Moving-magnetic type linear motor

A linear motor and moving magnet technology, applied in the direction of magnetic circuit shape/style/structure, electromechanical devices, electrical components, etc., can solve the difficulty of increasing yoke processing, installation and maintenance, lack of simple and effective methods, and is not conducive to Solve problems such as armature heat dissipation, achieve easy processing, improve the utilization rate of permanent magnets, and improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with accompanying drawing and example.

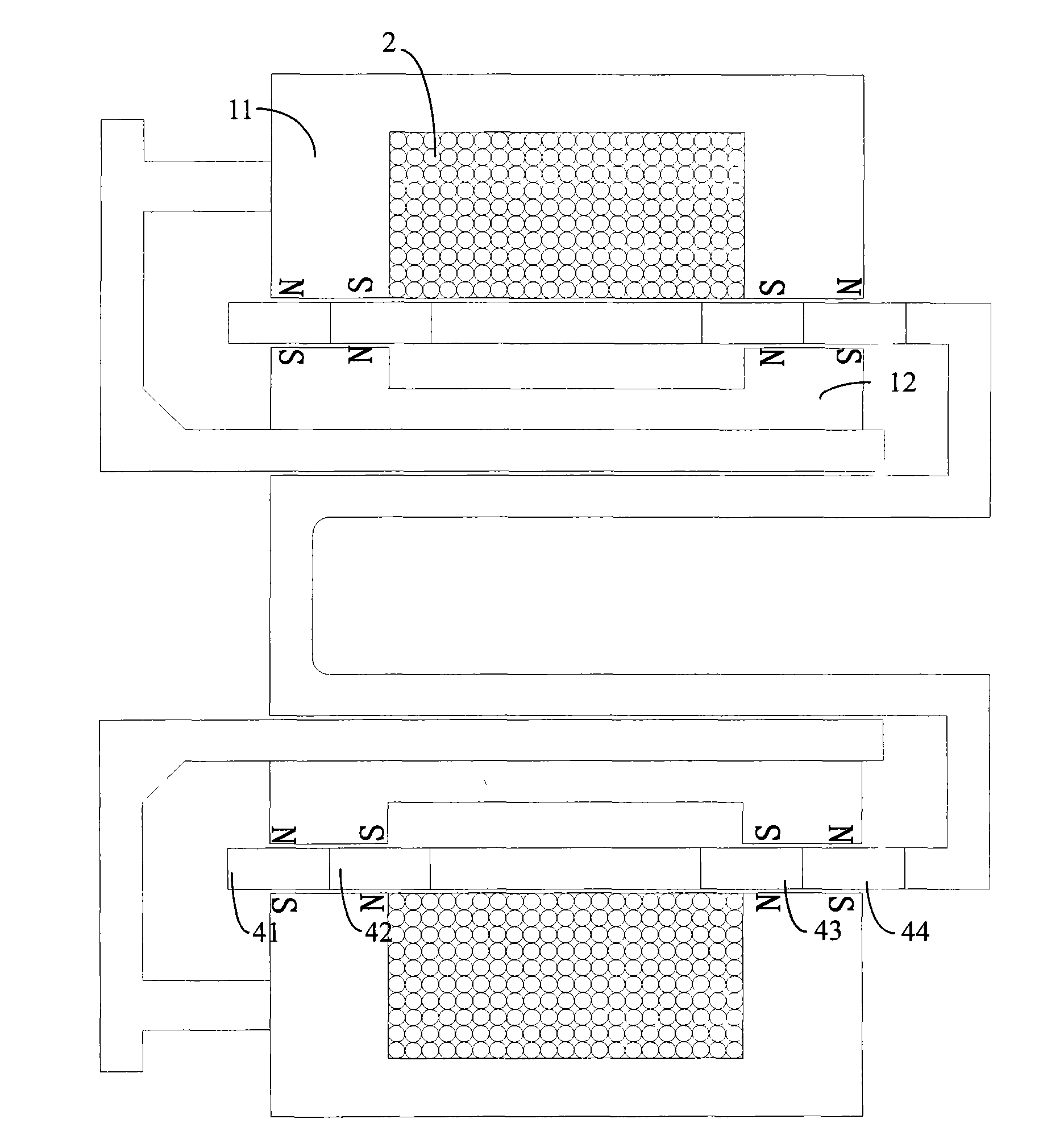

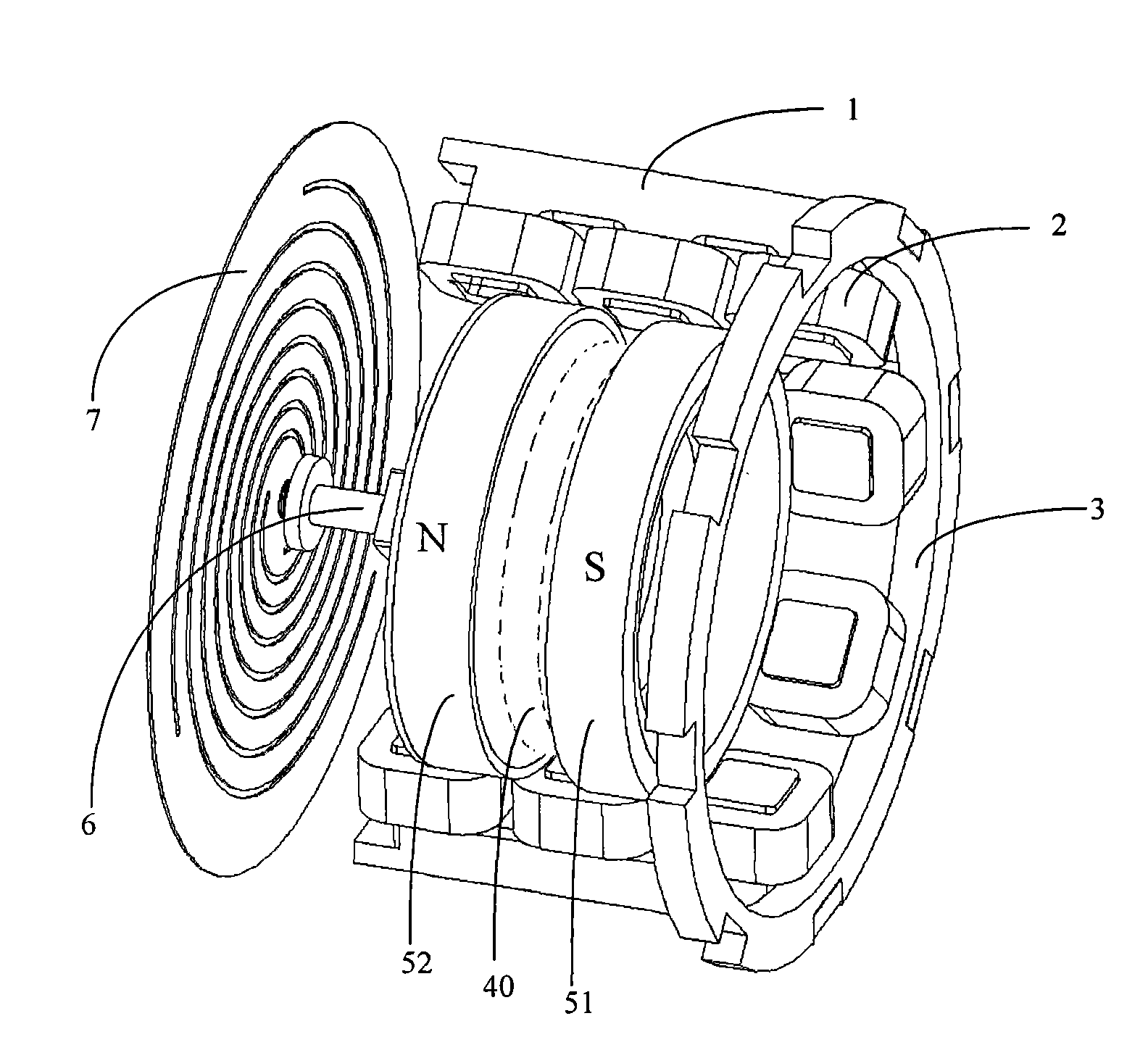

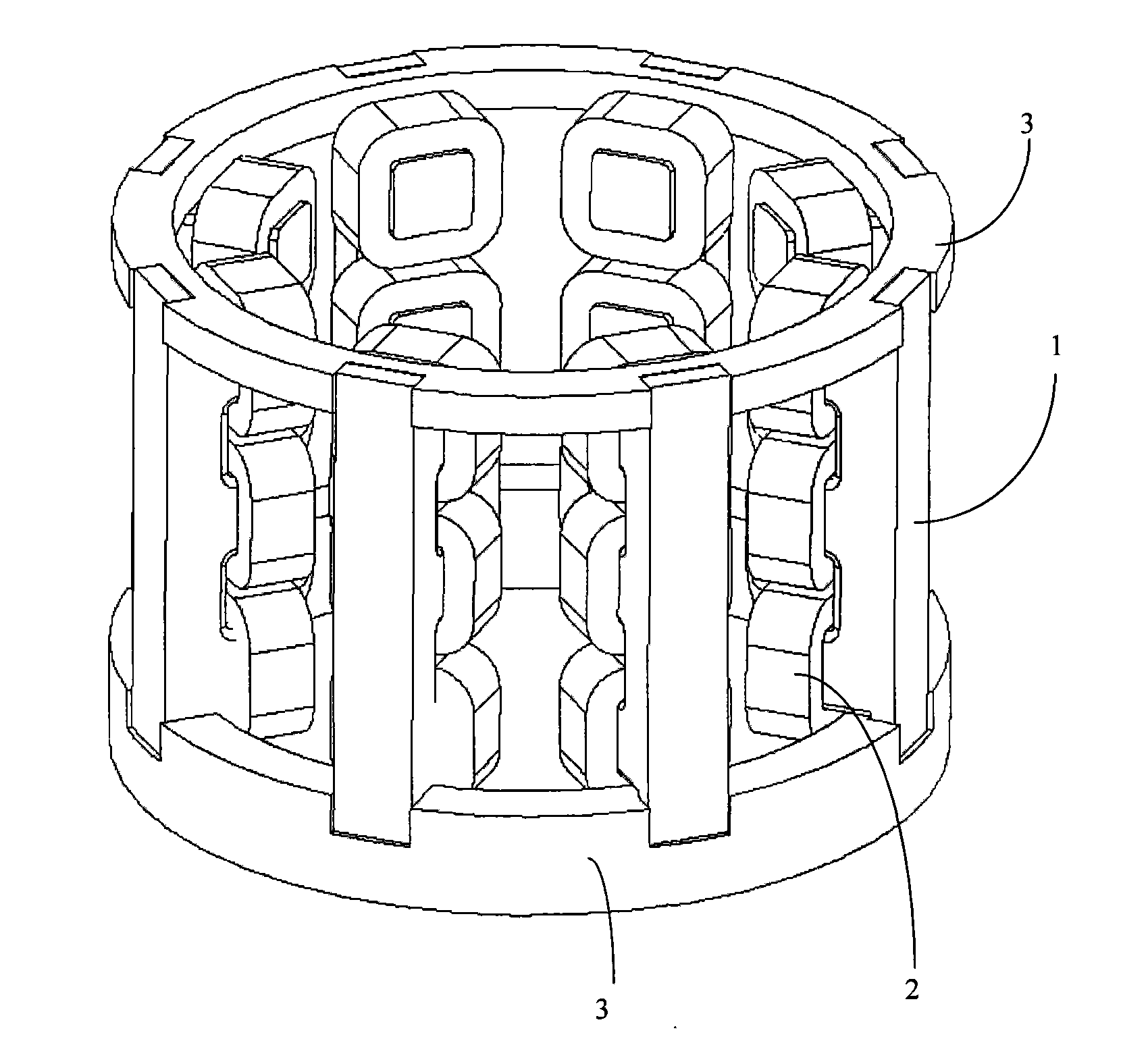

[0028] The present invention includes a casing 10 and a stator and a mover inside it. Such as figure 2 and image 3 As shown, the stator includes two ring-shaped yoke support rings 3, and eight strip-shaped stator yokes 1 evenly distributed along the ring are arranged between the two yoke support rings. The inner surface of the stator yoke 1 is Alveolar structure, the alveolar structure includes three stator teeth 102, and two stator slots 103 are formed between adjacent stator teeth. Stator coils 2 are placed on the slot structure, and after the stator coils 2 are energized, the magnetic poles of adjacent stator teeth are opposite. refer to Figure 4 and 5 , both ends of the stator yoke 1 have boss structures 101, and the yoke support ring 3 is evenly distributed with groove structures 301 along the outer circumferential direction, through the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com