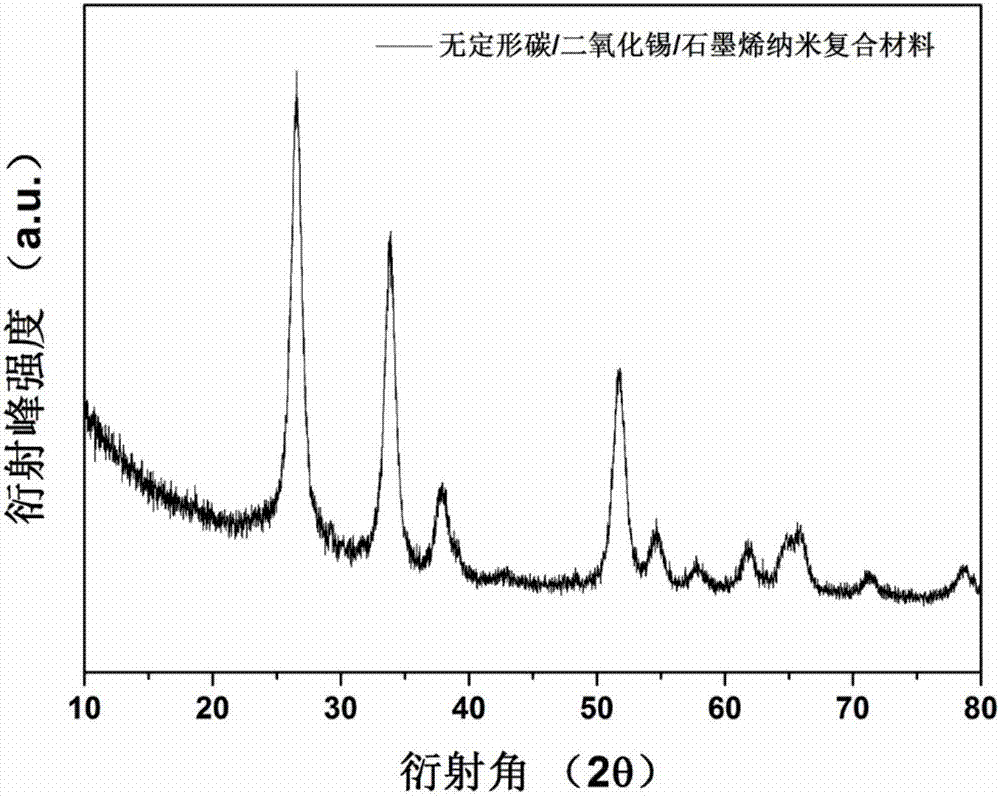

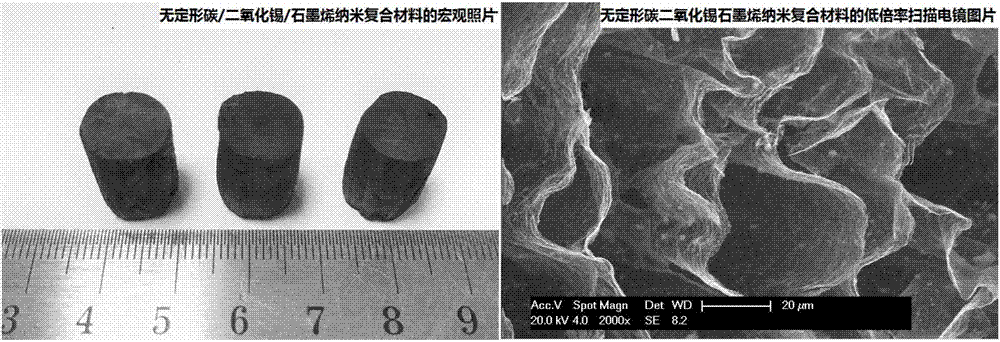

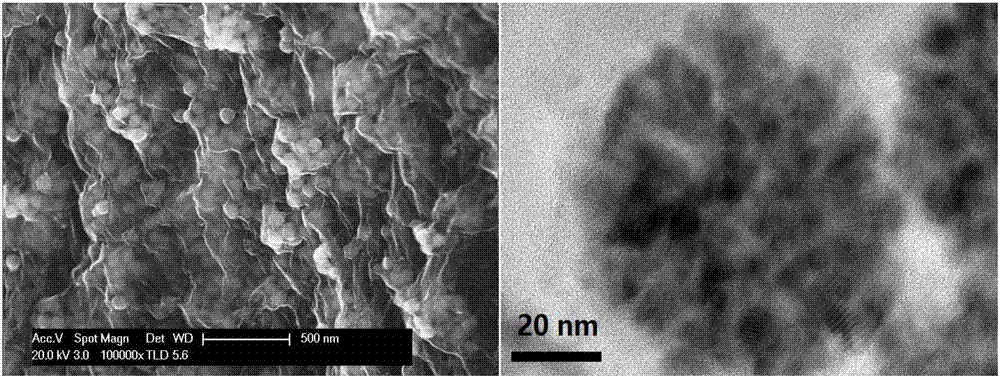

Method for preparing lithium-ion battery negative electrode material with three-dimensional porous structure

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, nanotechnology for materials and surface science, negative electrodes, etc., can solve the problems of rapid capacity decay of tin dioxide and improve cycle stability and rate performance , the effect of shortening the diffusion distance and alleviating the volume change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 8.87g of glucose and 3.93g of potassium stannate were sequentially added to a container containing 70mL of deionized water, and then the above mixed solution was stirred for 1 hour. The mass ratio of glucose and potassium stannate was 2.25:1. The obtained colorless solution was put into a hydrothermal reaction kettle, sealed, and the reaction kettle was placed in a drying oven at 180° C. to heat for 4 hours. After the reaction, the product was centrifuged, the supernatant was discarded, and the precipitate was thoroughly cleaned, and the obtained brown solid (tin dioxide / polysaccharide) was dried in a vacuum oven at 80°C for 12 hours;

[0025] Add 100 mg of tin dioxide / polysaccharide into a container containing 10 mL of a mixed solution of water and ethanol, and sonicate for 1 hour, wherein the volume ratio of water and ethanol is 1:1. Then add 17.5 mg of sodium carboxymethyl cellulose and 25 mg of polyvinyl alcohol to the above solution successively, and stir for 10 mi...

Embodiment 2

