Large-amorphous forming capacity iron-based block amorphous magnetic alloy material and preparation method thereof

A magnetic alloy and amorphous technology, which is applied in the field of iron-based bulk amorphous magnetic alloy materials with large amorphous forming ability and its preparation, can solve the problem of poor amorphous forming ability of iron-based amorphous alloys, small magnetostriction coefficient, Can not do other problems, to achieve the effect of excellent soft magnetic properties, high magnetostriction coefficient, large amorphous formation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

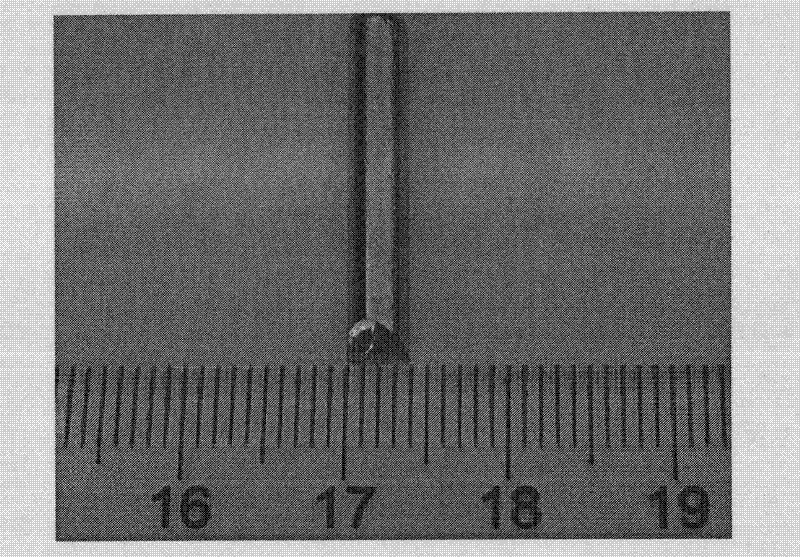

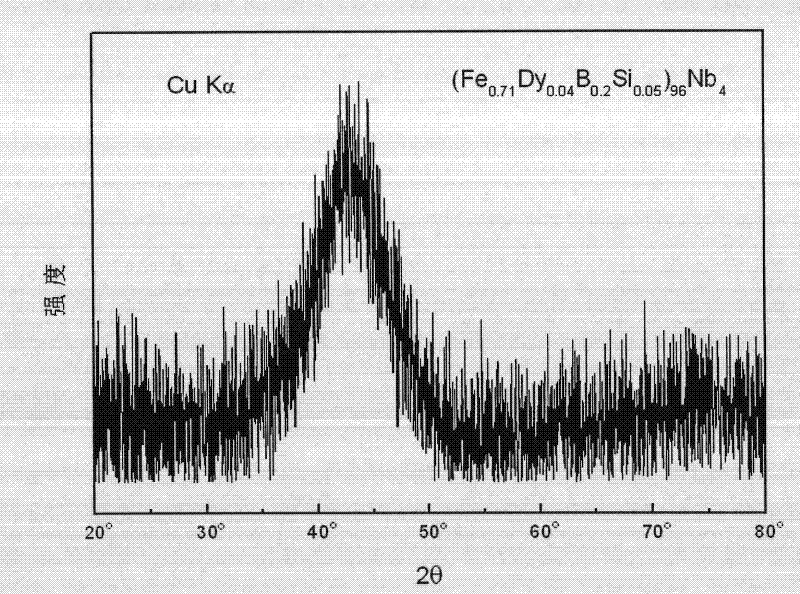

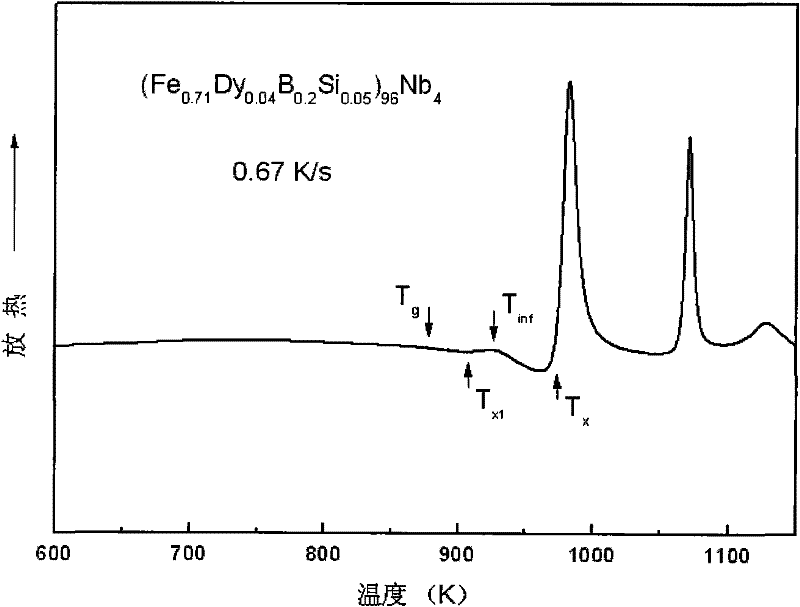

[0030] Prepare a diameter of 4mm (Fe 0.71 Dy 0.04 B 0.2 Si 0.05 ) 0.96 Nb 0.04Bulk amorphous magnetic alloy rods.

[0031] The specific preparation method is as follows:

[0032] Step 1: Pure metal Fe, Si, B, Nb, Dy elements with a purity of more than 99% according to the molecular formula (Fe 0.71 Dy 0.04 B 0.2 Si 0.05 ) 0.96 Nb 0.04 The atomic percentage in the preparation of raw materials;

[0033] Step 2: Put the raw materials prepared in step 1 in the water-cooled copper crucible of the electric arc melting furnace, and first evacuate to 10 -5 Pa, then fill it with argon until the pressure is 600mbar for smelting, and then continue smelting for 5 minutes after melting, then let the alloy cool with the copper crucible until it solidifies, turn it over quickly, and repeatedly smelt 3 to 5 times to obtain an alloy with uniform composition ingot;

[0034] Step 3: Grind the alloy ingot obtained in step 2 to remove surface impurities, then place it in alcohol for ...

Embodiment 2

[0041] Prepare a diameter of 3.5mm (Fe 0.7 Tb 0.05 B 0.2 Si 0.05 ) 0.96 Nb 0.04 Bulk amorphous magnetic alloy rods.

