Demountable longitudinal mode guided wave magnetostrictive sensor based on operating cane

A longitudinal mode, magnetostrictive technology, used in instruments, measuring devices, scientific instruments, etc., can solve the problems of step-by-step installation of magnetostrictive sensors, and achieve rapid disassembly and assembly, high magnetostriction coefficient, and static magnetic field distribution. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

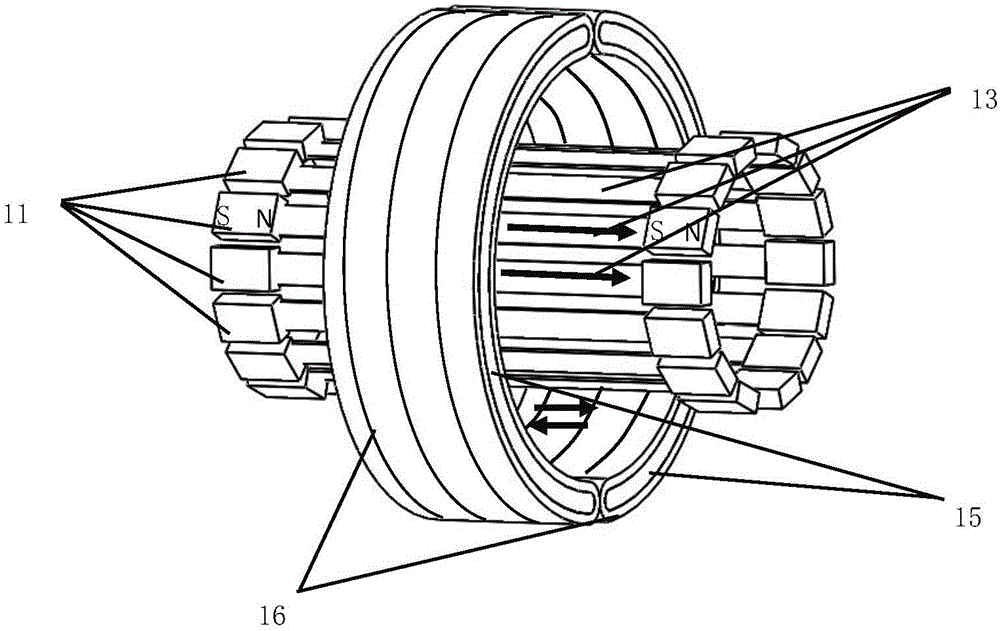

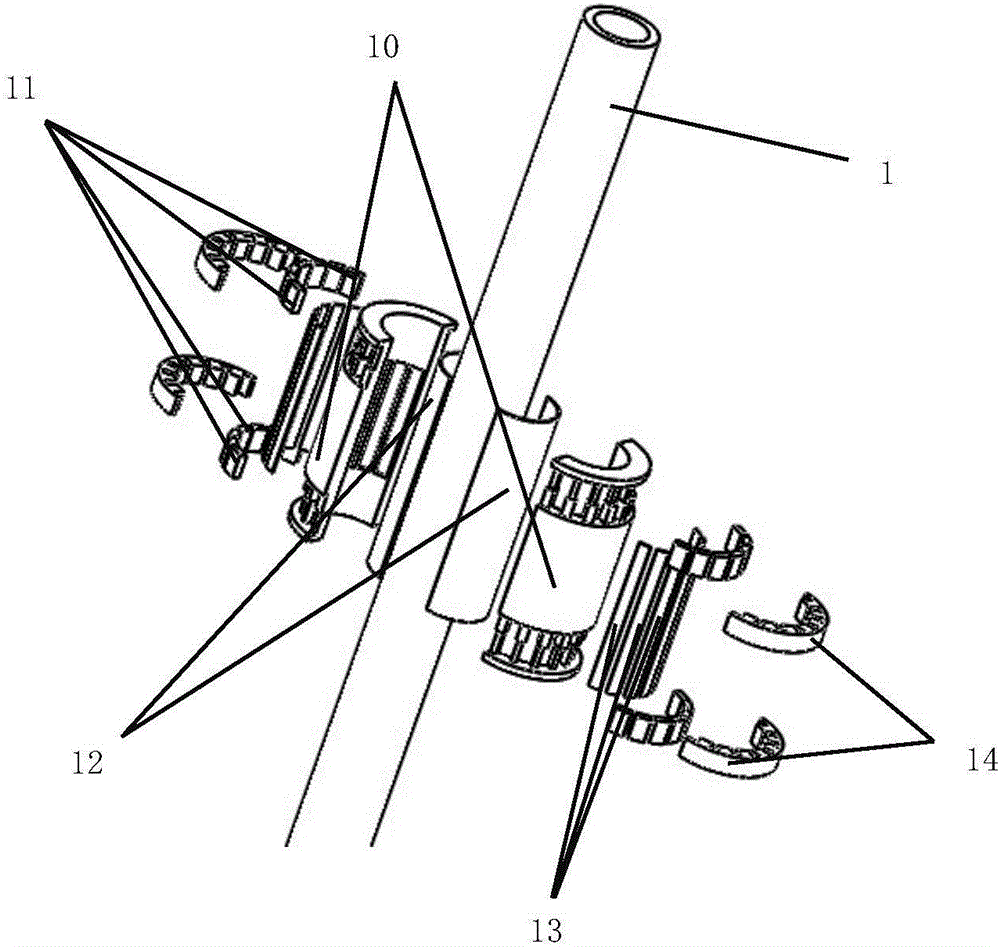

[0022] According to the content of the above invention, the detachable longitudinal mode guided wave magnetostrictive sensor based on the operating stick can provide the following implementation methods.

