Permanent magnet embedded type rotating electric machine

A technology of rotating electrical machines and permanent magnets, which is applied in the direction of magnetic circuit rotating parts, magnetic circuits, electromechanical devices, etc., which can solve the problems of inability to effectively cool permanent magnets and achieve effective cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

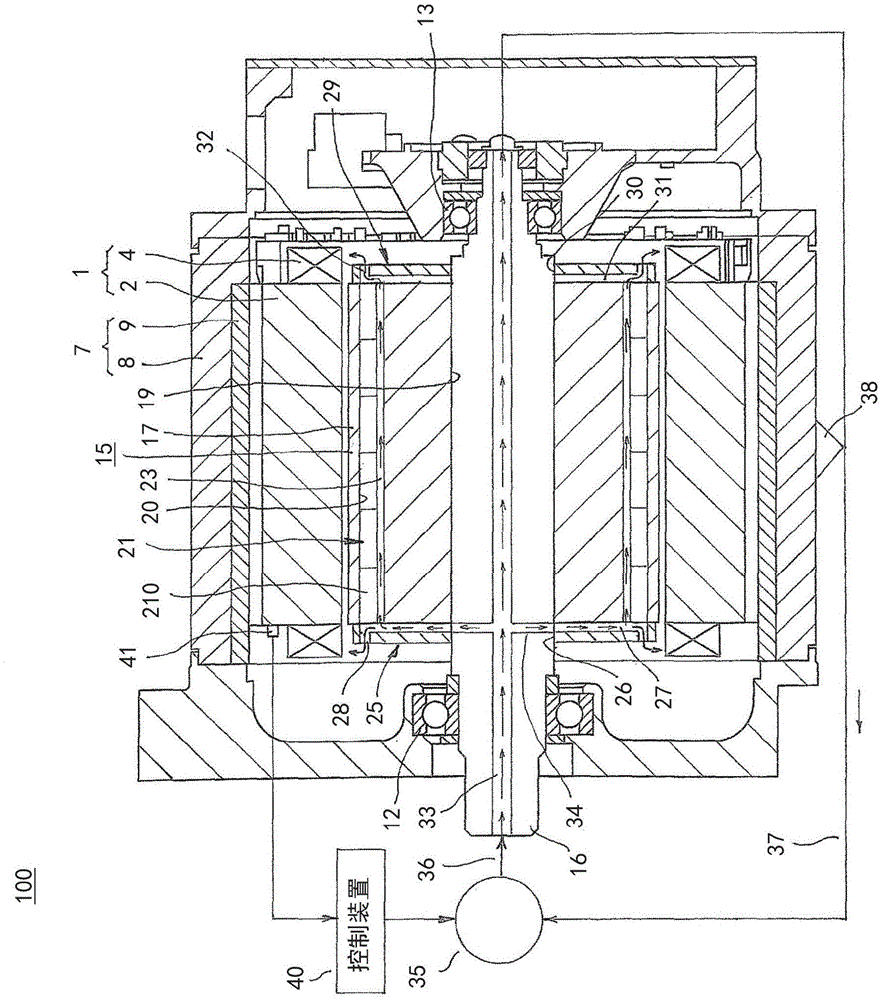

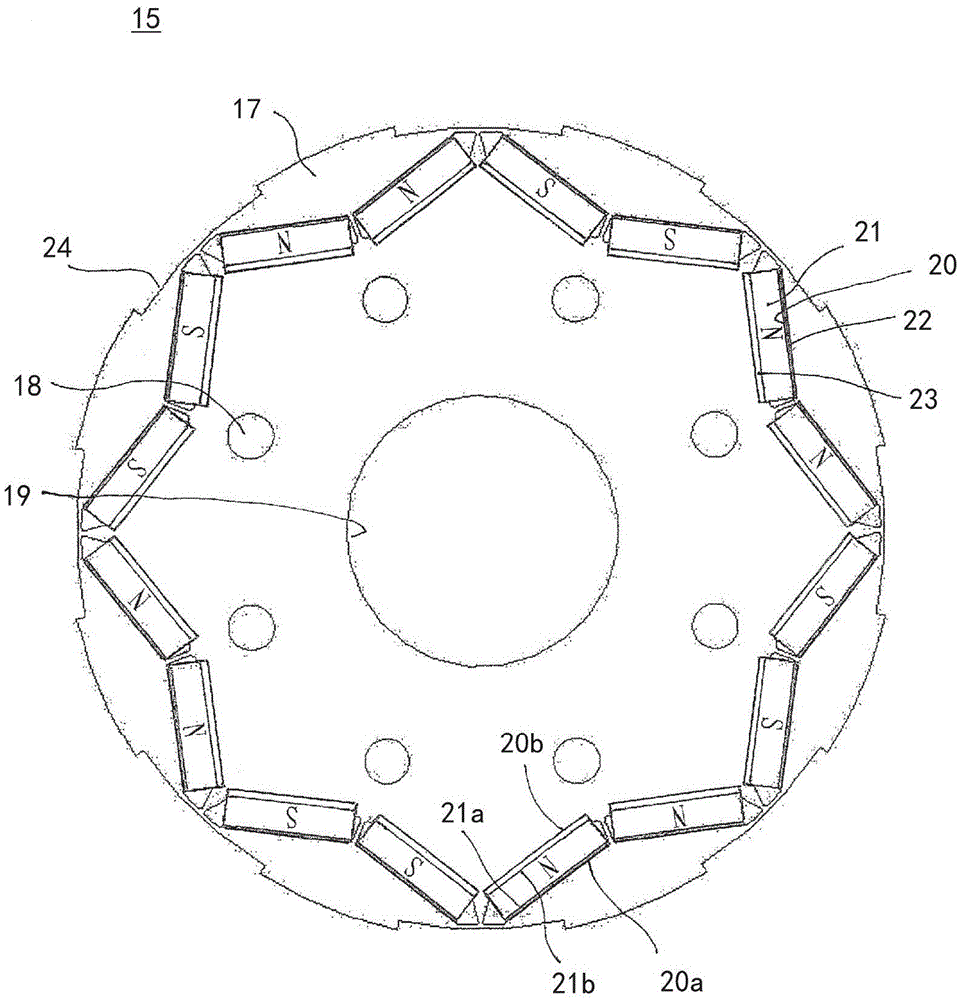

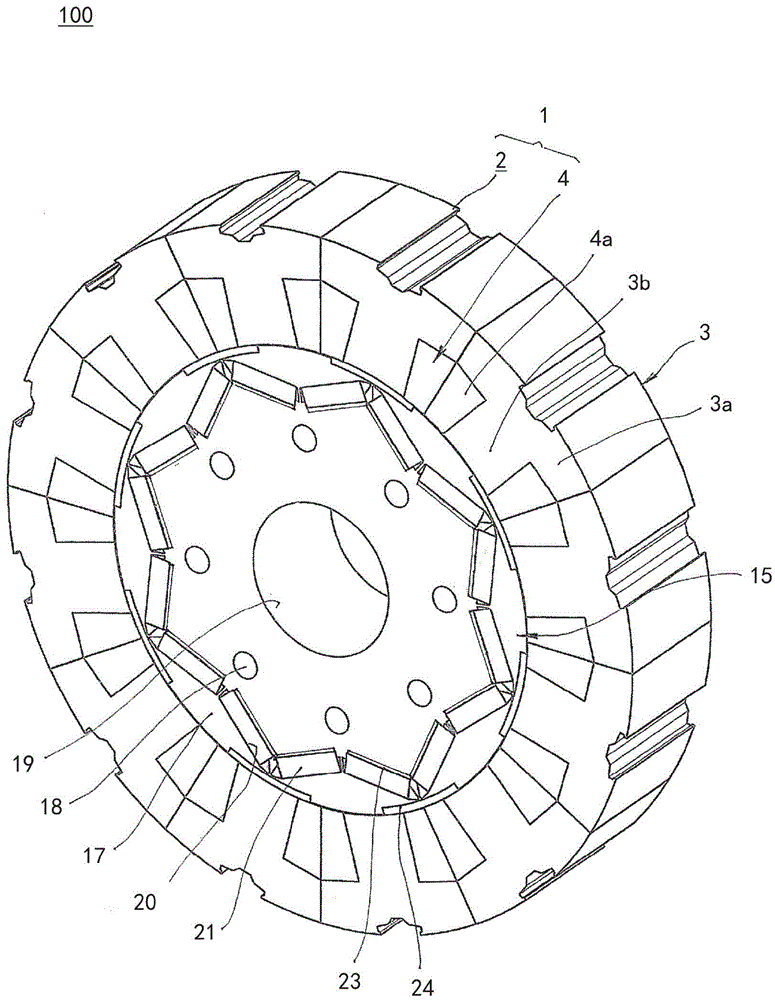

[0028] figure 1 is a sectional view showing the permanent magnet embedded rotating electrical machine according to Embodiment 1 of the present invention, figure 2 It is an end view showing the rotor core in the permanent magnet embedded rotating electrical machine according to Embodiment 1 of the present invention, image 3 It is a perspective view illustrating a state in which a rotor core is assembled in a stator of a permanent magnet embedded rotating electrical machine according to Embodiment 1 of the present invention, Figure 4 It is a flowchart showing a drive control method of the external oil delivery equipment in the permanent magnet embedded rotating electrical machine according to Embodiment 1 of the present invention. also, figure 1 The middle arrows indicate the flow direction of cooling oil.

[0029] Figure 1 to Figure 3 Among them, the permanent magnet embedded type rotating electrical machine 100 includes: an annular stator 1; a cylindrical frame 7 that ...

Embodiment approach 2

[0064] Figure 5 It is a sectional view showing a permanent magnet embedded rotating electrical machine according to Embodiment 2 of the present invention.

