Old oil hotpot flavor essential oil and preparation method thereof

A technology for hot pot and monosodium glutamate, which is applied to the field of old oil hot pot flavor essential oil and its preparation, can solve the problems of low production cost, need to be used in large quantities or repeated many times for cooking, stewing and frying, and no patent publication documents have been found, and achieves reduction of production cost and simple method. , the effect of natural flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

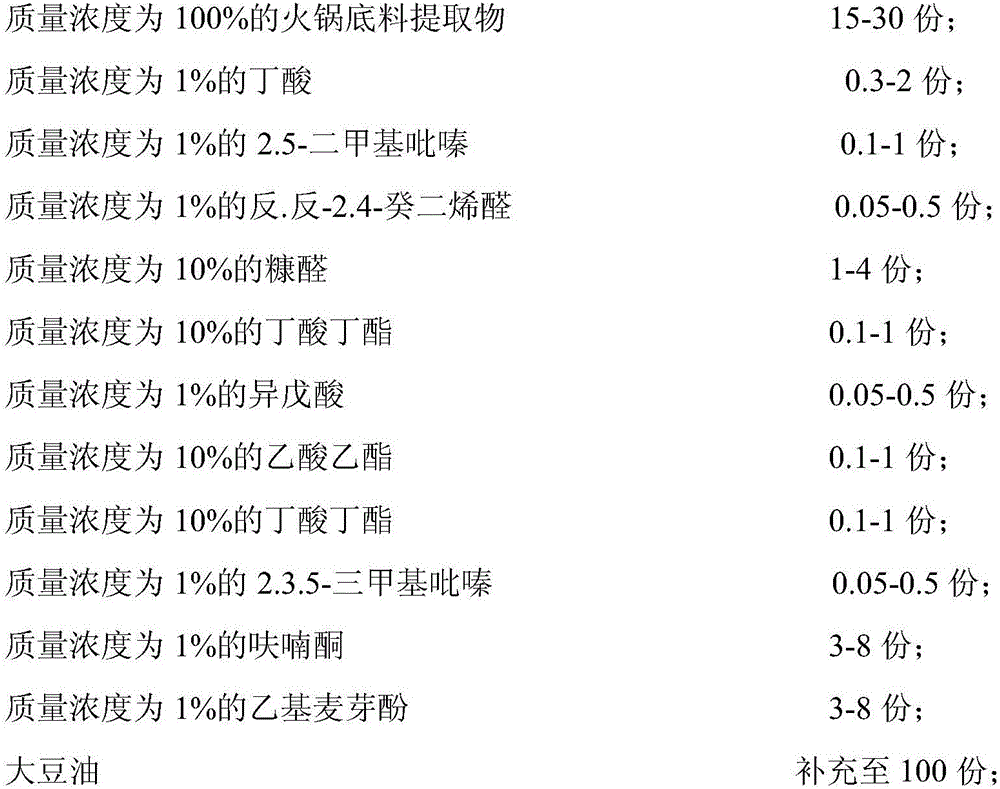

[0039] A kind of old oil chafing dish flavor essential oil, its composition and parts by weight are as follows:

[0040]

[0041] Among them, the butyric acid, 2.5-dimethylpyrazine, trans. trans-2.4-decadienal, furfural, butyl butyrate, isovaleric acid, ethyl acetate, butyl butyrate, 2.3.5- The solvents of trimethylpyrazine, furanone and ethyl maltol are soybean oil.

[0042] Wherein, the soybean oil is first grade soybean oil.

[0043] The composition and parts by weight of the above-mentioned hot pot fresh oil are as follows:

[0044] 720 parts of rapeseed oil, 80 parts of butter, 50 parts of onion, 25 parts of ginger, 75 parts of dried chili, 14 parts of crushed peppercorns, 80 parts of Pixian watercress, 15 parts of tempeh, 0.6 parts of cloves, 2.0 parts of cinnamon, grass 1.0 parts of crushed fruit, 0.4 parts of crushed bay leaves, 1.8 parts of crushed fennel, 3 parts of crushed star anise, 0.85 parts of crushed grass, 2 parts of crushed Sanai, 20 parts of cooking wi...

