Method for producing Nano carbon tubes continuously and equipment

A carbon nanotube and catalyst technology, which is applied in the field of continuous production of carbon nanotubes, can solve the problems of serious overlap and adhesion between particles, clogging reactor production, and destroying the fluidized state, so as to ensure continuous operation and reduce back-mixing. degree, good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

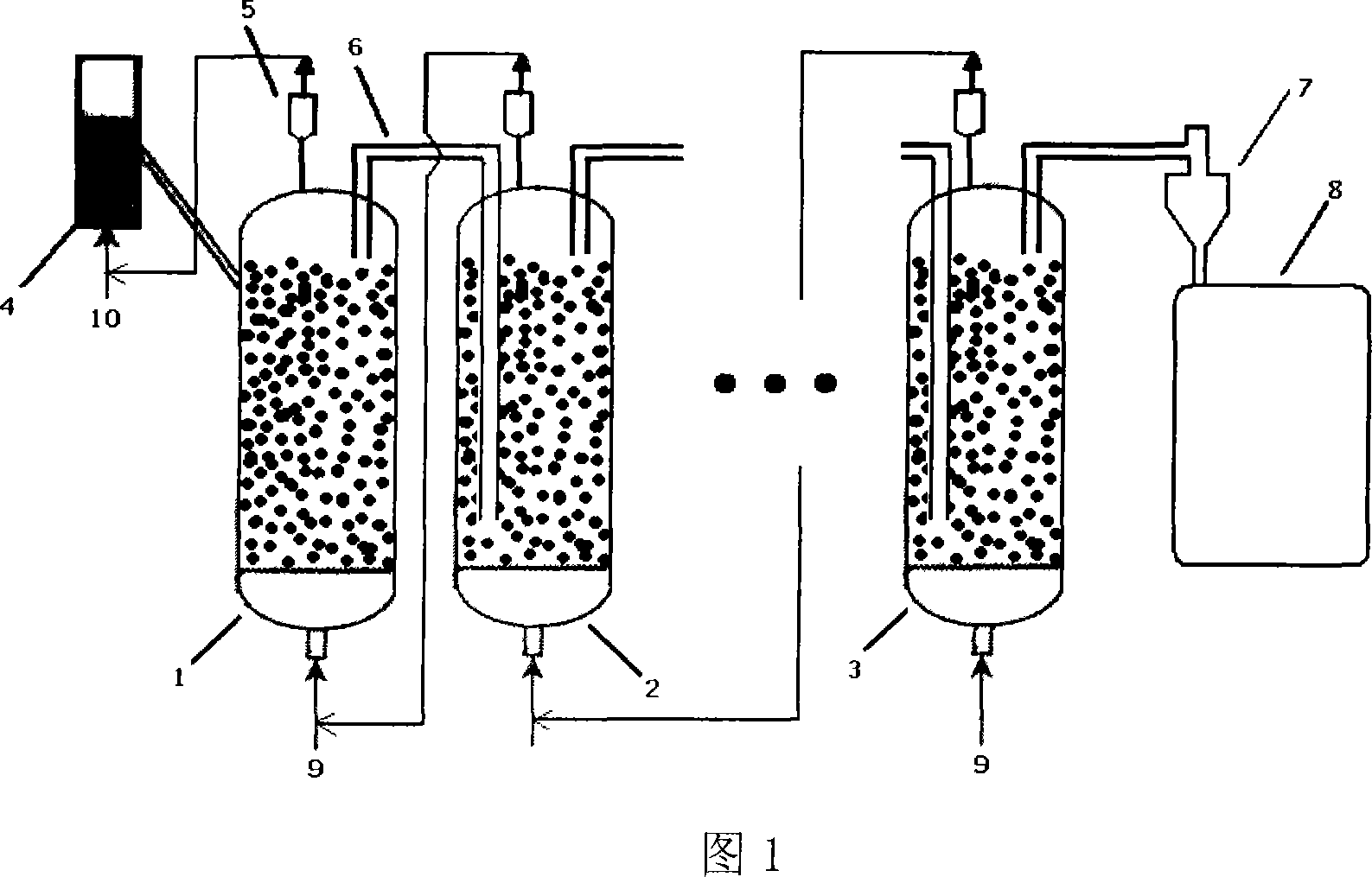

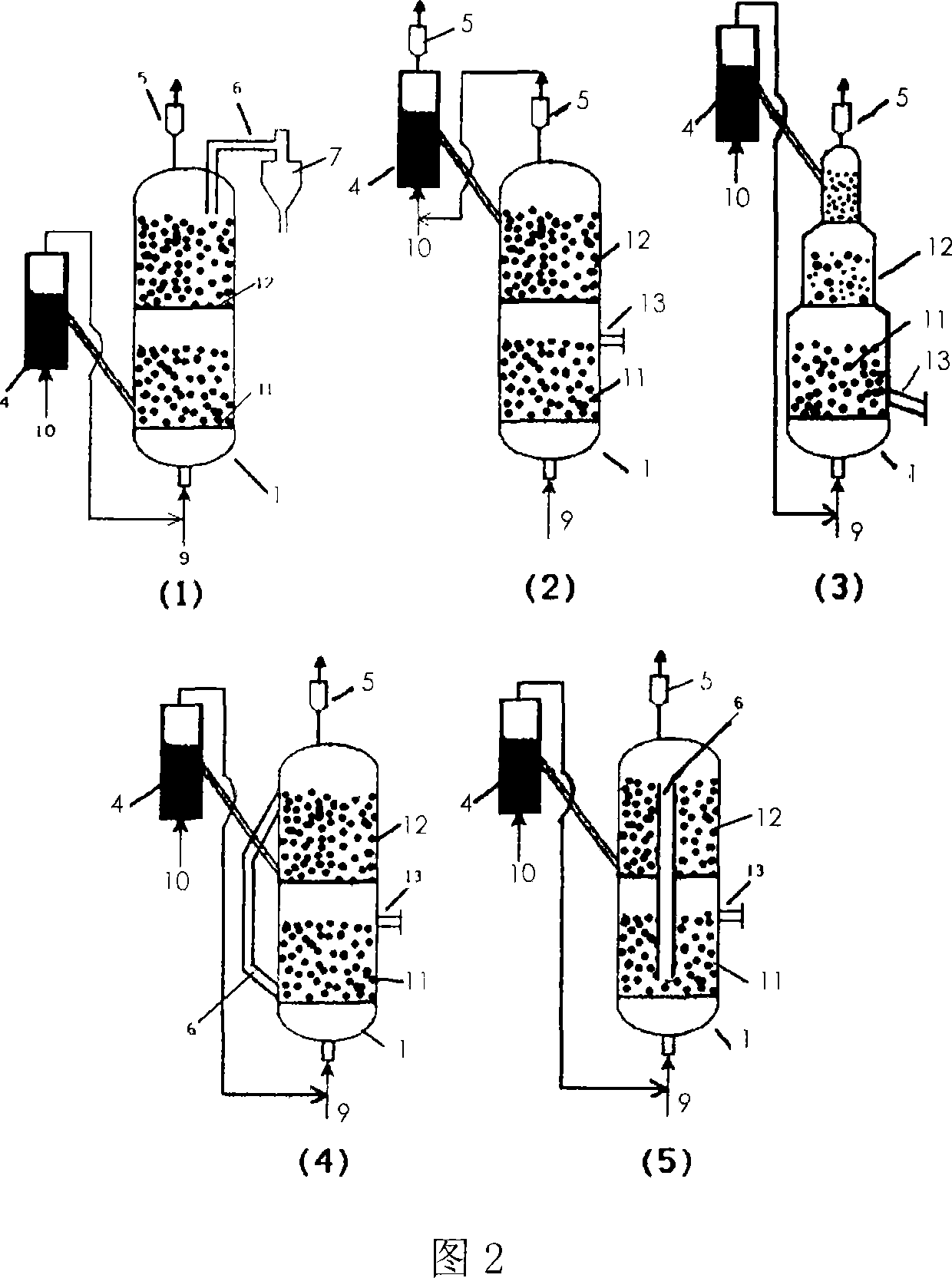

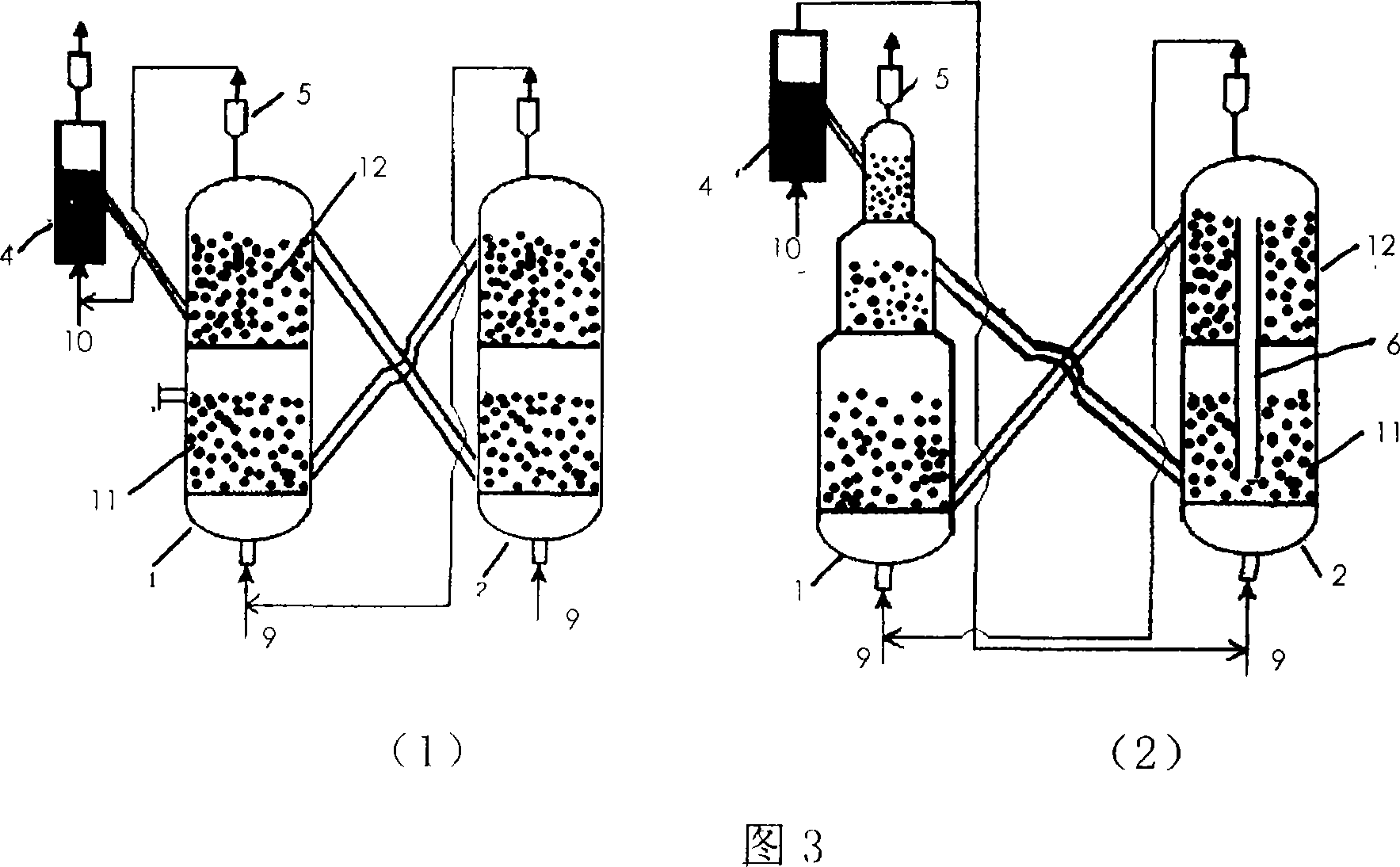

[0031] The invention provides a method and device for continuous production of carbon nanotubes. The present invention adopts a device with multi-stage reactors connected in series, and by separately controlling the distribution and fluidization state of catalysts and carbon nanomaterials in the reactors at each stage, and operating in different regions, the normal fluidization of materials with a relatively