Fe-Ga-Ce-B alloy bar and preparation method thereof and cooling copper mold

A fe-ga-ce-b, alloy rod technology, applied in the field of functional material preparation, can solve the problems of unfavorable directional crystallization rods, slow filling cavity speed, and fluidity of alloy liquid, etc., to solve magnetostriction The performance is not high, the effect of improving the magnetostriction coefficient and improving the casting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

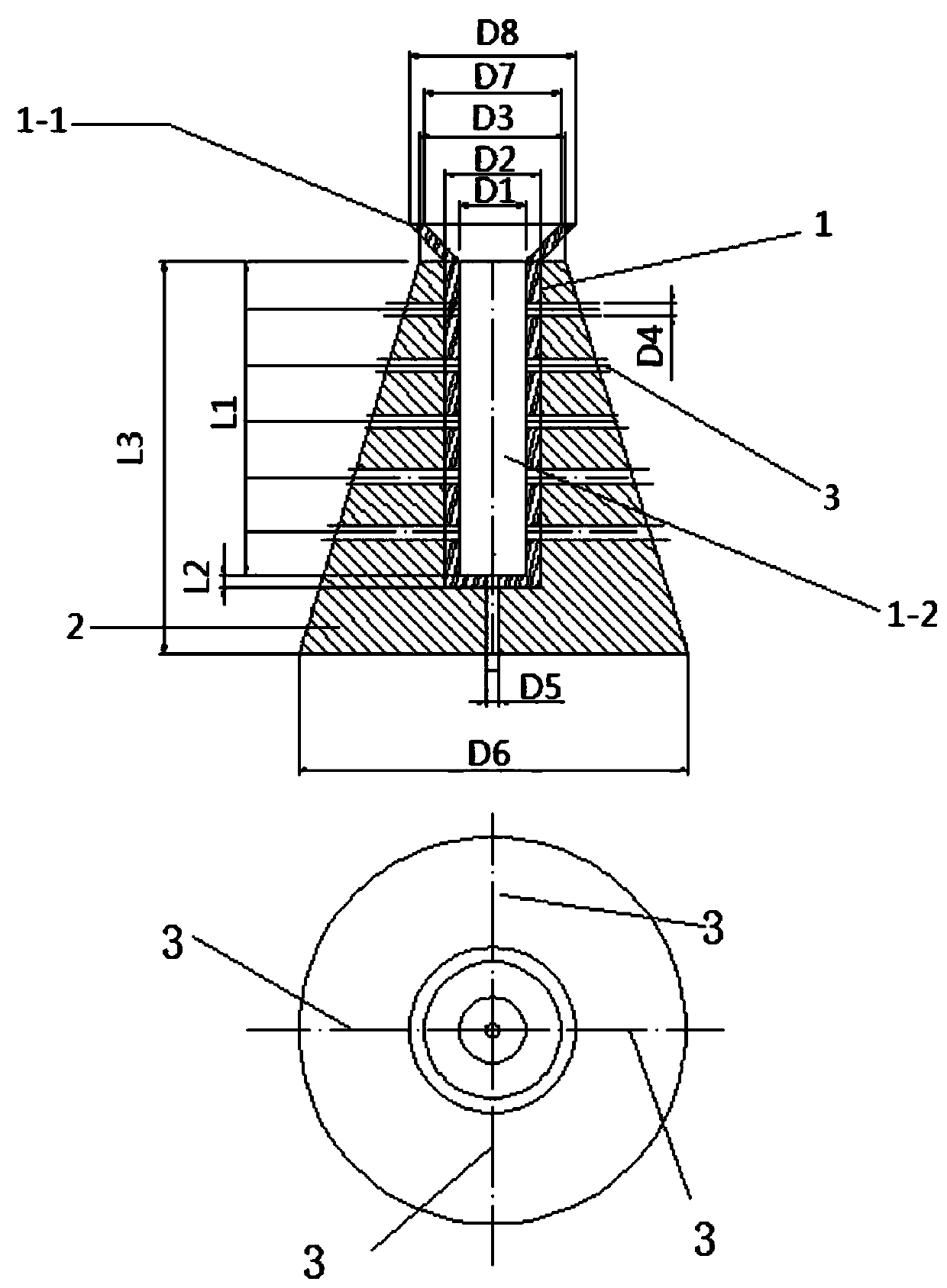

[0037] The invention provides a method for preparing the Fe-Ga-Ce-B alloy rod, comprising the following steps:

[0038] The master alloy of iron, gallium, cerium and iron boron is vacuum smelted under a protective atmosphere, and the alloy master ingot is obtained after solidification;

[0039] The alloy master ingot is melted and then flowed into the cooling copper mold described in the above scheme for gradient cooling to obtain the Fe-Ga-Ce-B alloy rod.

[0040] In the invention, the intermediate alloy of iron, gallium, cerium and iron-boron is vacuum smelted under a protective atmosphere. In the present invention, the purity of the iron, gallium and cerium is preferably 99.99%; the iron-boron master alloy is preferably Fe-20B master alloy. In the present invention, the mass of the iron, gallium, cerium and iron-boron master alloy is configured according to the atomic ratio of each element in the Fe-Ga-Ce-B alloy rod. In the present invention, there is no special requirem...

Embodiment 1

[0059] (1) Select Fe, Ga, Ce and Fe-20B master alloy powder with a purity of 99.99% according to Fe 81.2 Ga 17 Ce 0.8 B 1 (atomic ratio) target composition formulation Prepare various raw materials.

[0060] (2) High-purity Fe is placed in the bottom non-porous quartz crucible, then the crucible is placed in the induction coil in the vacuum furnace, and high-purity Ga, Ce, and Fe-20B master alloy are placed in the feeding bin, Pass circulating cooling water, close the furnace door, first turn on the vacuum mechanical pump and the Roots pump in order to evacuate the vacuum furnace to 1×10 2 Below Pa, turn on the diffusion pump to evacuate the vacuum furnace to 10 -2 Below Pa; then feed high-purity Ar gas until the pressure in the furnace is less than 0.05Pa; then turn on the power, preheat the quartz crucible and high-purity Fe with a current of 500A for 2min, and then increase the current to 1400A; wait until the pure Fe is melted After 1 / 3~1 / 2, rotate the feeder to add t...

Embodiment 2

[0069] (1) Select Fe, Ga, Ce and Fe-20B master alloy powder with a purity of 99.99% according to Fe 79.2 Ga 19 Ce 0.6 B 1.2 (atomic ratio) target composition formulation Prepare various raw materials.

[0070] (2) High-purity Fe is placed in the bottom non-porous quartz crucible, then the crucible is placed in the induction coil in the vacuum furnace, and high-purity Ga, Ce, and Fe-20B master alloy are placed in the feeding bin, Pass circulating cooling water, close the furnace door, first turn on the vacuum mechanical pump and the Roots pump in order to evacuate the vacuum furnace to 1×10 2 Below Pa, turn on the diffusion pump to evacuate the vacuum furnace to 10 -2 Below Pa; then feed high-purity Ar gas until the pressure in the furnace is less than 0.05Pa; then turn on the power, preheat the quartz crucible and high-purity Fe with a current of 500A for 2min, and then increase the current to 1350A; wait until the pure Fe is melted After 1 / 3~1 / 2, rotate the feeder to add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com