Dust suppressant and preparing method thereof

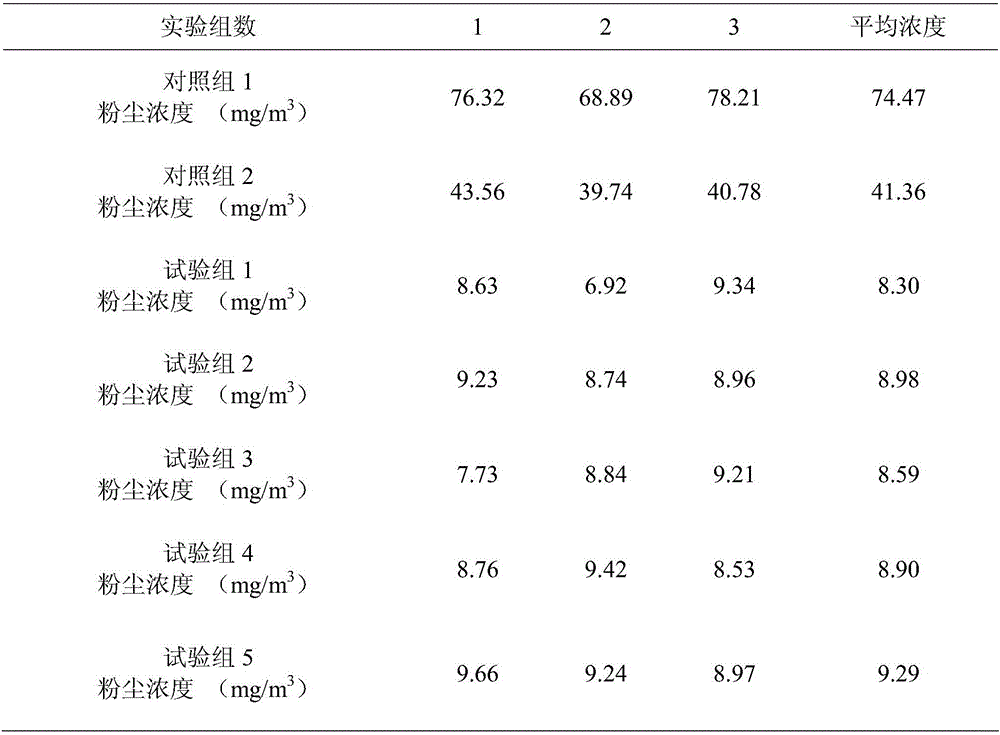

A technology of dust suppressant and parts by weight, applied in the field of dust suppressant and its preparation, can solve the problems of weak binding force between dust and water molecules, no obvious inhibitory effect, and can not satisfy long-term dust suppression, and achieve the dust suppression effect. Significant effect, long dust suppression time, good evaporation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

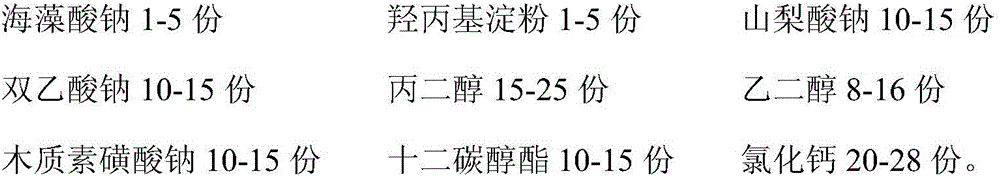

[0039] A dust suppressant, the raw material composition and parts by weight of the active ingredients of the dust suppressant are:

[0040] 5 parts of sodium alginate, 5 parts of hydroxypropyl starch, 15 parts of sodium sorbate

[0041] 15 parts of sodium diacetate 25 parts of propylene glycol 16 parts of ethylene glycol

[0042] 15 parts of sodium lignosulfonate, 15 parts of dodecyl alcohol ester, 28 parts of calcium chloride.

Embodiment 2

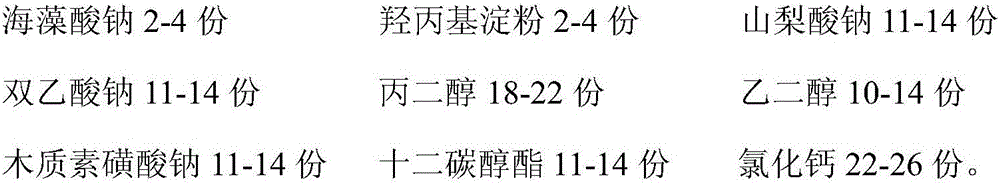

[0044] A dust suppressant, the raw material composition and parts by weight of the active ingredients of the dust suppressant are:

[0045] 4 parts of sodium alginate, 4 parts of hydroxypropyl starch, 14 parts of sodium sorbate

[0046] 14 parts of sodium diacetate 23 parts of propylene glycol 14 parts of ethylene glycol

[0047] 14 parts of sodium lignosulfonate, 14 parts of dodecyl alcohol ester, 26 parts of calcium chloride.

Embodiment 3

[0049] A dust suppressant, the raw material composition and parts by weight of the active ingredients of the dust suppressant are:

[0050] 3 parts of sodium alginate 3 parts of hydroxypropyl starch 12 parts of sodium sorbate

[0051] 12 parts of sodium diacetate 20 parts of propylene glycol 12 parts of ethylene glycol

[0052] 12 parts of sodium lignosulfonate, 12 parts of dodecyl alcohol ester, 24 parts of calcium chloride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com