large density span can be realized, ensuring The continuous operation is realized, and the high-efficiency conversion of raw materials and the high production capacity of the device are realized at the same time. The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0032] Figure 1 is a schematic diagram of a multi-stage serial fluidized bed reactor for the production of carbon nanotubes. In the figure, the first-stage main reactor 1, the second-stage main reactor 2, ... to the last-stage main reactor 3, are...

Embodiment 1

[0037] A single-stage reactor is used for the reaction, with an inner diameter of 500mm and a height of 2.5m. 1 kg of MWNT catalyst was loaded at one time, the operating gas velocity was 0.05 m / s, and the weight was 13 kg after 5 hours of reaction. It was found that the fluidization state of the solid material was poor and channeling occurred, resulting in a gas conversion rate of only 30%.

[0038] Three examples are given below to illustrate the application of multistage reactors.

[0039] (1) Adopt the device shown in Figure 1, the inner diameter of the second and second main reactors is respectively 200, 500mm, high 2.5m, one-time loading 1kg MWNT catalyst in the first-order main reactor, operating gas velocity 0.3m / s, the operating gas velocity of the second-stage main reactor is 0.05m / s, and no material is loaded. After reacting for 30 minutes, the volume expansion of the solid material in the first-stage main reactor was 250 times, the weight was 5 kg, the average yie...

Embodiment 2

[0043] Using the device shown in Figure 1, an alternating coil (magnetic field strength 1000A / m) is used to generate an alternating magnetic field at the outer wall of the main reactor of the first stage and the last stage. Since the catalyst contains iron particles, it is in the alternating magnetic field. It is constantly beating, which can obviously improve the fluidization quality.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com