Chocolate coconut roll and preparation method thereof

A coconut-flavored roll and chocolate technology, which is applied in the food field, can solve problems such as unreasonable production technology, insufficient nutrition, and single taste, and achieve the effects of not being easy to break, simple preparation method, and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

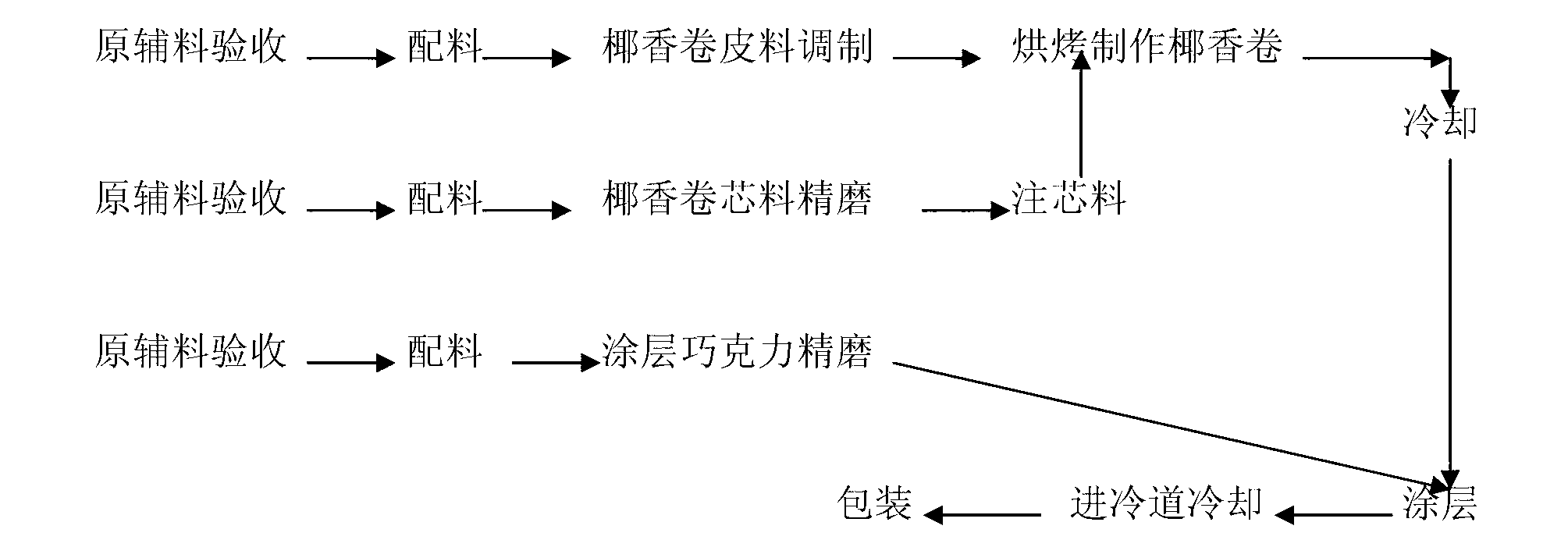

Method used

Image

Examples

Embodiment 1

[0028] The chocolate coconut roll comprises an egg roll, a core material filled in the egg roll and a chocolate coating coated on the outside of the egg roll, and the mass ratio of the egg roll, the core material and the chocolate coating is 38:34:24.

[0029] The egg roll is made of the following components by weight: 60-65 parts of wheat flour, 25-30 parts of white sugar powder, 4-6 parts of salad oil, 1-3 parts of water, 0.5-1 part of phospholipid oil, 0.5 parts of egg -1 part, 0.1-0.3 part of refined salt, 0.01-0.10 part of β-carotene;

[0030] The core material is made of the following components by weight: 35-45 parts of anhydrous margarine, 15-25 parts of white sugar powder, 15-20 parts of whole milk powder, 10-15 parts of whey powder, 5 parts of coconut powder -10 parts, 0.3-0.8 parts of lecithin, 0.1-0.2 parts of roasted coconut essence, 0.1-0.2 parts of refined salt, 0.01-0.10 parts of vanillin, 0.01-0.10 parts of ethyl maltol;

[0031] The chocolate coating is made...

Embodiment 2

[0058] The chocolate coconut roll comprises an egg roll, a core material filled in the egg roll and a chocolate coating coated on the outside of the egg roll, and the mass ratio of the egg roll, the core material and the chocolate coating is 40:36:28.

[0059] Chocolate coconut rolls, the egg rolls are made of the following components by weight: 60-65 parts of wheat flour, 25-30 parts of white sugar powder, 4-6 parts of salad oil, 1-3 parts of water, 0.5-30 parts of phospholipid oil 1 part, 0.5-1 part of egg, 0.1-0.3 part of refined salt, 0.01-0.10 part of β-carotene;

[0060] The core material is made of the following components by weight: 35-45 parts of anhydrous margarine, 15-25 parts of white sugar powder, 15-20 parts of whole milk powder, 10-15 parts of whey powder, 5 parts of coconut powder -10 parts, 0.3-0.8 parts of lecithin, 0.1-0.2 parts of roasted coconut essence, 0.1-0.2 parts of refined salt, 0.01-0.10 parts of vanillin, 0.01-0.10 parts of ethyl maltol;

[0061] ...

Embodiment 3

[0089] The chocolate coconut roll comprises an egg roll, a core material filled in the egg roll and a chocolate coating coated on the outside of the egg roll, and the mass ratio of the egg roll, the core material and the chocolate coating is 39:35:26.

[0090] Chocolate coconut rolls, the egg rolls are made of the following components by weight: 61.8 parts of wheat flour, 29.3 parts of white granulated sugar, 5.1 parts of salad oil, 2.0 parts of water, 0.76 parts of lecithin oil, 0.63 parts of eggs, and 0.16 parts of refined salt , 0.06 parts of β-carotene;

[0091] The core material is made of the following components by weight: 40.1 parts of anhydrous margarine, 21.4 parts of white sugar powder, 16.1 parts of whole milk powder, 13.2 parts of whey powder, 8.3 parts of coconut powder, 0.52 parts of lecithin, roasted 0.13 parts of coconut essence, 0.12 parts of refined salt, 0.04 parts of vanillin, 0.026 parts of ethyl maltol;

[0092] The chocolate coating is made of the foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com