Preparation method of metal soft magnetic powder core

A metal soft magnetic and magnetic powder technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of poor magnetic performance stability, high pollution, high cost, and achieve low cost, low raw material cost and high quality factor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

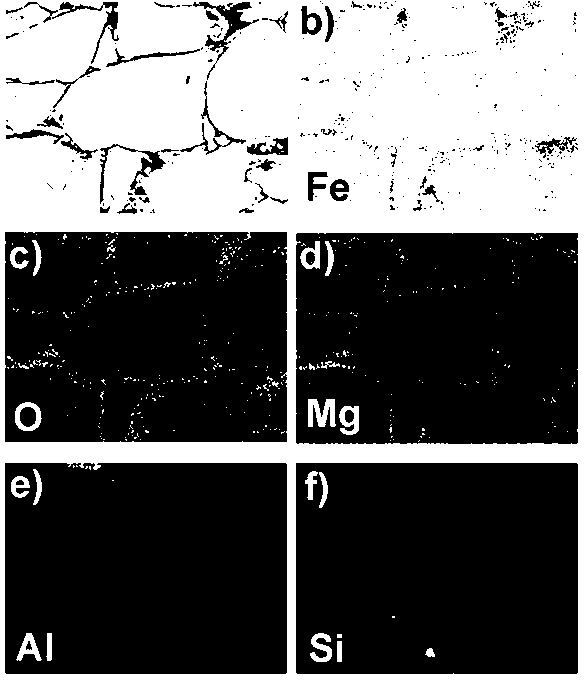

[0026] Sieve 300g iron-silicon metal magnetic powder with a 150-mesh sieve, and add nano-SiO 11.7% of the magnetic powder weight to the magnetic powder 2 Dispersion liquid and 0.5% sodium silicate powder, in which nano-SiO 2 SiO in dispersion 2 The weight concentration is 18.5%. After stirring evenly, heat to 60°C and keep stirring until the magnetic powder slurry is dry. Grind the dried magnetic powder slurry to obtain coated magnetic powder; add 0.5% of the weight of the coated magnetic powder to the coated magnetic powder Zinc stearate powder and mixed evenly, then put into the hydroforming machine, using 21.7 tons / cm 2 Φ26.92×Φ14.73×11.18, that is, an annular powder core with an outer diameter of 26.92mm, an inner diameter of 14.73mm, and a height of 11.18mm; the powder core is heated in a tube furnace with nitrogen as a protective atmosphere Heat it to 750°C and keep it warm for 30 minutes, then cool it in the furnace; finally, spray a layer of epoxy resin insulating va...