Embodiment 2

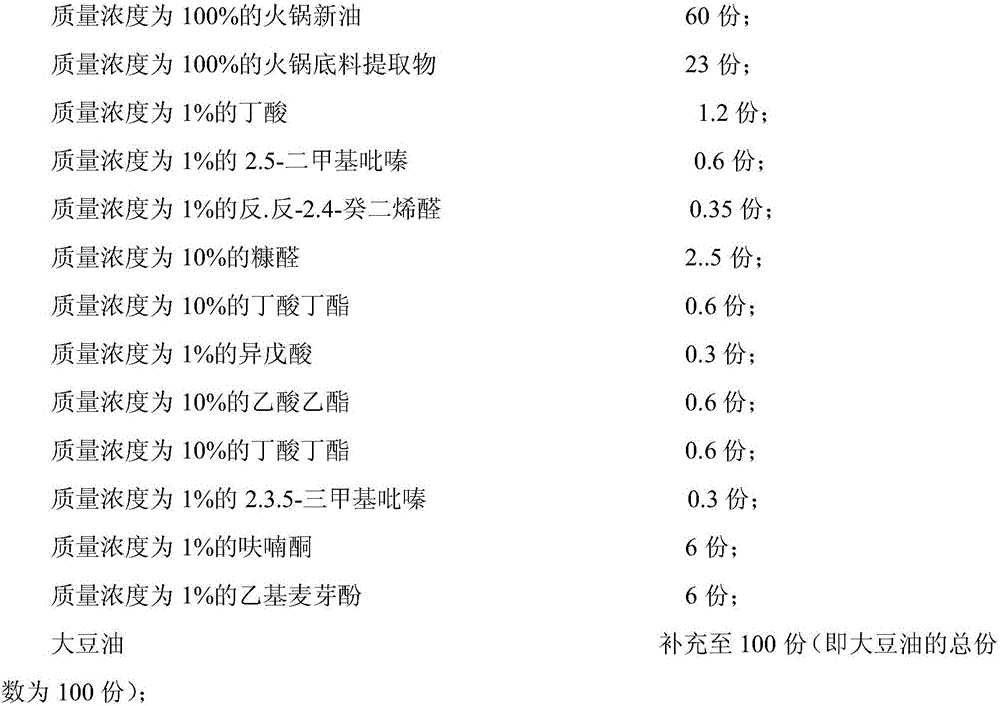

[0062] A kind of old oil chafing dish flavor essential oil, its composition and parts by weight are as follows:

[0063]

[0064]

[0065] Among them, the butyric acid, 2.5-dimethylpyrazine, trans. trans-2.4-decadienal, furfural, butyl butyrate, isovaleric acid, ethyl acetate, butyl butyrate, 2.3.5- The solvents of trimethylpyrazine, furanone and ethyl maltol are soybean oil.

[0066] The composition and parts by weight of the new chafing dish oil are as follows:

[0067] 600 parts of rapeseed oil, 60 parts of butter, 30 parts of onion, 10 parts of ginger, 30 parts of dried chili, 5 parts of crushed peppercorns, 50 parts of Pixian watercress, 5 parts of tempeh, 0.1 parts of cloves, 0.5 parts of cinnamon, 0.5 part of crushed grass fruit, 0.1 part of crushed bay leaf, 1 part of crushed fennel, 1 part of crushed star anise, 0.2 part of crushed grass, 1 part of crushed Sanai, 10 parts of cooking wine, and 10 parts of rock sugar.

[0068] The preparation method of described...

Embodiment 3

[0085] A kind of old oil chafing dish flavor essential oil, its composition and parts by weight are as follows:

[0086]

[0087]

[0088] Among them, the butyric acid, 2.5-dimethylpyrazine, trans. trans-2.4-decadienal, furfural, butyl butyrate, isovaleric acid, ethyl acetate, butyl butyrate, 2.3.5- The solvents of trimethylpyrazine, furanone and ethyl maltol are soybean oil.

[0089] The soybean oil is first grade soybean oil.

[0090] The composition and parts by weight of the new chafing dish oil are as follows:

[0091] 800 parts of rapeseed oil, 100 parts of butter, 60 parts of green onion, 40 parts of ginger, 90 parts of dried chili, 30 parts of crushed peppercorns, 100 parts of Pixian watercress, 30 parts of tempeh, 3 parts of crushed cloves, 5 parts of crushed cinnamon, grass 5 parts of crushed fruit, 1 part of crushed bay leaf, 10 parts of crushed fennel, 10 parts of crushed star anise, 2 parts of crushed grass, 10 parts of crushed Sannai, 50 parts of cooking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com