Preparation methods of ceramic slurry for air pressure extrusion type three-dimensional printing and biological ceramic bracket

A technology of three-dimensional printing and ceramic slurry, which is applied in the direction of ceramic molding machines, clay preparation devices, chemical instruments and methods, etc. low shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Step 1: Preparation of high solid content slurry

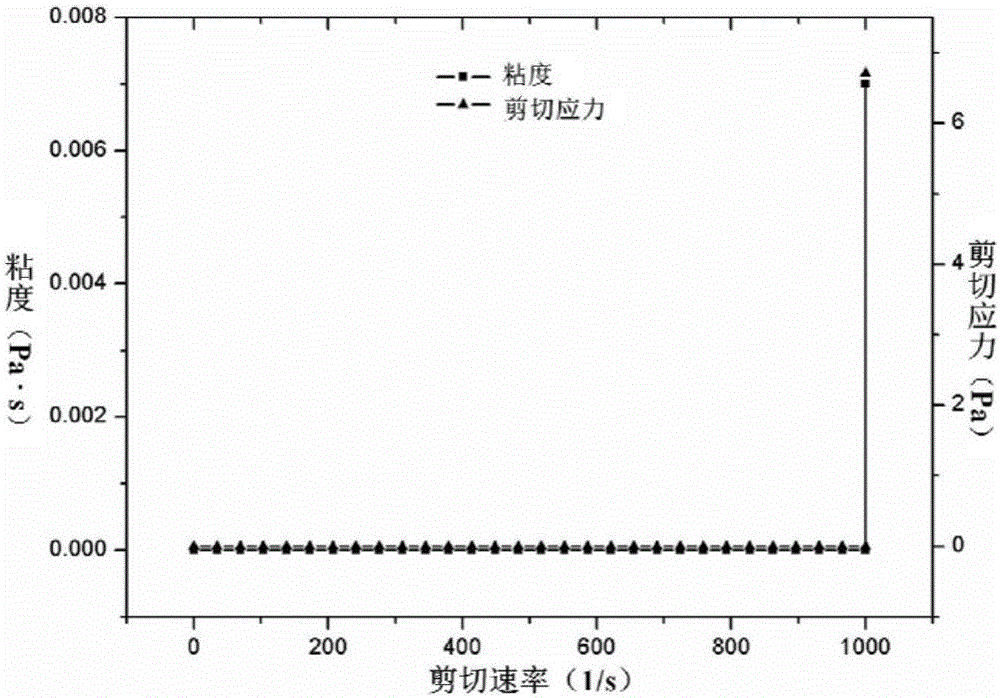

[0040] (1) The micronano-scale spherical β-tricalcium phosphate (β-TCP) powder synthesized by the soluble calcium salt and phosphate reaction process is used as the raw material, and the mixed solution of deionized water and ammonium polyacrylate is used as the solvent. Planetary ball mill ball milling 8h (frequency 30Hz), preparation of slurry with a solid phase content of 45vol%, its rheological properties and viscosity see figure 1 ;

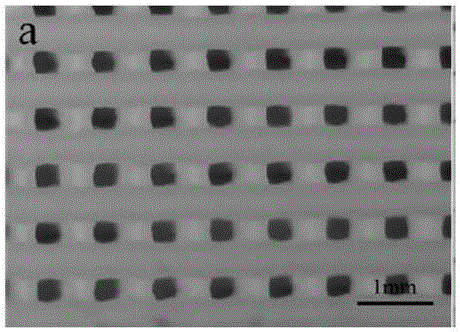

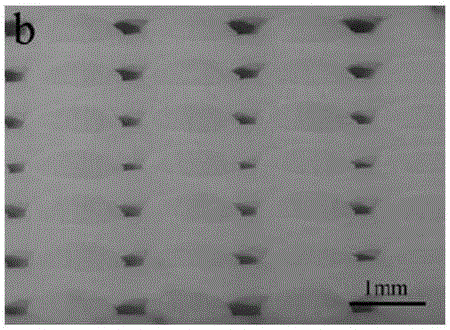

[0041] (2) Add methyl cellulose with a high degree of polymerization into the slurry as a rheological additive, the amount added is 1 wt% of the β-TCP powder, and use a planetary ball mill for high-speed ball milling for 2 hours, and then move the slurry into a barrel. By means of ultrasonic vibration (frequency 100Hz, time 30min, temperature 30°C) and low temperature defoaming (time 12h, temperature 4°C), a bioactive ceramic slurry that can be used for 3D printing is prepared, and th...

Embodiment 2

[0052] Step 1: Preparation of high solid content slurry

[0053] (1) The micro-nano-scale spherical hydroxyapatite (HA) powder synthesized by the reaction process of soluble calcium salt and phosphate was used as the raw material, and the mixture of deionized water and sodium polyacrylate was used as the solvent, and the ball was milled for 8 hours using a planetary ball mill. (Frequency 30Hz), preparing a slurry with a solid phase content of 50vol%;

[0054] (2) Add low-melting point agarose to the slurry as a rheological additive in an amount of 2.5 wt% of the HA powder, use a planetary ball mill for high-speed ball milling and mix for 1 hour, and then move the slurry into a barrel. By means of ultrasonic oscillation (frequency 100Hz, time 30min, temperature 30°C) and low temperature standing (time 12h, temperature 4°C), a bioactive ceramic slurry that can be used for 3D printing is prepared, and the viscosity of the slurry is lower than 100Pa ·S, the solidification time in...

Embodiment 3

[0063] Step 1: Preparation of high solid content slurry

[0064] (1) Using nano-scale bioactive glass (BG) powder synthesized by sol-gel method as raw material, using a mixture of deionized water and stearic acid as solvent, using a planetary ball mill for 3h (frequency 30Hz), the preparation of solid A slurry with a phase content of 40vol%;

[0065] (2) Add xanthan gum with a high degree of polymerization into the slurry as a rheological additive, the addition amount is 2wt% of the powder, use a planetary ball mill for high-speed ball milling and mix for 1 hour, and then move the slurry into a barrel. By means of ultrasonic vibration (frequency 100Hz, time 30min, temperature 30°C) and low temperature standing (time 12h, temperature 2°C), the bioactive ceramic slurry for 3D printing was prepared; the viscosity of the slurry was lower than 100Pa· S, the solidification time in air is less than 1 minute.

[0066] Step 2: Preparation of three-dimensional controllable microstruct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com