[0023] In the iron-cobalt alloy shell cage, the middle part of the iron-cobalt alloy thin strip 13 is coated with a cured epoxy resin layer, which is used for contacting the measured tube (or rod) 1 . The iron-cobalt alloy shell cage and the crescent-shaped detection coil 16 are placed in the base 2, and the distance between the two C-shaped elements is controlled by adjusting the displacement adjustment nut 5 to achieve the purpose of loading.

[0024] The present invention will be further described below in conjunction with the accompanying drawings and the above embodiments, and the specific implementation examples provided below are only descriptive, not restrictive, and cannot be used to limit the protection scope of the present invention.

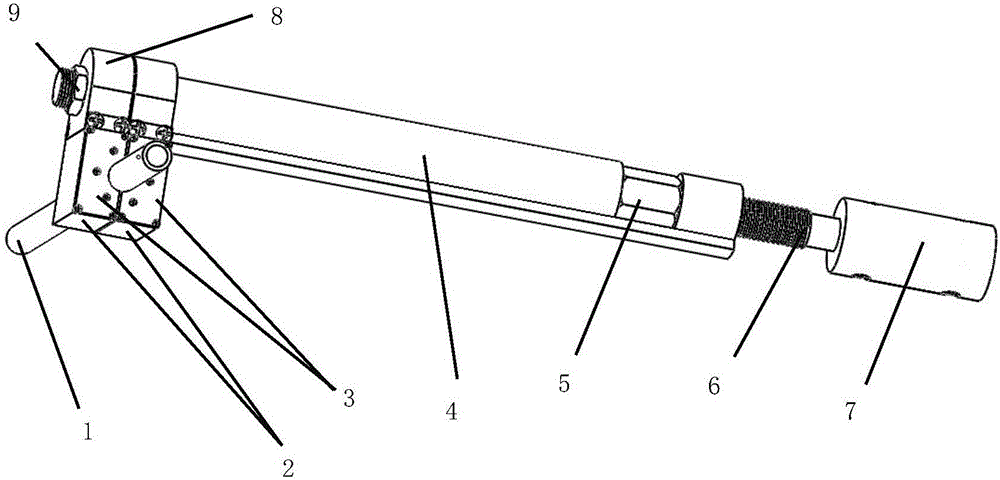

[0025] figure 1 It is an ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com