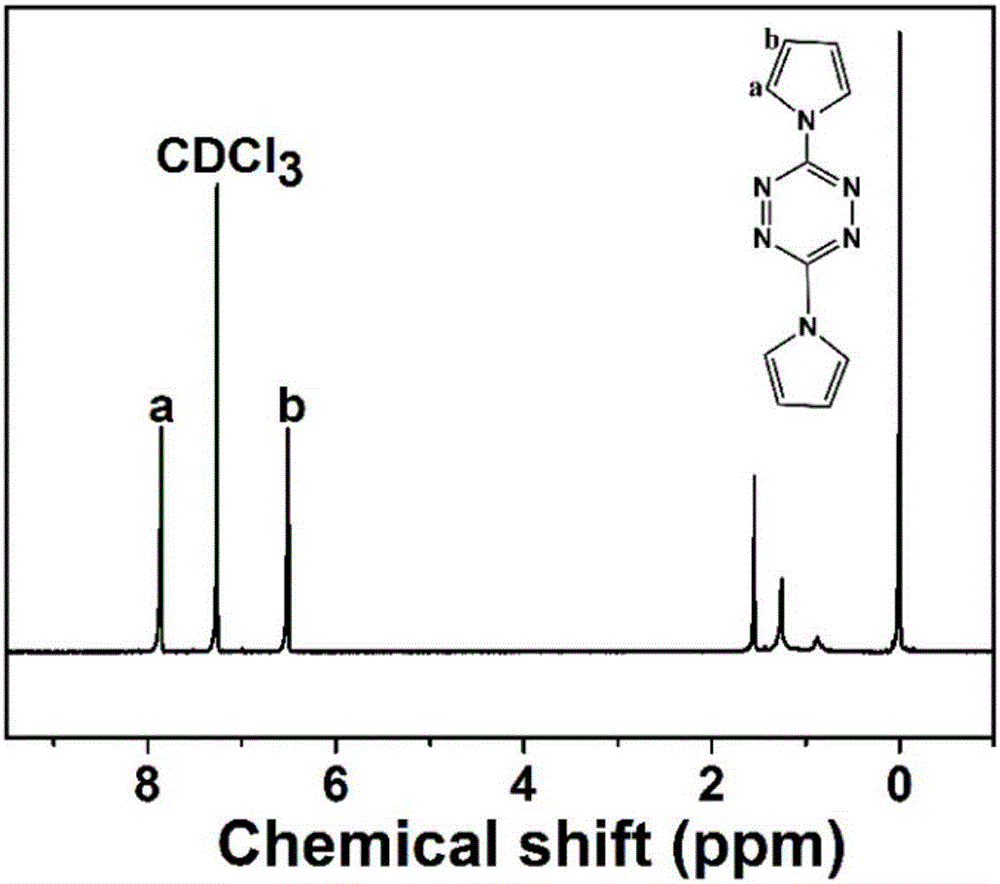

[0047] Example 1 Synthesis of 3,6-bis(pyrrolyl)-1,2,4,5-tetrazine monomer

[0048] Dissolve 1.18 g of pyrrole in 20 mL of dry tetrahydrofuran, add 1.56 g of KOH, and stir for 30 min below 0°C. In addition, the tetrahydrofuran solution containing 3,6-bis(3,5-dimethylpyrazolyl)-1,2,4,5-tetrazine was slowly added dropwise to the above-mentioned pyrrole salt solution, and reacted at room temperature for 1 hour, and then Reflux overnight. Then use petroleum ether and ethyl acetate (12:1) to pass the column, and vacuum dry to constant weight for use. Monomer 3,6-(dipyrrolyl)-1,2,4,5-tetrazine 1 H NMR chart such as figure 1 Shown.

[0049] The reaction of Example 1 is as follows:

[0050]

Embodiment 2

[0051] Example 2 Preparation of oxygen reduction catalyst containing pyrrolyl tetrazine ring

