A material and a method for improving the density of a magnetic powder core insulating layer

A magnetic powder core and magnetic powder technology, applied in the fields of inorganic material magnetism, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problem that the coating thickness and distribution state affect the pressing performance, the degree of mold damage, less industrial applications, and more synthesis steps, etc. problem, to achieve good magnetic performance stability, cost-free pollution, and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

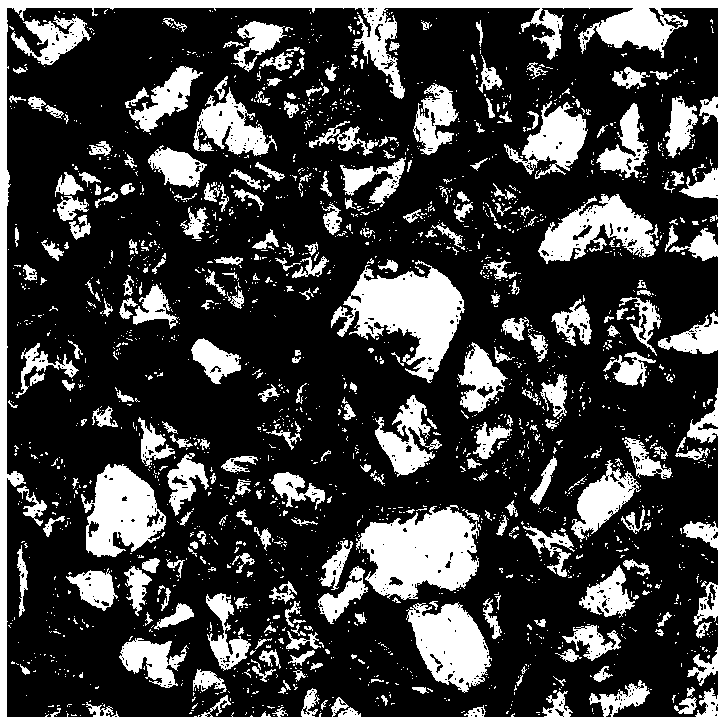

[0026] Step 1) Take 1 kg of sendust magnetic powder produced by ordinary crushing method, and sieve it through a 140-mesh sieve, and the magnetic powder particle size is 30-77 μm, accounting for more than 95%;

[0027] Step 2) Add a metal surface modifier accounting for 2% of the weight of the metal magnetic powder to the metal magnetic powder. In order to disperse the surface modifier better, use 10 g of water as a diluent, stir the metal magnetic powder evenly, and react for 15 minutes to form a dry magnetic powder. material;

[0028] Step 3) Insulation coating: Pour 3.5g of phosphoric acid into the dry slurry, mix and stir, add 15g of water as a diluent, stir the magnetic powder for more than 15min to form a magnetic powder slurry, heat the slurry to 40°C-80°C and keep it warm Stir until the magnetic powder slurry is dry;

[0029] Step 4) Pour the inorganic insulating powder glass powder into the slurry obtained in step 3), mix and stir, dry and grind to obtain coated magn...

Embodiment 2

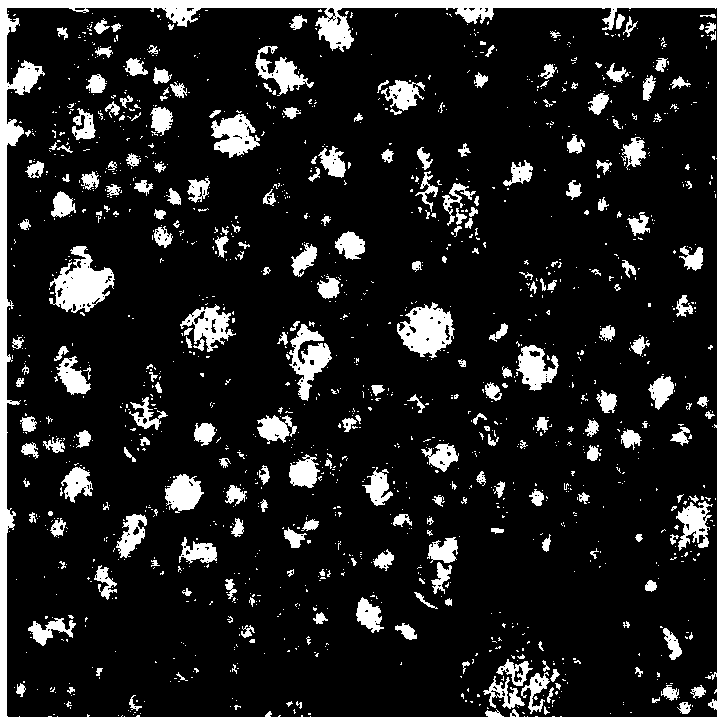

[0040] Step 1) Take 1 kg of iron-silicon magnetic powder prepared by gas atomization method, and sieve it through a 160-mesh sieve, and the magnetic powder particle size is 30-77 μm, accounting for more than 95%;

[0041] Step 2) Add a metal surface modifier accounting for 2.5% of the weight of the metal magnetic powder to the metal magnetic powder. In order to disperse the surface modifier better, use 8g of water as a diluent, stir the metal magnetic powder evenly, and react for 15 minutes to form a dry magnetic powder. material;

[0042] Step 3) Insulation coating: Pour 4.5g of phosphoric acid into the dry slurry, mix and stir, add 15g of absolute ethanol as a diluent, stir the magnetic powder for more than 20 minutes to form a magnetic powder slurry, make it fully react and dry;

[0043] Step 4) Pour the inorganic insulating powder kaolin powder into the slurry, mix and stir, grind after drying to obtain the coated magnetic powder; the powder coated with insulation can be o...

Embodiment 3

[0054] Step 1) Take 1 kg of sendust magnetic powder prepared by vacuum smelting and crushing method, pass through a 140-mesh sieve, and the magnetic powder particle size is 30-77 μm, accounting for more than 95%;

[0055] Step 2) Add a metal surface modifier accounting for 1.8% of the weight of the metal magnetic powder to the metal magnetic powder. In order to disperse the surface modifier better, use 10 g of water as a diluent, stir the metal magnetic powder evenly, and react for 15 minutes to form a dry magnetic powder. material;

[0056] Step 3) Insulation coating: Pour 4.5g of phosphoric acid into the dry slurry, mix and stir, add 15.5g of water as a diluent, stir the magnetic powder for more than 15min to form a magnetic powder slurry, heat the slurry to 40°C-80°C and keep it warm. Stir continuously until the magnetic powder slurry is dry;

[0057] Step 4) Pour the inorganic insulating powder glass powder into the slurry, mix and stir, dry and grind to obtain the coated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com