Large-area ultra-thin carbon nanotube film and its preparation process

A carbon nanotube film and carbon nanotube technology, applied in the field of carbon nanomaterial synthesis and application, can solve the problems of difficulty in forming a continuous film, performance degradation, etc., and achieve the effects of less environmental pollution and simple process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

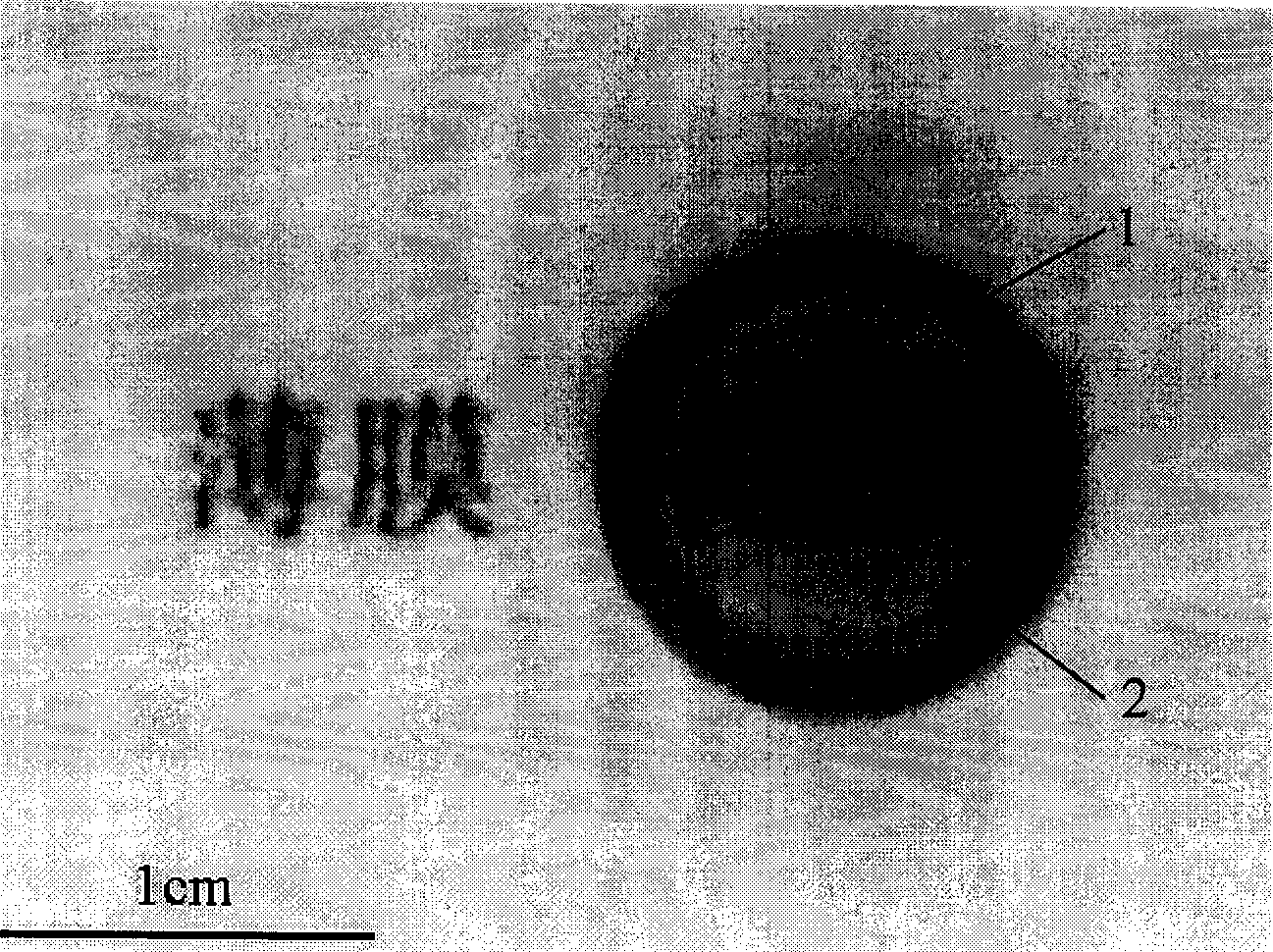

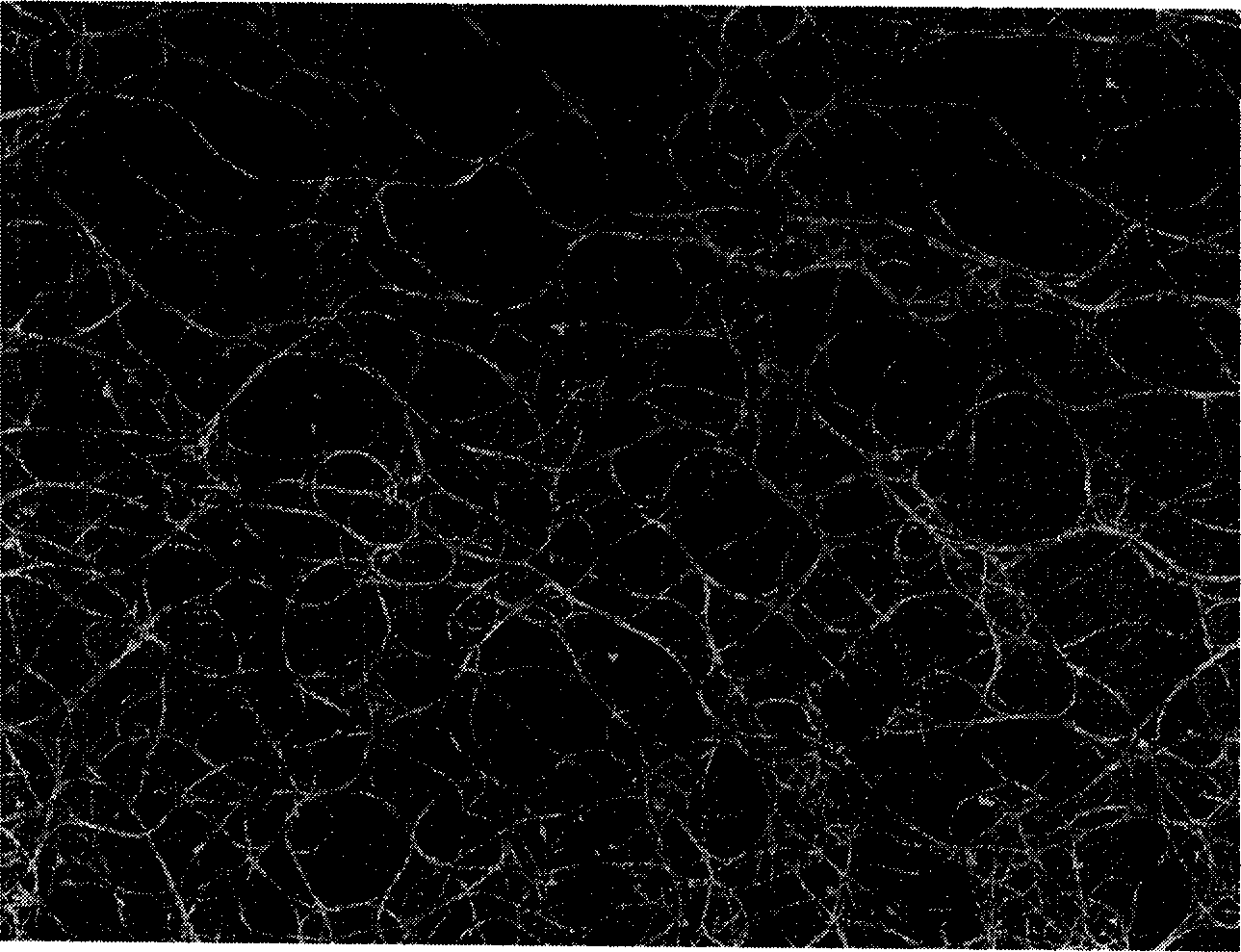

[0033] Example 1: Taking the double-walled carbon nanotube film as an example, an alcohol solution is used as a spreading agent and collected with a silicon wafer. The specific steps are:

[0034] 1) Weigh 0.25 g of a mixture of ferrocene and sulfur with a molar ratio of 10:1 and dissolve it in 10 ml of xylene solution to prepare a reaction solution.

[0035] 2) Raise the temperature of the horizontal reaction chamber to 1150°C, feed 2000mL / min of argon and 400mL / min of hydrogen, and send the reaction solution into the reaction chamber at a rate of 0.1mL / min. The black carbon nanotube film produced in the reaction zone drifts out with the airflow and is deposited at the back end of the reaction chamber.

[0036] 3) After the reaction is over, stop feeding the reaction solution, stop feeding hydrogen and reduce the flow rate of argon, and cool the reaction chamber to room temperature.

[0037] 4) Take out the black double-walled carbon nanotube macroscopic body from the reacti...

example 2

[0046] Example 2: Taking the single-walled carbon nanotube film as an example, using acetone solution as the spreading agent and collecting it with a quartz ring, the specific steps are:

[0047] 1) Weigh 0.05 g of a mixture of ferrocene and sulfur with a molar ratio of 100:5 and dissolve it in 10 ml of n-hexane solution to prepare a reaction solution.

[0048] 2) Raise the temperature of the horizontal reaction chamber to 1200°C, feed 3000mL / min of argon and 1000mL / min of hydrogen, and send the reaction solution into the reaction chamber at a rate of 0.05mL / min. The black carbon nanotube film produced in the reaction zone drifts out with the airflow and is deposited at the back end of the reaction chamber.

[0049] 3) After the reaction is over, stop feeding the reaction solution, stop feeding hydrogen and reduce the flow rate of argon, and cool the reaction chamber to room temperature.

[0050] 4) Take out the black single-walled carbon nanotube macroscopic body from the re...

example 3

[0057] Example 3: Taking the multi-walled carbon nanotube film as an example, using alcohol as a spreading agent and collecting it with a metal substrate, the specific steps are:

[0058] 1) Weigh 0.3 g of a mixture of ferrocene and sulfur with a molar ratio of 10:25 and dissolve it in 10 ml of benzene solution to prepare a reaction solution.

[0059] 2) Raise the temperature of the horizontal reaction chamber to 900°C, feed 500mL / min of argon and 200mL / min of hydrogen, and send the reaction solution into the reaction chamber at a rate of 0.3mL / min. The black carbon nanotube film produced in the reaction zone drifts out with the airflow and is deposited at the back end of the reaction chamber.

[0060] 3) After the reaction is over, stop feeding the reaction solution, stop feeding hydrogen and reduce the flow rate of argon, and cool the reaction chamber to room temperature.

[0061] 4) Taking out the multi-walled carbon nanotube macroscopic body from the reaction chamber.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com