[0042] The specific preparation method is as follows:

[0043] Step 1: the pure metal Fe, Si, B, Nb, Tb elements with a purity of more than 99% according to the molecular formula (Fe 0.7 Tb 0.05 B 0.2 Si 0.05 ) 0.96 Nb 0.04 The atomic percentage in the preparation of raw materials;

[0044] Step 2: Put the raw materials prepared in step 1 in the water-cooled copper crucible of the electric arc melting furnace, and first vacuumize to 1.5×10 -5 Pa, then fill it with argon until the pressure is 500mbar for smelting, and then continue smelting for 6 minutes after melting, then let the alloy cool with the copper crucible until it solidifies, turn it over quickly, and repeatedly smelt 3 to 5 times to obtain an alloy with uniform composition ingot;

[0045] Step 3: Grind the alloy ingot obtained in step 2 to remove surface impurities, then place it in al...

Embodiment 3

[0052] Prepare a diameter of 1mm (Fe 0.74 Dy 0.01 B 0.2 Si 0.05 ) 0.96 Nb 0.04 Bulk amorphous magnetic alloy rods.

[0053] The specific preparation method is as follows:

[0054] Step 1: Pure metal Fe, Si, B, Nb, Dy elements with a purity of more than 99% according to the molecular formula (Fe 0.74 Dy 0.01 B 0.2 Si 0.05 ) 0.96 Nb 0.04 The atomic percentage in the preparation of raw materials;

[0055] Step 2: Put the raw materials prepared in step 1 in the water-cooled copper crucible of the electric arc melting furnace, and first vacuumize to 2×10 -5 Pa, then fill it with argon until the pressure is 700mbar for smelting, and then continue smelting for 8 minutes after melting, then let the alloy cool with the copper crucible until it solidifies, then turn it over quickly, and repeatedly smelt 3 to 5 times to obtain an alloy with uniform composition ingot;

[0056] Step 3: Grind the alloy ingot obtained in step 2 to remove surface impurities, then place it in alc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com