Embodiment 2

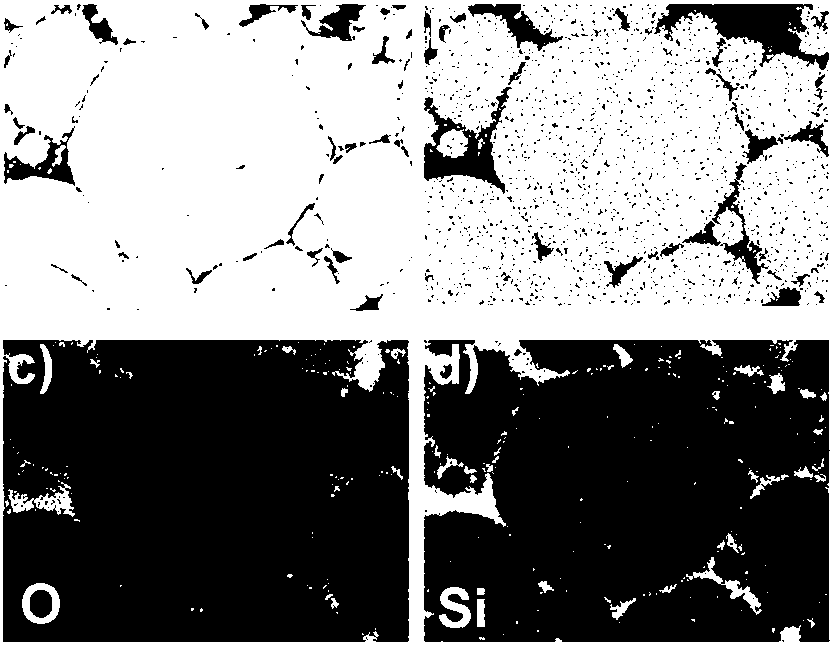

[0033] Get 300g sendust metal magnetic powder with 150 mesh sieves, add the nano-MgO dispersion liquid that accounts for 6.7% of magnetic powder weight and the sodium silicate powder of 0.8% to magnetic powder, wherein the MgO weight concentration is 35% in the nano-MgO dispersion liquid, After stirring evenly, heat it to 80°C and keep it warm, and keep stirring until the magnetic powder slurry is dry. Grind the dried magnetic powder slurry to obtain coated magnetic powder; add zinc stearate powder accounting for 0.3% of the weight of the coated magnetic powder to the coated magnetic powder. And mix evenly, then put into the hydroforming machine, use 18.3 tons / cm 2 Φ26.92×Φ14.73×11.18, that is, an annular powder core with an outer diameter of 26.92mm, an inner diameter of 14.73mm, and a height of 11.18mm; the powder core is heated in a tube furnace with nitrogen as a protective atmosphere Heat it to 700°C and keep it warm for 50 minutes, then cool it with the furnace; finally,...

Embodiment 3

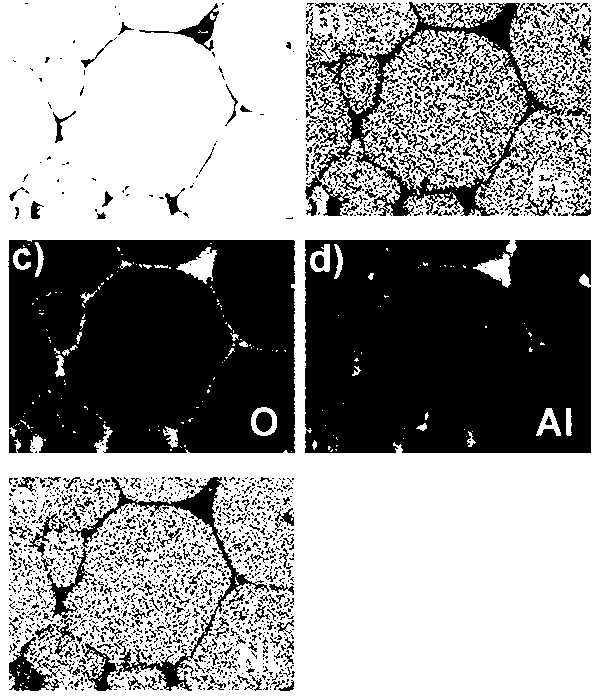

[0040] Sieve 300g of iron-nickel metal magnetic powder with a 150-mesh sieve, and add nano-Al which accounts for 33% of the magnetic powder weight to the magnetic powder 2 o 3 Dispersion liquid and 1.2% sodium silicate powder, in which nano-Al 2 o 3 Al in the dispersion 2 o 3 The weight concentration is 5%, after stirring evenly, heat it to 50°C, keep it warm and keep stirring until the magnetic powder slurry is dry, and grind the dried magnetic powder slurry to obtain coated magnetic powder; add 1.0% of the weight of the coated magnetic powder to the coated magnetic powder Zinc stearate powder and mixed evenly, then put into the hydroforming machine, using 12.4 tons / cm 2 Φ26.92×Φ14.73×11.18, that is, an annular powder core with an outer diameter of 26.92mm, an inner diameter of 14.73mm, and a height of 11.18mm; the powder core is heated in a tube furnace with hydrogen as a protective atmosphere Heat it to 500°C and keep it warm for 120 minutes, then cool it with the furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| inductance | aaaaa | aaaaa |

| inductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com