Preparation method of super wetting titanium dioxide nanorod porous membrane and application of super wetting titanium dioxide nanorod porous membrane to emulsion separation

A titanium dioxide, super-wetting technology, applied in the field of titanium dioxide nanorod porous membrane and its preparation, super-wetting porous membrane and its preparation, can solve the problems of poor stability and limitations, and achieve high-efficiency separation, good application value, and convenient emulsion separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this example, weigh 4g of PVP, 4g of glacial acetic acid, and 20g of ethanol in a 50mL Erlenmeyer flask, and continuously magnetically stir for 12h until completely dissolved to obtain a polymer PVP solution; at room temperature, weigh 12g of tetrabutyl titanate in In the aforementioned polymer PVP solution, the raw material was sealed with a conical bottle mouth, and magnetically stirred continuously at room temperature for 24 hours to form a yellow homogeneous and transparent spinning solution B.

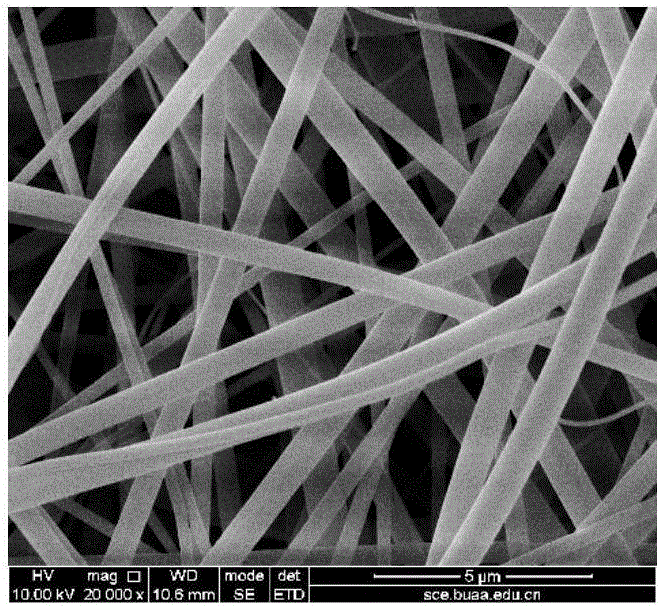

[0034] Fill the spinning solution B into a syringe with a capacity of 10 mL, and advance at a speed of 4 mL / h. Connect the needle of the syringe to the positive pole of the high-voltage DC power supply, use tin foil as the receiving base, fix it on the roller, and connect it to the negative pole of the high-voltage power supply. Spinning parameters were adjusted: the electrospinning voltage was 19kV, the distance between the stainless steel needle and the receiving subst...

Embodiment 2

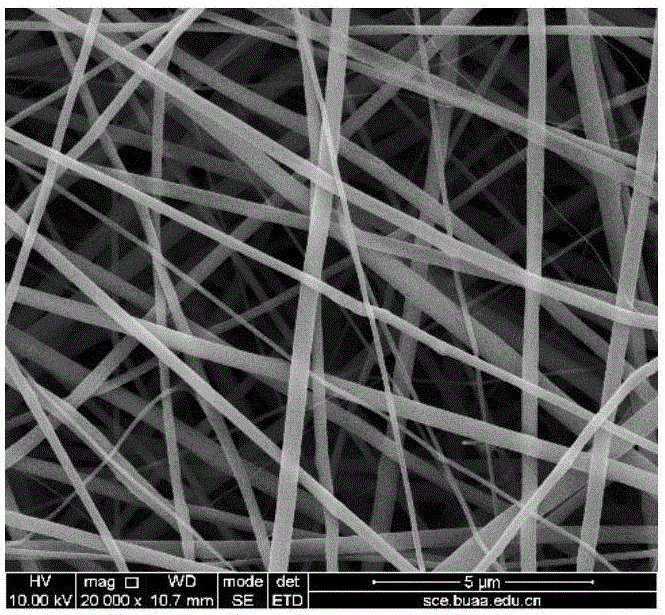

[0040] In this example, weigh 0.5g of PVP, 2.0g of glacial acetic acid, and 7.5g of ethanol in a 50mL Erlenmeyer flask, and continuously magnetically stir for 12h until completely dissolved; at room temperature, weigh 2.0g of tetrabutyl titanate in the aforementioned solution In the process, the raw material was sealed with a conical bottle mouth, and continuously magnetically stirred for 24 hours to form a yellow homogeneous and transparent spinning solution. Fill the spinning solution into a syringe with a capacity of 5 mL, and advance at a speed of 0.8 mL / h. Connect the needle of the syringe to the positive pole of the high-voltage DC power supply, use tin foil as the receiving base, fix it on the roller, and connect it to the negative pole of the high-voltage power supply. Adjust the spinning parameters: the electrospinning voltage is 15kV, the distance between the stainless steel needle and the receiving drum is adjusted to 18cm, and the rotating speed of the drum is 800r...

Embodiment 3

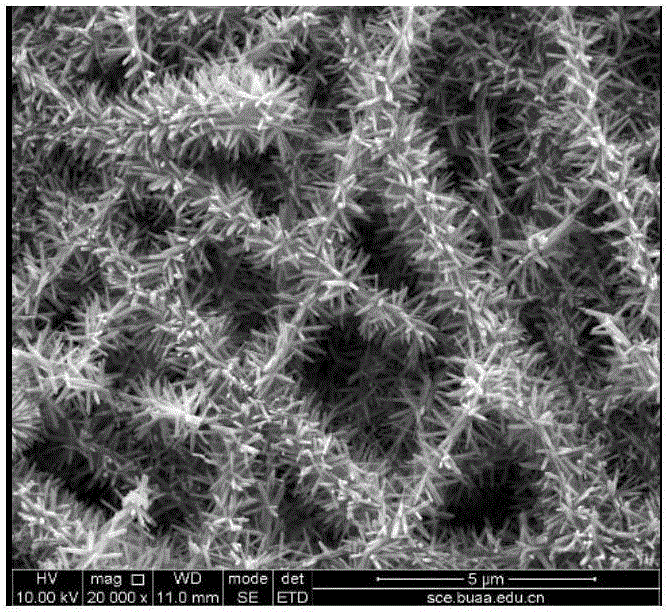

[0045] In this example, weigh 4.0g of PVP, 4.0g of glacial acetic acid, and 20g of ethanol in a 50mL Erlenmeyer flask, and continuously magnetically stir for 12h until completely dissolved; under ice bath conditions, weigh 12.0g of titanium isopropoxide in the aforementioned solution , Raw materials with sealed Erlenmeyer mouth, continuous magnetic stirring for 24h, forming a yellow homogeneous transparent spinning solution. Fill the spinning solution into a syringe with a capacity of 5 mL, and advance at a speed of 2 mL / h. Connect the needle of the syringe to the positive pole of the high-voltage DC power supply, use tin foil as the receiving base, fix it on the roller, and connect it to the negative pole of the high-voltage power supply. Adjust the spinning parameters: the electrospinning voltage is 20kV, the distance between the stainless steel needle and the receiver is adjusted to 25cm, and the drum speed is 1000r / min. Obtained PVP / TiO 2 The fiber diameter is relatively...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com