[0065] Figure 5 Here, the in-shaft flow path 33A is formed to extend from one end in the axial direction at the axial center of the shaft 16A to a position radially below the introduction flow path 27 formed in the first end plate 25 . Furthermore, the branch flow path 34 is formed on the shaft 16A so as to communicate with the other axial end of the in-shaft flow path 33A and the introduction flow path 27 .

[0066] In addition, other configurations are configured in the same manner as in the first embodiment described above.

[0067] In the permanent magnet embedded rotating electrical machine 101 configured in this way, the in-shaft flow path 33A is formed only on the front side of the shaft 16A, so that the cost of the shaft 16A can be reduced.

Embodiment approach 3

[0069] Image 6 It is a cross-sectional view showing a permanent magnet embedded rotating electrical machine according to Embodiment 3 of the present invention.

[0070] Image 6 Among them, the cross-sectional areas of the first discharge passage 28 , the cooling flow passage 23 , and the second discharge passage 32 become larger in the order of the first discharge passage 28 , the cooling flow passage 23 , and the second discharge passage 32 .

[0071] In addition, other configurations are configured in the same manner as in the first embodiment described above.

[0072] In the permanent magnet embedded rotating electrical machine 102 thus constituted, the flow passage sectional area of the first discharge passage 28 is smaller than the passage cross-sectional area of the cooling passage 23, and therefore, the cooling oil flowing through the introduction passage 27 is discharged from the first discharge passage 28. The outflow amount of the discharge passage 28 is rest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com