[0033]The glucose of 7.86g and the potassium stannate of 3.93g are added successively in the container that fills 80mL deionized water, then above-mentioned mixed solution is stirred 1.5 hours, and the mass ratio of glucose and potassium stannate is 2:1; Will obtain Put the colorless solution into a hydrothermal reaction kettle, seal it, and heat the reaction kettle in a drying oven at 170°C for 6 hours; centrifuge the product after the reaction is completed, pour off the supernatant, and clean the precipitate thoroughly , place the obtained tan solid (tin dioxide / polysaccharide) in a vacuum oven at 70°C and dry for 10 hours;

[0034] Add 200mg of tin dioxide / polysaccharide to a container containing 20mL of a mixed solution of water and ethanol, ultrasonicate for 1.5 hours, wherein the volume ratio of water and ethanol is 3:2; then add 20mg to the above solution in sequence Add sodium carboxymethyl cellulose and 28.6mg polyvinyl alcohol, stir for 20 minutes, the mass ratio of ...

Embodiment 3

[0037] The glucose of 11.79g and the potassium stannate of 3.93g are added successively in the container that fills 80mL deionized water, then above-mentioned mixed solution is stirred 0.5 hour, and the mass ratio of glucose and potassium stannate is 3:1; The obtained Put the colorless solution into a hydrothermal reaction kettle, seal it, and heat the reaction kettle in a drying oven at 160°C for 8 hours; centrifuge the product after the reaction is complete, pour off the supernatant, and clean the precipitate thoroughly , place the obtained tan solid (tin dioxide / polysaccharide) in a vacuum drying oven at 60°C for 8 hours;

[0038] Add 50 mg of tin dioxide / polysaccharide to a container containing 15 mL of a mixed solution of water and ethanol, and ultrasonicate for 1.5 hours, wherein the volume ratio of water and ethanol is 2:3; then add 15 mg to the above solution in sequence Add sodium carboxymethyl cellulose and 21.4 mg polyvinyl alcohol, stir for 20 minutes, the mass rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com