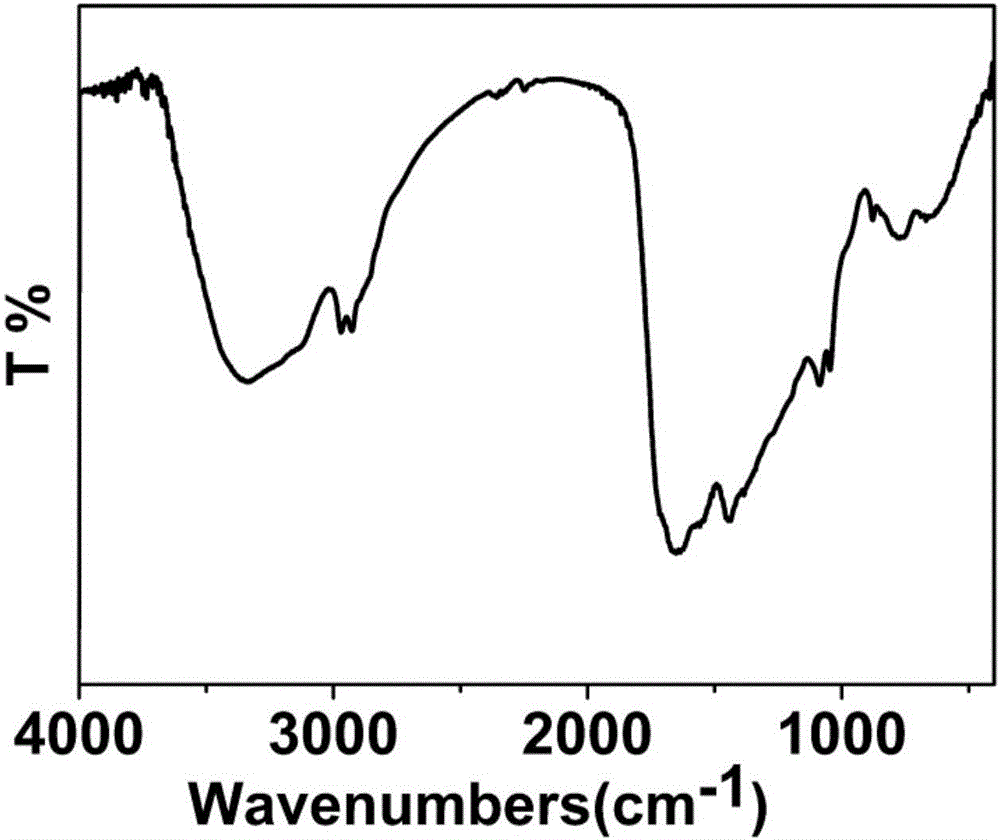

[0052] 1) Synthesis of poly(3,6-dipyrrole-1,2,4,5-tetrazine): 127.2mg of 3,6-bis(pyrrolyl)-1,2,4,5-tetrazine (DPT ) Dissolve in 25mL of 1,2-dichloroethane, add 186.4mg of dimethoxymethane, and finally add 393.9mg of FeCl 3 , React at 45°C for 5h, 80°C for 19h, settle with methanol, wash with methanol several times, finally Soxhlet extraction for 48h, vacuum dry to constant weight. The infrared spectrum of poly(3,6-dipyrrole-1,2,4,5-tetrazine) is as follows figure 2 Shown.

[0053] The synthetic route of poly(3,6-dipyrrole-1,2,4,5-tetrazine) is shown below:

[0054]

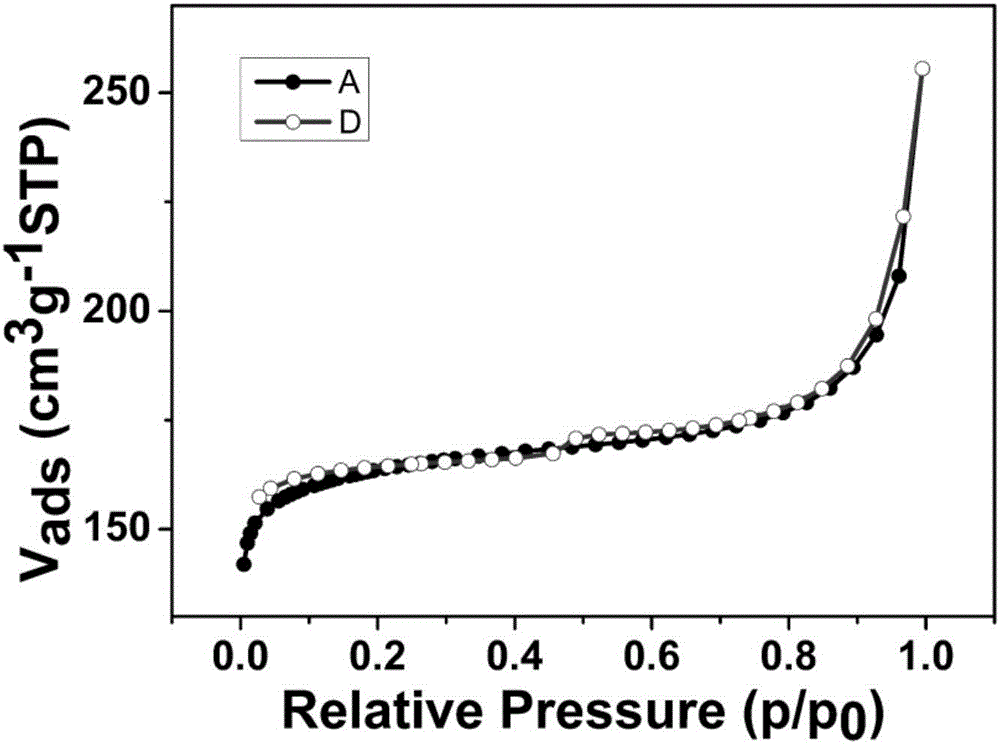

[0055] 2) Preparation of oxygen reduction catalyst containing pyrrolyl tetrazine ring: Take 30 mg of the poly(3,6-dipyrrole-1,2,4,5-tetrazine) prepared in step 1) into a porcelain crucible and place it in a tube In the furnace. Under nitrogen atmosphere, from room temperature to 4℃min -1 The heating rate is increased to 900...

Embodiment 3

[0058] 1) Synthesis of poly(3,6-dipyrrole-1,2,4,5-tetrazine): 127.2 mg of 3,6-bis(pyrrolyl)-1,2,4,5-tetrazine (DPT ) Dissolve in 35mL of 1,2-dichloroethane, then add 364.8mg of dimethoxymethane, and finally add 777.6mg of FeCl 3 , React at 30°C for 4h, 90°C for 24h, settle with ethanol, wash with ethanol several times, finally Soxhlet extraction for 24h, and vacuum dry to constant weight.

[0059] 2) Preparation of oxygen reduction catalyst containing pyrrolyl tetrazine ring: Take 30 mg of the poly(3,6-dipyrrole-1,2,4,5-tetrazine) prepared in step 1) into a porcelain crucible and place it in a tube In the furnace. Under nitrogen atmosphere, from room temperature to 5℃min -1 The heating rate is increased to 1000℃, after 1h of constant temperature, and then at 5℃min -1 The temperature drop rate is cooled to room temperature, and the nitrogen-doped carbon material oxygen reduction catalyst containing pyrrolyl tetrazine ring is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com