High slot-fill factor high-performance permanent magnet motor with open slots and straight teeth

A technology of permanent magnet motor and slot full rate, which is applied in the direction of synchronous motor with stationary armature and rotating magnet, magnetic circuit stationary parts, magnetic circuit rotating parts, etc. It can solve the problems affecting the application of high precision servo drive, Sacrifice power, inconvenient assembly and other issues to achieve the effect of saving rotor space, good heat dissipation performance, and reduced inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

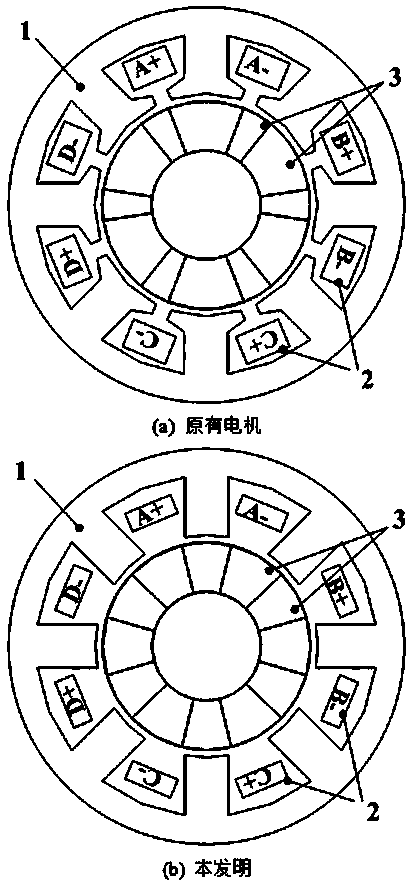

[0030] Taking the 4-phase, 8-slot, 6-pole permanent magnet as an example, its structure diagram is shown in figure 1 , the present invention is made up of stator core 1, stator winding 2, rotor permanent magnet 3. Eight armature straight teeth are evenly distributed on the stator core 1, and a set of concentrated windings is wound on each armature tooth and forms a phase by itself. Pole arc coefficient of stator core 1 k s =0.5. The stator winding is wound on the mould, fixed with glue, and then transplanted into the stator slot. The filling rate of the winding slot is about 68%, which is 18% higher than before. The wound windings are potted with epoxy resin glue, image 3 This is the picture of the motor after potting.

[0031] There is an air gap between the stator 1 and the rotor permanent magnet 3, here the value is 1mm.

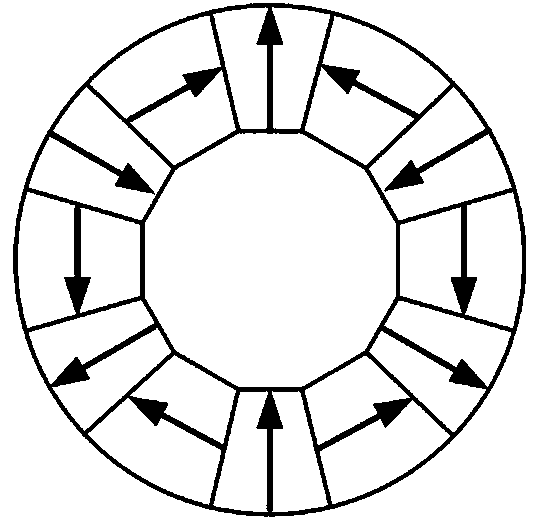

[0032] The number of poles of the rotor permanent magnet 3 is 6, and the permanent magnet pole arc coefficient of the radial magnetization directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com