Production process for boiling chicken feet

A production process and chicken feet technology, which is applied in the field of the production process of boiled chicken feet, can solve the problems of lack of umami, greasy, hard cortex, etc., and achieve the effect of rich nutrition and beautiful color and luster.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. The composition of raw materials is as follows:

[0024] ①Main material

[0025] Chicken feet 145 servings

[0026] ② Raw material formula of marinade:

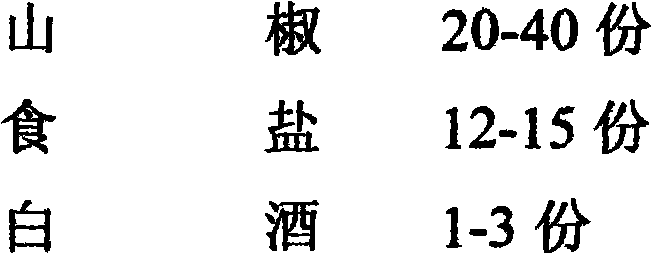

[0027] A recipe:

[0028]

[0029]

[0030] 2. Prepare according to the following process steps and process parameters:

[0031] (1) Cooking soup: put the raw materials of formula A into drinking water and cook for 35 minutes after boiling, then add the raw materials of formula B, stir well, and cool the above pickling solution to room temperature 16°C in an air-conditioned room -18°C;

[0032] (2) Material selection: select chicken feet with good quality, thaw and disinfect them;

[0033] (3) Cooking: Break the chicken feet according to the production requirements, and put them into boiling drinking water for cooking. The cooking time for a single claw is 10 minutes, and the cooking time for broken claws is 7 minutes. The product is required to be cooked before cooking. The degree of control reaches 100...

Embodiment 2

[0037] 1. Raw material composition:

[0038] ①Main material

[0039] 150 chicken feet

[0040] ② Raw material formula of marinade:

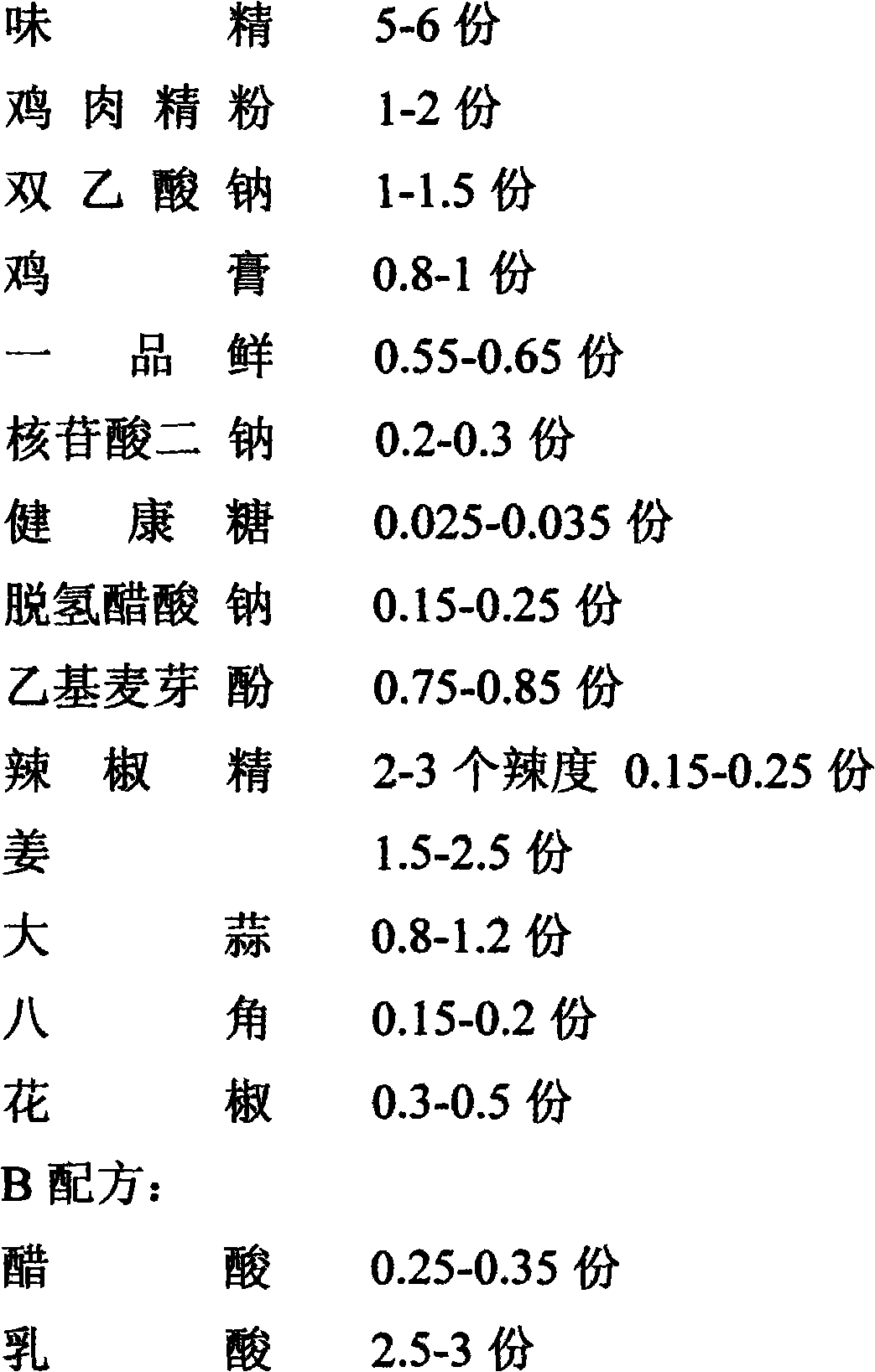

[0041] A recipe:

[0042]

[0043]

[0044] 2. Prepare according to the following process steps and process parameters:

[0045] (1) Cooking soup: put the raw materials of formula A into drinking water and cook for 35 minutes after boiling, then add the raw materials of formula B, stir well, and cool the above pickling solution to room temperature 16°C in an air-conditioned room -18°C;

[0046] (2) Material selection: select chicken feet with good quality, thaw and disinfect them;

[0047] (3) Cooking: Break the chicken feet according to the production requirements, and put them into boiling drinking water for cooking. The cooking time for single claws is 11 minutes, and the cooking time for broken claws is 8 minutes. The products are required to be cooked before cooking. The degree of control reaches 100%, and the above-mentioned chi...

Embodiment 3

[0051] 1. The composition of raw materials is as follows:

[0052] ①Main material

[0053] Chicken feet 160 servings

[0054] ② Raw material formula of marinade:

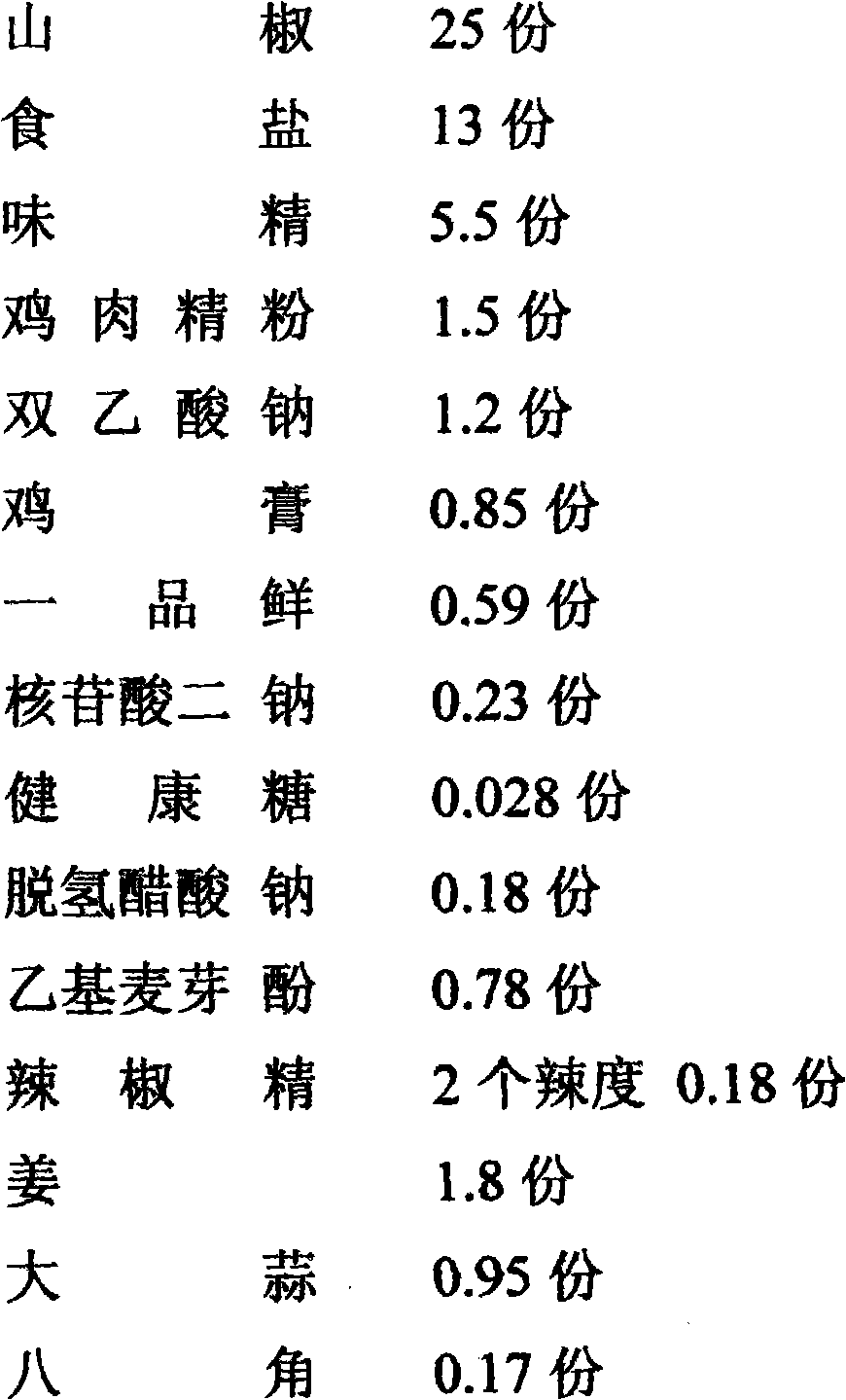

[0055] A recipe:

[0056]

[0057] 2. Prepare according to the following process steps and process parameters:

[0058] (1) Soup: Cook soup: Put the raw materials of formula A into the boiling water and cook for 35 minutes, then put the raw materials of formula B into the pot before starting the pot, continue cooking for 5 minutes, start the pot, stir evenly, add the above pickled liquid Cool in an air-conditioned room to room temperature 16°C-18°C;

[0059] (2) Material selection: select chicken feet with good quality, thaw and disinfect them;

[0060] (3) Cooking: Break the chicken feet according to the production requirements, and put them into boiling drinking water for cooking. The cooking time for single claws is 12 minutes, and the cooking time for broken claws is 8 minutes. It is required that the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com