Method for preparing high-strength graphite oxide aerogel

A graphene aerogel, high-strength technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve problems such as restricting application and low strength, and achieve controllable shape, large specific surface area, and good mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

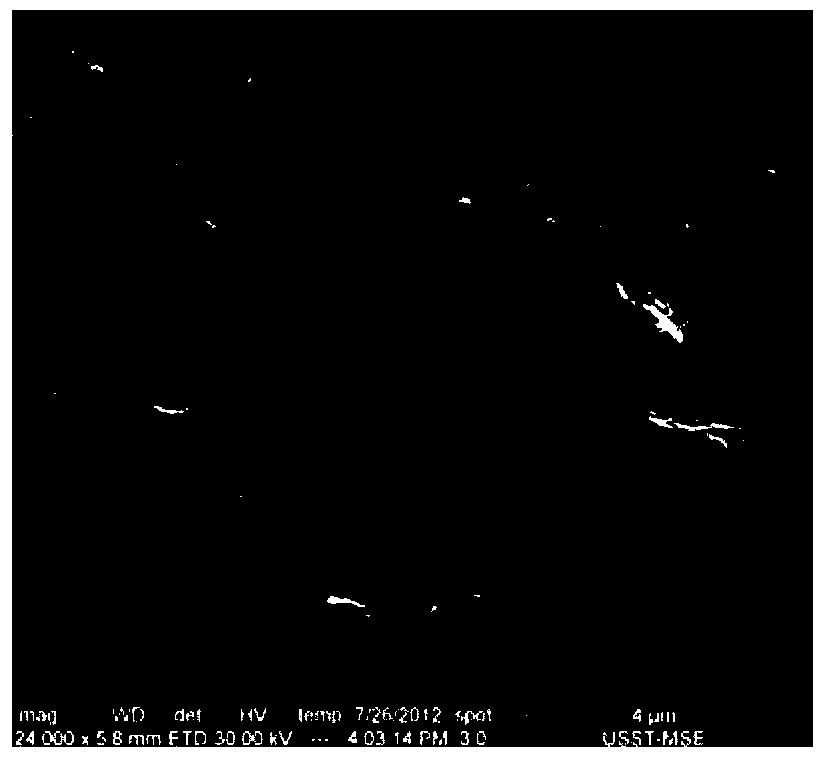

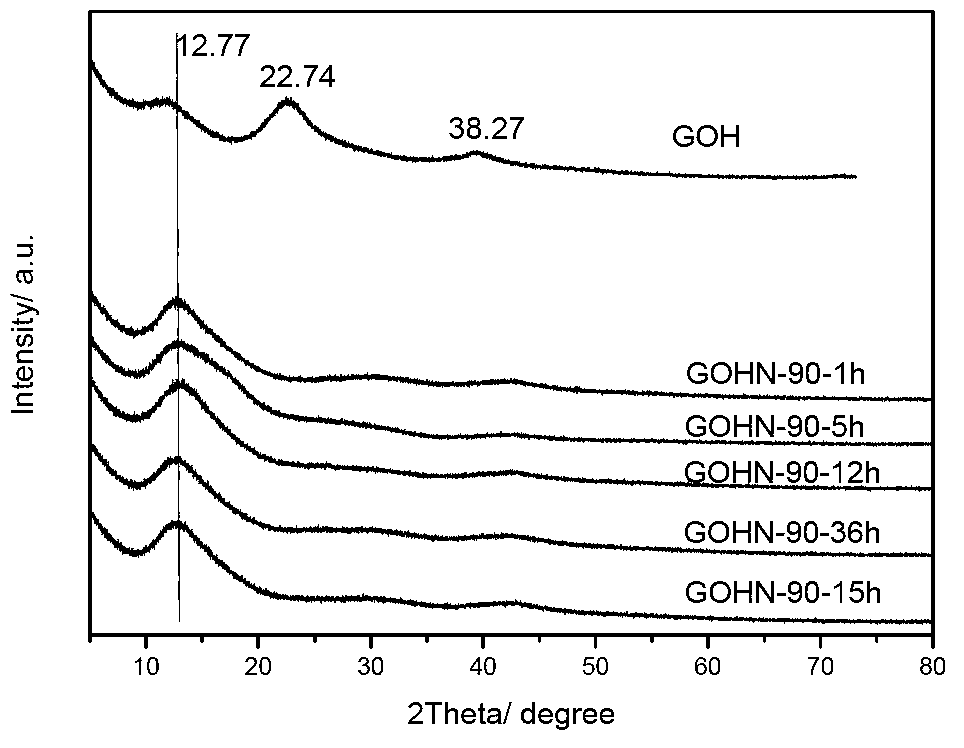

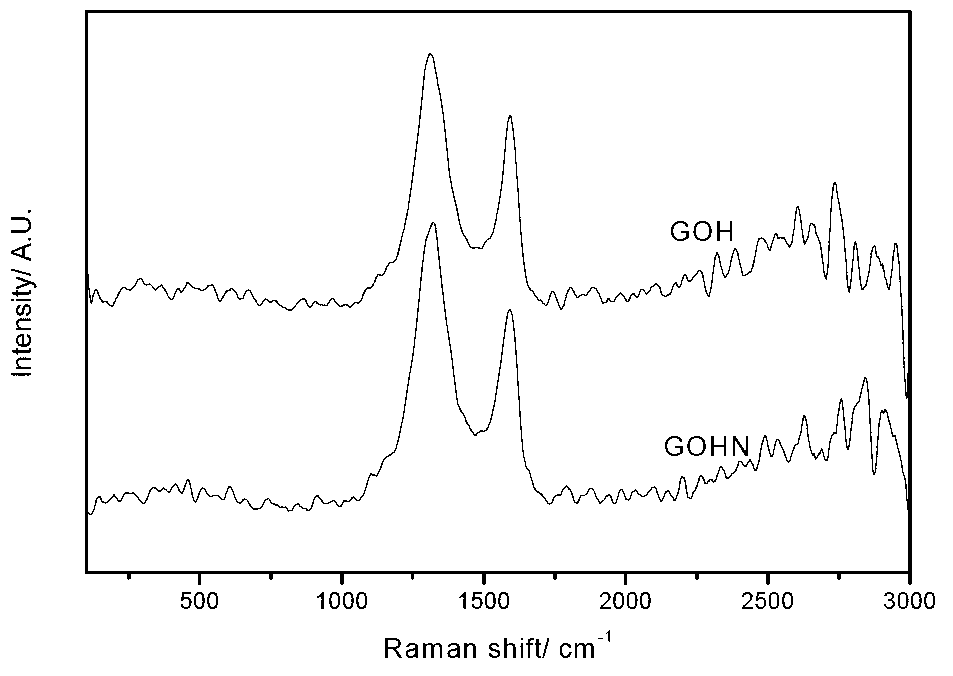

[0017] Graphene oxide was formulated into an aqueous solution with a concentration of 2 mg / ml, and ultrasonically oscillated for 2 hours to obtain a well-dispersed graphene oxide aqueous solution. Add 50ml of graphene oxide aqueous solution into a hydrothermal kettle, and treat at 180°C for 20h to prepare graphene oxide hydrogel. Its SEM picture is as follows figure 1 shown. The prepared graphene oxide hydrogel was put into ammonia water, soaked at 90° C. for 1 hour, and freeze-dried to obtain graphene oxide airgel with high mechanical strength.

Embodiment 2

[0019] Graphene oxide was formulated into an aqueous solution with a concentration of 1 mg / ml, and ultrasonically oscillated for 1 hour to obtain a well-dispersed graphene oxide aqueous solution. Add 10 ml of graphene oxide aqueous solution into a hydrothermal kettle, and treat at 150°C for 5 hours to prepare graphene oxide hydrogel. The prepared graphene oxide hydrogel was put into ammonia water, soaked at 60° C. for 5 hours, and freeze-dried to obtain graphene oxide airgel with high mechanical strength.

Embodiment 3

[0021] Graphene oxide was formulated into an aqueous solution with a concentration of 5 mg / ml, and ultrasonically oscillated for 3 hours to obtain a well-dispersed graphene oxide aqueous solution. Add 200ml of graphene oxide aqueous solution into a hydrothermal kettle and treat at 90°C for 20h to prepare graphene oxide hydrogel. The prepared graphene oxide hydrogel was put into ammonia water, soaked at 0°C for 36 hours, and freeze-dried to obtain graphene oxide airgel with high mechanical strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com